Product Introduction

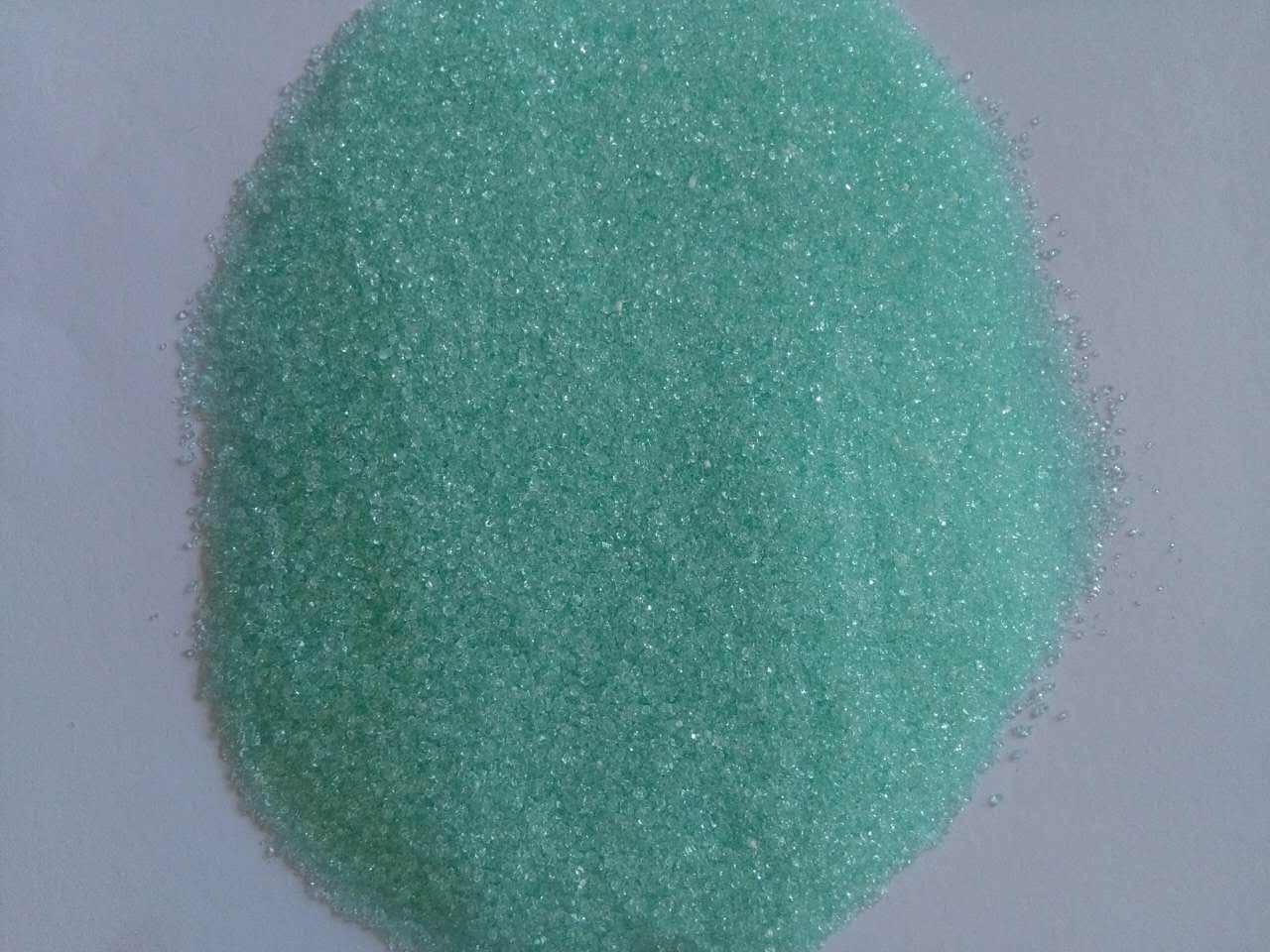

Ferric chloride, chemical formula FeCl3. It is a covalent compound. It is a dark brown crystal with a melting point of 306 ℃ and a boiling point of 316 ℃ [1]. It is easily soluble in water and has strong water absorption. It can absorb water in the air and deliquescence. When FeCl3 precipitates from the aqueous solution, six crystal waters are FeCl3 · 6H2O, and ferric chloride hexahydrate is orange crystal. Ferric chloride is a very important iron salt.

The solid products adopt chlorination method, eutectic mixture reaction method and titanium tetrachloride by-product method, and the liquid products adopt hydrochloric acid method and one-step chlorination method.

Put the ferric acid pickling solution or waste hydrochloric acid in the reactor unit, and add iron powder or iron filings at the same time. The heat generated by the exothermic reaction of acid and iron preheat the materials, then add catalyst and oxygen, and then start the circulating pump to circulate the reaction solution for 3-5 hours until the polymerization reaction is complete; The reaction liquid is transferred to the sedimentation tank for sedimentation or the products are separated and enriched by filtration. The production cost of polymeric ferric chloride is reduced by using ferric acid cleaning solution or waste hydrochloric acid to realize the comprehensive utilization of waste resources. [3]

1. Chlorination method

The waste iron filings and chlorine gas are used as raw materials to react in a vertical reactor. The generated ferric chloride vapor and tail gas are discharged from the top of the furnace and enter the collector to condense into solid crystalline ferric chloride, which is the finished product. The tail gas contains a small amount of unreacted free ferric chloride. Absorb chlorine with ferrous chloride solution to obtain ferric chloride solution as a by-product. During production and operation, the ferric chloride vapor will generate strong heat after contacting with the moisture in the air and release hydrochloric acid gas, so the pipeline and equipment should be well sealed. The whole system operates under negative pressure. [3]

2. Reaction method of eutectic mixture (melting method)

In a reactor with acid resistant lining, iron filings and dry chlorine are allowed to react in the eutectic mixture of ferrous chloride and potassium chloride or sodium chloride (for example, 70% FeCl3 and 30% KCl). As ferric chloride, sublimation is collected in the condensation chamber, and the ferric chloride produced by this method is of high purity. [3]

3. Synthesis method of ferric chloride solution

Dissolve iron filings in hydrochloric acid to form ferrous chloride first, and then lead to chlorine gas to oxidize to ferric chloride.

Cooling the concentrated ferric chloride solution will produce hexahydrate crystal of ferric chloride. [3]

4. Complex decomposition method

The finished product of ferric chloride is obtained by reaction and crystallization of ferric oxide and hydrochloric acid. [3]