LCP

The industrial liquid crystal polymer (LCP for short) was originally developed by DuPont Company in the United States as a solvogenic poly (p-phenylene terephthalamide) (Kevlar ®)。 Because this type of polymer can only be processed in solution and cannot be melted, it can only be used as fiber and coating, and is a special engineering plastic raw material.

1. LCP classification

LCP

2. Common application of LCP

Thermotropic LCP has the structure of all aromatic polyester and copolyester. It also has a densely arranged linear polymer chain structure, and the formed product has good unidirectional mechanical properties. Good high temperature performance (heat deformation temperature is 121~355 ℃), good radiation resistance, hydrolysis resistance, weather resistance, chemical resistance, inherent flame retardancy, low smoke generation, high dimensional stability, low moisture absorption, extremely low linear expansion coefficient, high impact strength and rigidity (compared with steel by the same weight, LCP's strength is greater than steel, but the rigidity is only 15% of steel). LCP can resist acid, solvent, hydrocarbon and other chemicals, and has good barrier property.

3. Development history of LCP

The full name of LCP plastic raw material is LIQUID CRYSTAL POLYMER, and the Chinese name is liquid crystal polymer. It is a new type of polymer material, which generally presents liquid crystal property in the molten state. This kind of material has excellent heat resistance and processing properties. Melt polycondensation is the main polymerization method, and solid phase polycondensation is often supplemented by all aromatic LCP to produce high molecular weight products. Non aromatic LCP plastic materials are usually produced by one-step or two-step melt polymerization. The technology of continuous melt polycondensation to produce high molecular weight LCP has been developed. The tensile strength and bending modulus can exceed the developed thermoplastic engineering plastics. Good mechanical properties, dimensional stability, optical properties, electrical properties, chemical resistance, flame retardancy, processability, good heat resistance, and low coefficient of thermal expansion.

4. LCP business opportunity

-

Supply LCP002

Supply LCP002

-

Supply LCP 52

Supply LCP 52

-

Supply LCP Nippon

Supply LCP Nippon

-

Supply E6807L

Supply E6807L

-

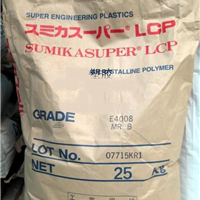

***Original package/LC

***Original package/LC

-

Cash Recovery LCP

Cash Recovery LCP

-

Supply LCP002

Supply LCP002

-

LCP GA13

LCP GA13

-

LCP ceramsite light partition

LCP ceramsite light partition

-

Supply LCP E6

Supply LCP E6