Listening to the railing and averting danger -- Analysis of electromagnetic hazards in power distribution system

1、 Listen to the sound on the railing, sensitive to the heart

For IDC operation and maintenance personnel, voice is an information source that cannot be ignored in daily inspection and maintenance. Taking the power distribution system as an example, the operation of transformers, low-voltage power distribution cabinets and UPS may produce obvious noise, which is generally considered to be caused by excessive current, and whether the noise is stable and consistent is taken as the standard to judge whether the equipment operates normally.

One day, during routine inspection in an old data center, the inspectors found that there was obvious noise on the floor where the machine room was located, but they were unable to locate the sound source and cause. So IDC operation and maintenance personnel checked the adjacent floors, and found the sound source in the spare parts warehouse at the corner of the machine room floor (the warehouse is two doors away from the place where the patrol inspectors heard the sound, and you can imagine how loud the noise is). However, the preliminary inspection found that the warehouse did not have operating equipment, so where did the abnormal noise come from? For a while, I was full of doubts and didn't know why.

2、 Follow the vine to find out the truth

According to the change of noise intensity, IDC operation and maintenance personnel immediately conducted a comprehensive inspection of the warehouse again. At this time, the two strong wire trunkings in the corner attracted everyone's attention. After careful observation, it was found that there was severe vibration in the two wire trunkings, which caused the resonance of the ceiling when being hoisted. At the same time, the surface temperature of the wire trunking was up to 40 ℃ or more.

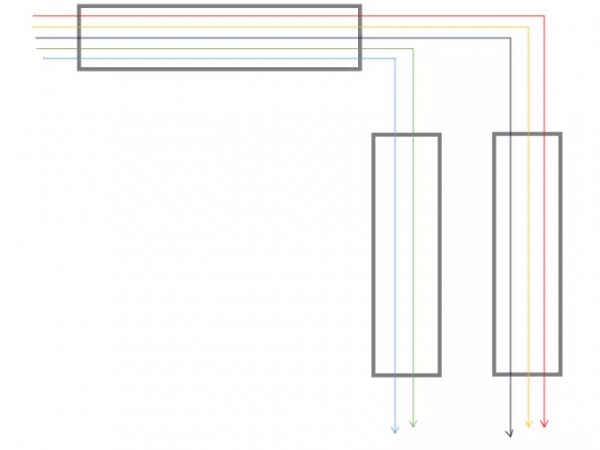

After preliminary analysis, it is ruled out that the short circuit is caused by eddy current, but why is there such strong abnormal noise? In order to find out the specific reasons, the cable trough cover plate was removed at the site and the cable was inspected. It was found that the surface temperature of the cable was very high, and some positions even had bulges and oil seepage; At the same time, when the cable trough cover is removed, the vibration and noise are significantly reduced, and the temperature is gradually reduced. In the next troubleshooting, a special phenomenon was found that the strongest vibration was in a section of trunking that vertically crossed the floor, while the horizontal trunking vibration was very small. The only difference is that there is only one horizontal trunking, which is then divided into two and extended to two vertical trunkings; The 28 cables in the horizontal trunking are arranged in two vertical trunkings in a group of 16 and 12 cables respectively (this is a cross floor cable, 2 groups in total; 3 phase neutral lines, 2 ground lines, 14 lines in a group).

So far, the cause of vibration and noise has been preliminarily identified as eddy current. But what makes people wonder is why the shock is so great? Why does the vibration and temperature decrease significantly after removing the trunking cover plate?

Figure 1 Schematic diagram of trunking and cable layout

3、 Exfoliate the cocoon, its meaning shows itself

As we mentioned earlier, the noise generated by transformer, low voltage distribution cabinet and UPS operation is mostly attributed to excessive current; However, for cables carrying high current, vibration and abnormal noise are seldom seen, and it is easy to lack attention at ordinary times, so the above doubts appear. The following author analyzes the principle:

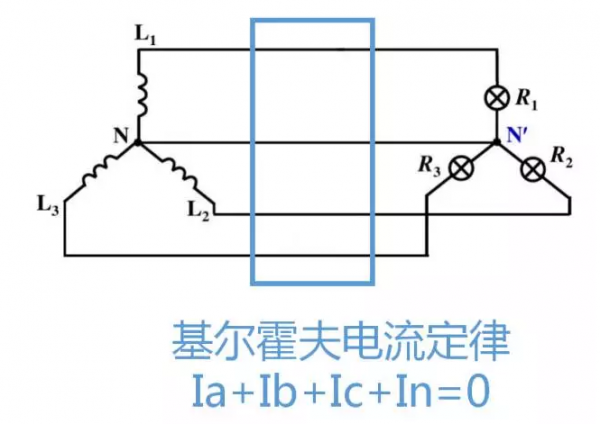

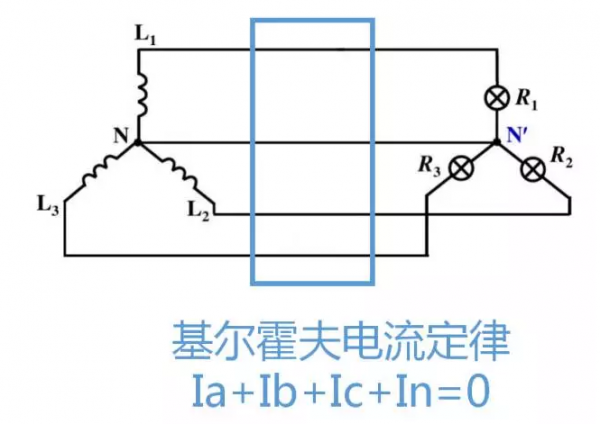

According to Kirchhoff's current law, the sum of the current passing through a group of cables in the blue box (which can be imagined as a section of trunking) at any time is zero.

If we look at the direction of the magnetic field from the cross section of the cable in another direction, the total current is zero, then the magnetic field intensity generated will also cancel each other very close to zero. If phase failure occurs, the total current will not be zero, and the intensity of the induced magnetic field must not be zero.

Therefore, according to the number of cables in the previous slot, the same group of cables are placed in different slots when they are vertically routed, which inevitably leads to the sum of currents in the same slot is not zero, so the corresponding magnetic field strength is not zero.

The trunking is metal and will be affected by the magnetic force itself. When the alternating current in the cable frequently changes the direction of the magnetic field with a frequency of 50Hz, the metal trunking will be affected by the magnetic force and produce vibration; At the same time, the magnetic fields between multiple cables will also affect each other and cause the vibration of the cable itself, so there will be such a violent vibration.

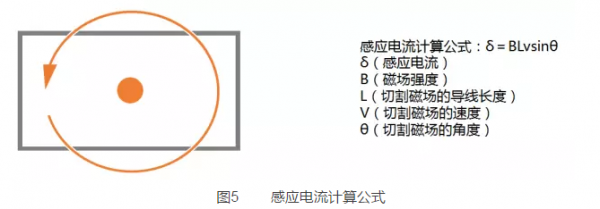

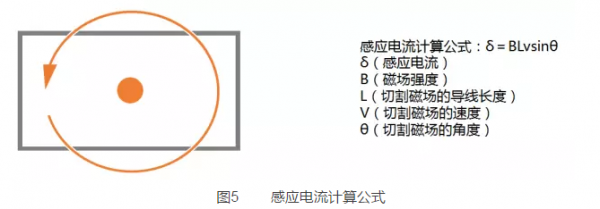

Next, the second problem is that when the trunking cover is closed, the trunking is equivalent to forming a closed conductor around the magnetic field. According to the law of electromagnetic induction, when a part of the conductor of a closed circuit cuts the magnetic induction line in the magnetic field, current will be generated in the conductor. The closed trunking with violent vibration is like the movement of multiple coils tied together to cut the magnetic induction line rapidly, which forms current inside the conductor and heats the trunking. When the cover plate is removed, the metal area affected by the magnetic field is smaller, and the vibration is also smaller. Without the condition of closed conductor, the heating effect of current also disappears.

4、 Suit the medicine to the case and save the day

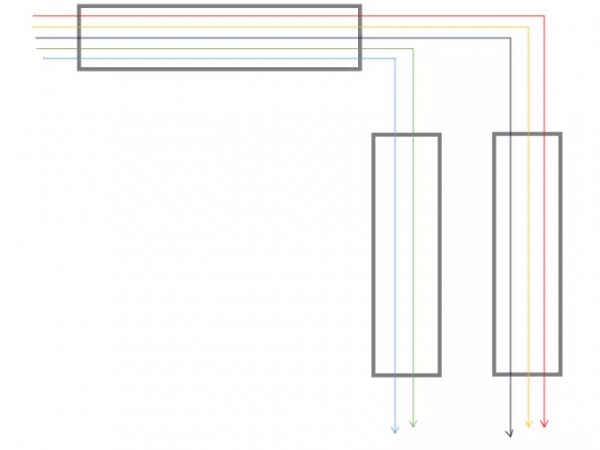

Based on the above analysis, we improved the trunking and moved all cables into the same trunking. As a result, the vibration became very slight as expected, and only when we were close to the cable could we hear some faint sound.

Why is the noise of low-voltage distribution cabinet much greater than that of trunking under normal conditions? We know that the small vibration of the trunking is due to the fact that most of the magnetic fields of the cables cancel each other, but the distance between each bus bar in the distribution cabinet is increased to prevent short circuit, and it usually turns at a 90 degree angle, so the magnetic field cannot effectively cancel, so the strongest vibration of the bus bar is always at the corner connection. The reason why the noise of the transformer is greater than that of the low-voltage distribution cabinet is that the copper bars on the low-voltage side are arranged in a row and the distance is longer.

Returning to this hidden trouble case, the reason for this hidden trouble is that the newly added trunking space during the second phase expansion of the machine room is too small, and the construction personnel will place two groups of cables in different trunkings. This time, the problem was just outside the routine inspection route. It was found that the load increase caused more noise; If the load continues to increase, it is likely to cause the trunking heating to melt the cable insulation layer, causing short circuit or even fire!

Therefore, in the construction and expansion of computer rooms, we need to pay more attention to the lines. In addition to switches, capacitors, bus connection points and other high-risk nodes in the regular routine inspection items of the distribution system, the line connection sections are usually easy to be ignored, and it is also necessary to conduct a comprehensive inspection.