1、 Basic knowledge of cotton

Cotton is a cloverleaf dicotyledonous plant, belonging to Malvaceae, Malvaceae and Hibiscus subfamily. It likes heat, good light, drought resistance and waterlogging, and is suitable for planting in loose and deep soil.

Cotton cultivation has a long history, starting around 800 BC. China is one of the countries that planted cotton earlier in the world. In the third century BC, the Warring States Period, there were records about cotton planting and spinning in the Shangshu and Houhanshu.

In the history of cotton cultivation in China, four varieties have been planted successively: sea island cotton (long staple cotton), Asian cotton (coarse staple cotton), land cotton (fine staple cotton) and grass cotton (coarse staple cotton). In different historical periods, the main cultivated varieties in China are also different. Asian cotton has the longest history of introduction, the longest planting time, and a wide cultivation area; The introduction of upland cotton into China has a short history, but it has developed rapidly. It replaced Asian cotton in the 1950s. At present, most of the cotton planted in the vast cotton regions is upland cotton (fine staple cotton), and a small amount of island cotton (long staple cotton) is also planted in Xinjiang.

(1) Cotton variety characteristics

Cotton is a perennial, short sunshine crop, which is native to tropical and subtropical regions. After long-term artificial selection and cultivation, it gradually moved north to the temperate zone and evolved into an annual crop. Sowing in spring (or early summer), budding, flowering and fruiting in the same year, the growth cycle is completed, and life ends when winter is cold. In the process of its growth and development, as long as there are sufficient temperature, light, water and fertilizer conditions, like perennial plants, it can continuously grow branches, leaves, buds, flowers, and bolls, and continue to grow and develop, with unlimited growth and strong regeneration ability. During the whole life of cotton, temperature has a great influence on its growth, yield and product quality. In addition to temperature, cotton is very sensitive to light, relatively resistant to drought and afraid of floods. Cotton grows through four seasons: spring, summer, autumn and winter. There are 16 solar terms from the spring equinox to the beginning of winter (from the middle and late April to the middle of November). The whole life of cotton can be divided into five stages: sowing, seedling, bud, flower and boll, and boll opening. Relative to others agriculture products As for cotton, its growth period is relatively long, which is greatly affected by natural factors.

(2) Quality composition of cotton fiber

Cotton fiber is a seed fiber formed from the epidermal cells of the fertilized ovule through elongation and thickening, which is different from the general phloem fiber. Cotton fiber is mainly cellulose, accounting for 93% - 95% of the dry weight, and the rest is fiber companion. Because of its many excellent economic properties, cotton fiber has become the most important raw material for textile industry.

1. Length. At present, the fiber length of upland cotton and island cotton varieties produced in major cotton regions in China is mainly 25-31mm and 33-39mm respectively. The length of cotton fiber refers to the length between the two ends of the fiber after straightening, which is generally expressed in millimeters. The length of cotton fiber varies greatly. The longest fiber can reach 75mm, and the shortest one is only 1mm. Generally, the fiber length of fine staple cotton is 25-33mm, and that of long staple cotton is more than 33mm. The cotton fiber length on different varieties, cotton plants and cotton bolls varies greatly, even among the cottonseeds of the same boll at different petal positions, or even at different seed positions of the same cottonseed. Generally speaking, the fiber of the lower cotton boll is shorter, the fiber of the middle cotton boll is longer, and the fiber length of the upper cotton boll is between the two; In the same cotton boll, the fiber on the middle cotton seed of each seed cotton is longer. Cotton fiber length is one of the most important indicators of fiber quality, which is closely related to spinning quality. When other qualities are the same, the longer the fiber, the higher the spinning count. The number of counts is calculated under the condition of the specified moisture regain (8.5%). When the length of each kilogram of cotton yarn is several meters, it is several metric counts. The finer the yarn, the higher the count. The higher the number of spinning yarns, the smaller the number of spinnable yarns and the greater the strength.

2. Length uniformity. The effect of fiber length on yarn quality is also affected by its evenness. Generally, the tidier the fiber is, the lower the short fiber content is, the smoother the yarn surface is, and the higher the yarn strength is.

Table 1: Relationship between raw cotton length and spinnable count

| Raw cotton type |

Fiber length (mm) |

Fineness (m/g) |

Number of textiles (metric) |

| long-staple cotton |

33--41 |

6500—-8500 |

100--200 |

| Fine pile cotton |

25--31 |

5000--6000 |

33--99 |

| Coarse cotton |

19--23 |

3000--4000 |

15--30 |

Source: Cotton Growth Law and Cultivation with High Quality, High Yield and High Efficiency, Chen Qien and other editors in chief, China Agricultural Publishing House, 1997, page 184.

3. Fiber fineness. The fiber fineness is closely related to the strength of the yarn. When spinning yarns of the same thickness and using mature fibers with finer fineness, the yarn strength is higher due to the large number of fibers contained in the yarn, the large indirect contact surface of the fibers, and the tight cohesion. At the same time, the fine fiber is also suitable for spinning finer yarn. However, the finer the fineness is, the better. Too fine fibers are easy to break and produce neps during processing.

4. Fiber strength. It refers to the maximum load that a fiber or a bunch of fibers can bear when drawing is about to break. Generally, it is expressed in grams or grams/milligrams or pounds/milligrams. The strength of a single fiber varies with species or varieties. Generally, fine staple cotton is between 3.5-5.0 grams. Long staple cotton has a dense fiber structure, and the strength can reach 4.5-6.0 grams.

5. Fiber maturity. The maturity of cotton fiber refers to the degree of thickening of fiber cell wall. The thicker the cell wall is, the higher its maturity is, the more fiber turns, the higher its strength, the stronger its elasticity, the better its color, and the higher the relative yarn quality; Low maturity fiber - all economic properties are poor, but the over mature fiber is also not ideal, the fiber is too thick, and the warp is less, so the yarn strength is not high.

Table 2: Comparison of economic properties and spinnable number of cotton fibers

| Economic properties of cotton fiber |

long-staple cotton |

Fine pile cotton |

| color and lustre |

Milky white |

pure white |

| Length (mm) |

35-45 |

21-33 |

| Fineness (m/piece) |

6500-9000 |

4500-7000 |

| Diameter (microns) |

12-14.5 |

13.5-19 |

| Width (microns) |

14-22 |

18-25 |

| Turn (r/cm) |

100-120 |

50-80 |

| Strength (g) |

4.5-6.0 |

3.5-5.0 |

| Fracture length (km) |

27-40 |

21-25 |

| Spinning number (No.) |

Extra fine 4-10 |

Small and medium 11-30 |

Source: Cotton Growth Law and Cultivation with High Quality, High Yield and High Efficiency, Chen Qien and other editors in chief, China Agricultural Publishing House, 1997, page 187.

(3) Classification, processing and inspection of cotton

1. Classification. According to the different physical forms of cotton, it can be divided into seed cotton and lint cotton. The cotton farmers pick from the cotton tree is called seed cotton, and the cotton after seed cotton processing is called lint cotton. Generally speaking, the cotton yield refers to the lint yield. According to the different processing machinery, cotton is divided into serrated cotton and roller cotton. The lint produced by the zigzag gin is called zigzag cotton; The lint produced by the roller gin is called roller cotton. The production efficiency of roller cotton is low, and the processed cotton has high impurity content, but it has no damage to the cotton fiber, and the fiber is relatively long; The lint processed by saw gin has low impurity content and high working efficiency, but it has certain damage to cotton fiber. At present, fine staple cotton is basically sawtooth cotton, and long staple cotton is generally roller cotton.

2. Processing. Generally, lint percentage is used to represent the proportion of seed cotton processed into lint. In normal years, lint percentage is 36-40, that is, 100 jin seed cotton can produce 36-40 jin lint. The lint cannot be scattered. It must be baled into cotton bales that meet the national standards. There are two types of standard lint package in China: 85kg/package (± 5kg) and 200kg/package (± 10kg), most of which are 85kg.

3. Inspection. The quality inspection of cotton in China is carried out in accordance with the national standard GB1103-1999 for fine staple cotton. According to the standard, cotton inspection is divided into the following indicators:

Grade: cotton is divided into Grade 1 to Grade 7 and substandard cotton according to maturity, color characteristics and rolling quality.

Length: according to the length of cotton fiber, there are length grades. With 1mm as the grade spacing, cotton fiber is divided into seven length grades, 25-31mm.

Makrolon value: Makrolon is transliteration of Micronaire in English. Makrolon value is a comprehensive indicator reflecting cotton fiber fineness and maturity. The larger the value, the thicker the cotton fiber, the higher the maturity. The specific measurement method is to use an air flow meter to measure the air permeability of cotton fiber with constant weight after being pressed into a fixed system, and express it with the scale value. There are three levels of micronaire values, namely A, B and C. Level B is the standard level of micronaire values.

Moisture regain rate: the moisture regain rate of cotton is 8.5%, and the maximum moisture regain rate is 10.5%. In practical work, the moisture regain of raw cotton is generally measured by the electric tester.

Impurity content: the standard impurity content of roller cotton is 2.5%. In practical work, the moisture regain of raw cotton is generally measured with a raw cotton impurity analyzer. Hazardous sundries: it is strictly prohibited to mix hazardous sundries into cotton.

Cotton inspection includes sensory inspection and instrument inspection. At present, China's cotton inspection instruments are mainly used to test some physical indicators of cotton, such as the strength of cotton fiber, the Markron value, and so on. There is no cotton grading instrument that fully conforms to China's national conditions. Therefore, according to the national standard, cotton grading is mainly sensory inspection, supplemented by instrument inspection. In China, the national fiber inspection bureaus (institutes) at all levels are responsible for cotton inspection and arbitration, and the provincial (municipal) commodity inspection bureaus are responsible for cotton import and export inspection. On December 17, 2003, the National Development and Reform Commission, the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, the Ministry of Finance, the All China Federation of Supply and Marketing Cooperation, and the Agricultural Development Bank of China jointly issued the Cotton Quality Inspection System Reform Plan, which clearly stated that the goal of cotton quality inspection reform is to strive for about five years, adopt scientific, unified The cotton inspection technology standard system that is in line with the international standards, implements the authoritative, instrumented and universal inspection in the cotton processing link, and establishes a scientific and authoritative cotton quality inspection system that is consistent with China's national conditions, in line with international practices.

(4) Cotton grading

Cotton grading is an indispensable means to determine cotton quality and measure the use value and market price of cotton in the process of cotton purchase, processing, storage and sales. It can fully and reasonably use resources to meet the needs of production and consumption. Cotton grade is composed of two parts: grade grading and length grading.

1. Grade grading. Generally speaking, cotton grade grading is carried out against the physical standards (standard samples), which is the basis of grading. At the same time, it is assisted by other measures, such as using hand pulling and hand feeling to experience the maturity and strength of cotton, looking at the color characteristics and rolling quality. According to the comprehensive situation of the above indicators, cotton grade is determined. According to the national standard, grade three is the grade standard grade.

2. Length grading. The length grading is carried out by hand pulling ruler. The main body length of cotton is obtained by hand pulling fibers (the length of a group of fibers with the most content in a bundle of fibers), and the length of cotton fibers is obtained by measuring the bundles with a special ruler. All length values are guaranteed length, that is, 25 mm means the cotton fiber length is 25.0-25.9 mm, 26 mm means the cotton fiber length is 26.0-26.9 mm, and so on. At the same time, the national standard also stipulates that 28mm is the length standard level; If the length of Grade V cotton is more than 27mm, it is calculated as 27mm; 6、 The length of Grade 7 cotton is 25 mm. The combination of grade grading and length grading can divide cotton into 33 grades, forming the grade sequence of cotton. If the standard product specified in the national standard is 328, it means that the grade is Grade 3 and the length is 28.0-28.9 mm.

Table 3: Classification of cotton grades

| Grade

Length (mm)

|

class a

|

second level

|

Level 3

|

Level IV

|

Level 5

|

Level 6

|

Level 7

|

| thirty-one |

one hundred and thirty-one |

two hundred and thirty-one |

three hundred and thirty-one |

four hundred and thirty-one |

|

|

|

|

30

|

one hundred and thirty |

two hundred and thirty |

three hundred and thirty |

four hundred and thirty |

|

|

|

|

29

|

one hundred and twenty-nine |

two hundred and twenty-nine |

three hundred and twenty-nine |

four hundred and twenty-nine |

|

|

|

|

28

|

one hundred and twenty-eight |

two hundred and twenty-eight |

three hundred and twenty-eight |

four hundred and twenty-eight |

|

|

|

|

27

|

one hundred and twenty-seven |

two hundred and twenty-seven |

three hundred and twenty-seven |

four hundred and twenty-seven |

five hundred and twenty-seven |

|

|

|

26

|

one hundred and twenty-six |

two hundred and twenty-six |

three hundred and twenty-six |

four hundred and twenty-six |

five hundred and twenty-six |

|

|

|

25

|

one hundred and twenty-five |

two hundred and twenty-five |

three hundred and twenty-five |

four hundred and twenty-five |

five hundred and twenty-five |

six hundred and twenty-five |

seven hundred and twenty-five |

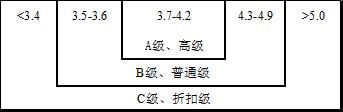

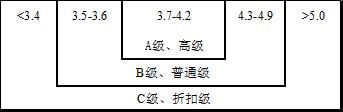

3. Grading of micronaire value. There are three levels of micronaire values, namely A, B and C. Level B is the standard level of micronaire values (see Table 4).

Table 4: Grading range of micronaire value

GB1103-1999 stipulates that 328B fine pile white cotton is the standard grade, that is, it means grade III fine pile white cotton with a length of 28mm and a micronaire value of grade B.

GB1103-1999 stipulates that 328B fine pile white cotton is the standard grade, that is, it means grade III fine pile white cotton with a length of 28mm and a micronaire value of grade B. (5) Cotton storage and storage

Cotton is generally stored in professional cotton storage warehouses. At present, there are two types of domestic cotton storage warehouses: brick concrete warehouse and steel plate warehouse. The storage warehouse requires convenient transportation, fire prevention, ventilation, moisture-proof, mildew proof, especially fire prevention. The cotton storage warehouse is a super fire prevention unit.

Generally speaking, cotton should be stacked in the warehouse, and stored outside the warehouse with tarpaulin. The cushion (sleeper or stone) shall be laid under the cotton stack, and the package shall be placed horizontally when stacking, and the upper and lower layers shall be cross jointed. Necessary passages shall be reserved between stacks. The cotton warehouse area shall be equipped with weather observation louver boxes, and each warehouse shall be equipped with a thermometer and hygrometer. The storekeeper shall check the warehouse every day, measure the temperature and humidity, and make records. According to the weather change and the temperature and humidity difference inside and outside the warehouse, measures such as ventilation and moisture dissipation or closing the warehouse should be taken timely. Generally, the temperature in the warehouse should be kept below 30 ℃, the maximum temperature should not exceed 35 ℃, the relative humidity should not exceed 70%, and the moisture content of cotton in storage should not exceed 10%.

Under normal storage conditions, cotton has a long shelf life. However, due to certain moisture content in cotton, under high temperature conditions, especially when the temperature exceeds 35 ℃, the color may change, resulting in natural variation, which will affect the grade of cotton. According to the analysis of an experienced cotton warehouse keeper, the natural variation of cotton is in the shape of "S", that is, the variation is slow at the beginning, rapid in the middle period, and slow after a certain time. Generally speaking, new cotton that meets the moisture content specified in the national standard (moisture content is not more than 10.5%) is placed in the warehouse under normal storage, and natural variation will not occur before hot summer and high temperature, but after summer, due to temperature rise, humidity increase and other reasons, it may cause natural variation of cotton, which will make new cotton fall by an average of one grade in a cotton year, and the higher the grade, The more stable, the lower the grade, the more unstable the quality, and the more prone to natural variation.