Commissioning and acceptance of standby generator set in data center

As the backup power supply of the data center, the diesel generator set is an important force for the data center to deal with natural disasters such as typhoon and earthquake. In order to ensure the normal use of the diesel generator set in the data center, it is necessary to conduct commissioning and acceptance before putting it into operation. The diesel generator set can be put into normal use only after strict technical acceptance and when its safety, power characteristics, power quality, noise and other performance indicators meet the standards.

1. Acceptance of unit installation quality

The installation quality of the unit must meet the installation requirements of the diesel generator set. During the installation of the diesel generator set, consideration should be given to: the load of the foundation, the location of the pedestrian passage and maintenance, the vibration of the unit, ventilation and heat dissipation, the connection of the exhaust pipe, heat insulation, noise reduction, the size and location of the fuel tank, as well as the relevant national and local buildings Environmental protection regulations and standards and other major factors. During the installation quality acceptance of the unit, the acceptance shall be carried out item by item according to the installation of the unit and the building design requirements of the machine room.

(1) Layout principle of unit in machine room

The air inlet and exhaust pipes and smoke exhaust pipes shall be laid overhead on both sides of the unit against the wall, and the height shall be more than 2.2m. The smoke exhaust pipes are generally arranged on the back of the unit.

The installation, maintenance and handling channels of the unit shall be arranged on the operating surface of the unit in the machine room arranged in parallel. In the machine room arranged in parallel, the cylinder is a vertical single row unit, which is generally arranged at one end of the diesel engine, while the V-shaped diesel generator set is generally arranged at one end of the generator. For the machine room with two parallel rows, the installation, maintenance and handling channels of the units shall be arranged between the two rows of units.

The height of the machine room shall be the height required for lifting the piston, connecting rod and crankshaft through the manual hoist with the reserved hook during the installation and maintenance of the unit.

Cables, cooling water and fuel oil pipes shall be set on the supports in the trenches on both sides of the unit, and the net depth of the trenches is generally 0.5~0.8m.

(2) Architectural design requirements of machine room

The machine room shall be equipped with access, passageway and door hole convenient for the transportation of large equipment such as diesel generator set and control panel, so as to facilitate the installation, transportation and repair of equipment.

2-3 lifting hooks shall be reserved above the longitudinal centerline of the unit, and their height shall be able to lift out the piston and connecting rod components of the diesel engine, so as to facilitate the installation and maintenance of the unit.

The pipes for laying cables, cooling water and fuel oil in the machine room shall have a certain slope to facilitate the drainage of accumulated water. The cover plate of the trench shall be steel plate cover plate, reinforced concrete cover plate or fireproof treated wood cover plate.

For machine rooms with control rooms, observation holes shall be set on the partition walls of control rooms and machine rooms.

For the machine room designed together with the main building, sound insulation and noise reduction shall be carried out.

The ground of the machine room shall be made of calendered cement, terrazzo or quarry tile, and the ground shall be able to prevent oil from seeping in.

Certain damping and isolation measures shall be taken between the foundation of the unit and the surrounding ground, as well as between the units, to reduce the damage caused by vibration. The foundation surface with public chassis shall be 50~100mm higher than the ground, and anti oil measures shall be taken. The foundation surface shall be provided with drainage ditches and floor drains to remove oil stains on the foundation surface.

(3) Installation requirements for fixed units

Installation position: the generator set can be installed in the basement, ground and roof. The machine room of the generator set shall be near the power distribution room for wiring, use and maintenance. However, it should not be too close to the communication machine room to prevent the vibration, noise and pollution generated by the unit during operation from affecting the communication effect of the communication equipment.

2、 Unit commissioning

(1) Commissioning preparation

Commissioning environment inspection

The commissioning environment shall be clean and tidy without dust and sundries. The smoke, oil and water pipes of the unit shall be smooth.

(2) Quality inspection before unit startup

Check the appearance quality of the unit one by one according to the order of radiator, oil engine, control panel, generator, chassis and distribution cabinet, including welding quality, wiring quality, three leakage conditions, parts quality and overall quality.

Welding quality: the welding of the unit shall be firm, the weld shall be uniform, and there shall be no defects such as weld penetration, undercut, slag inclusion and air holes. The welding slag and flux shall be cleaned, and the paint film of the painted part shall be uniform, without obvious cracks and falling off;

Wiring quality: all wires are in good contact, firmly fastened, clearly marked and correctly connected. The electrical installation of the unit shall comply with the circuit diagram, and the phase sequence of the terminal blocks of the unit control panel shall be arranged from left to right or from top to bottom from the front of the panel. The connection of each line shall be provided with obvious signs that are not easy to fall off. The signs such as nameplate, direction sign, grounding sign, etc. shall be set firmly, the contents shall be clear and accurate, and good grounding terminals shall be set. The nameplate of the unit shall include the following contents: a. Unit name; H Rated current; b. Unit model; i. Rated power factor; c. Phase number; j. Mass, Kg; d. Rated speed, r/min; k. Name of manufacturer; e. Rated frequency, Hz; l. Unit number; f. Rated power, KW; m. Ex factory date; g. Rated voltage, V; n. Standard code and number.

Three leakage conditions: the unit shall be free of oil, water and gas leakage (check after startup);

Quality of parts and components: diesel engine, generator, control panel, distribution cabinet and other parts and components shall be intact without obvious scratches and cracks on the surface, control panel instruments shall be free of damage, and the surface shall be clean;

Overall quality: all parts are fixed and connected reliably, and the whole machine is free of missing parts, nuts, washers, etc. There shall be no sundries and metal objects inside the unit, especially the control panel and distribution cabinet.

The minimum distance between exposed conductors of different phases in the equipment junction box and between conductors and the ground shall meet the insulation requirements of different voltage levels, otherwise insulation protection measures shall be taken.

If the switchgear, automatic or manual switching device and protection device of the distribution cabinet pass the test, the load test shall be carried out according to the designed distribution plan for the use of self-contained power supply. The grounding or neutral connection of bare conductors for grounding shall be reliable.

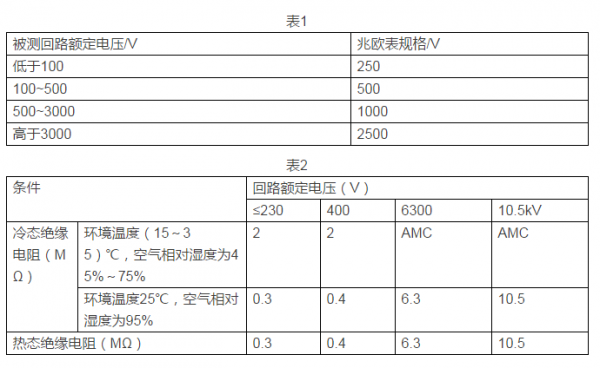

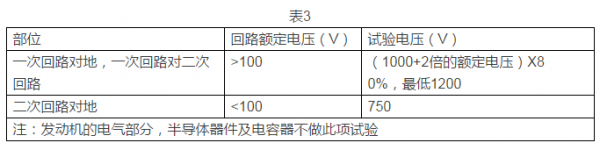

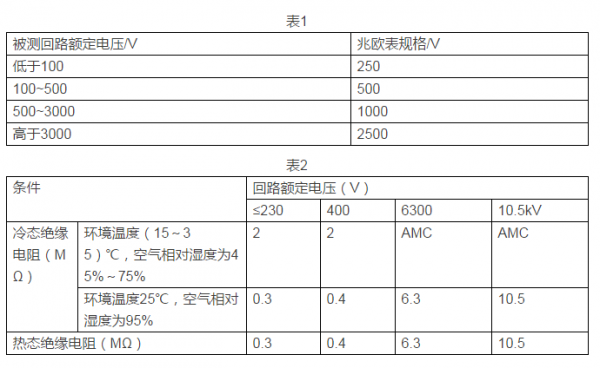

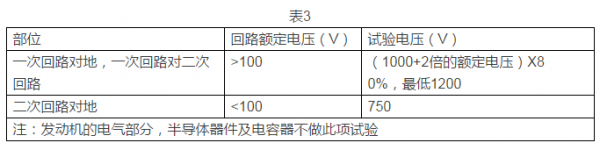

Measure the insulation resistance. Measure the insulation resistance of each independent electrical circuit to the ground and between circuits with a megger (refer to Table 1 for specification selection). During measurement, semiconductor devices, capacitors, etc. shall be removed and all switches shall be in the ON position. When the indication of the megger is stable, read again, and record the ambient temperature and air relative humidity. The test results shall meet the requirements in Table 2.

Insulation dielectric strength test This test is used to test the insulation dielectric strength of each independent electrical circuit to the ground and between circuits. During the test, the power supply shall be connected and the voltage shall be increased to the full value evenly or in sections by 5% of the voltage not exceeding the full value. The time for the voltage to increase from the half value to the full value shall not be less than 10s. The full value voltage test shall last for 1min, and then the voltage shall be reduced. After the voltage drops to one-third of the full value, the power supply shall be cut off and the tested circuit shall be discharged to the ground. The recorded ambient temperature, relative air temperature, atmospheric pressure and test results shall meet the relevant provisions of GB/T2820 (see Table 3 for the specific values of the test voltage).

After the above tests are qualified, the startup test can be carried out.