【 Building materials network 】

1 Scope of application

This standard is applicable to underground structural engineering waterproof layer of industrial and civil buildings to SBS , APP and other polymers asphalt Waterproof roll Waterproof layer works paved.

2 Construction preparation

2.1 Materials

SBS, APP high polymer modified asphalt waterproof coiled material is a waterproof coiled material product made of polyester felt or glass fiber felt as the matrix and covered with isolation materials on both sides; Matched with waterproof coiled material Auxiliary materials It must be compatible with the waterproof roll material.

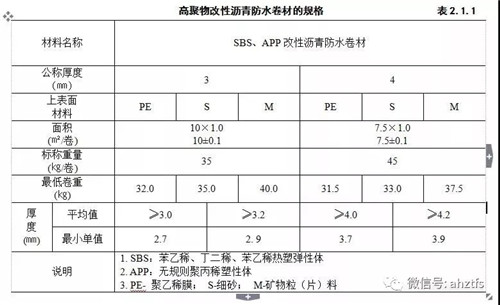

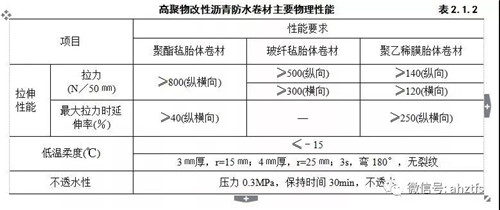

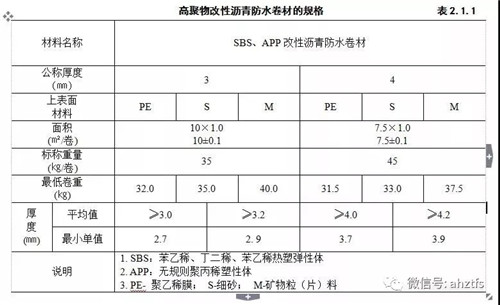

2.1.1 The weight, area and thickness of waterproof coiled material shall meet the provisions and requirements in Table 2.1.1.

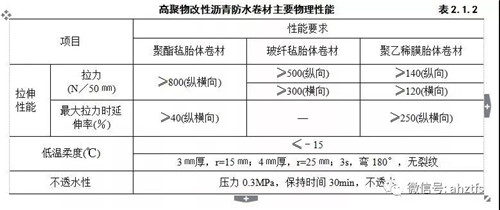

2.1.2 The main physical properties of coiled materials shall meet the provisions and requirements in Table 2.1.2.

2.1.3 Auxiliary materials

Cold primer oil, sealing compound and other supporting materials.

2.2 Machinery and equipment

Rolling brush, dust blower, electric mixer, flame heater (Gasoline injection lamp Or single or multi head LPG heaters), pressure rollers, rubber scrapers, knives, scissors, oil drums or fuel Gas cylinder , flat shovel, broom, steel Tape measure Snap box, brush and shovel.

2.3 Operating conditions

2.3.1 During the construction of underground waterproof works, the ground must be kept be launched The position shall be stable below 500mm of the low waterproof layer of the base zui and maintained until the waterproof layer construction is completed.

2.3.2 The surface of concrete cushion shall be poured, trowelled and polished at the same time. The temporary protective wall used for waterproof roll paving construction should be 1:3 lime mortar Masonry and trowel the leveling layer, which is used for permanent waterproof roll paving construction The waterproof base surface of the protective wall should also be 1:3 cement Mortar plastering, leveling and polishing. If the surface of waterproof base course is not easy to meet the drying requirements, inorganic aluminum salt with 10% cement can be used Waterproof agent Mix waterproof mortar as the leveling layer of waterproof base course to prevent the penetration of underground water.

2.3.3 The internal and external corners of the waterproof layer base course and the pipe root shall be plastered into a circular arc angle (r ≥ 50mm).

2.3.4 The base surface of the waterproof layer shall be firm and dense, free of sand, hollowing, looseness, cracks, etc; It shall be flat and free of pitted surface, concave and convex pits and other defects; Dry (the moisture content is 9%, and the empirical measurement method is to cover a square meter of waterproof coiled material flat on the surface of the base course, stand for 3~4h, and there is no obvious condensation watermark on the side close to the base course).

2.4 Technical preparation

2.4.1 Waterproof materials shall be well packaged and clearly marked (name, manufacturer, production date, product quality validity period, anti-counterfeiting marks, etc.).

2.4.2 The waterproof coiled materials shall be of the same type and grade from the same manufacturer, and 5 rolls shall be taken for more than 1000 rolls, 4 rolls shall be taken for 500~1000 rolls, 3 rolls shall be taken for 100~499 rolls, and 2 rolls shall be taken for less than 100 rolls for specification, size and appearance quality inspection: whether there are cracks, folds, holes, peeling, carcass whitening on the appearance, and whether the whole roll has Connector 。

2.4.3 The base course treatment agent shall be sampled in a batch based on the amount of products entering the site in the same shift, and the quality shall be checked by opening the barrel and stirring evenly: it shall be dispersed in the solution without obvious asphalt silk.

2.4.4 sealing material Take each incoming quantity as a batch for sampling and observation of quality: the appearance is black, even and paste like, without caking and not soaked filler 。

2.4.5 On site sampling and retest: among the coiled materials that pass the spot inspection of appearance quality, take any one roll and cut it 2500mm away from the outer roll head, and then cut two full sheets of coiled materials 800mm long longitudinally (including 1000mm long modified asphalt polyethylene membrane waterproof coiled materials) for physical performance inspection; At least 5 samples shall be taken evenly from the stack of sealing materials that pass the spot inspection appearance quality inspection, and a total of 2 kg of clean equivalent samples shall be taken from each pile for physical property inspection; The project supervisor or the owner's representative shall be present and participate in the witness sampling, which can be used only after the retest report is qualified.

3 Operation process

3.1 Process flow

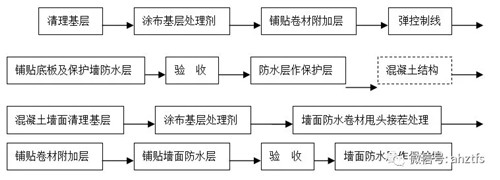

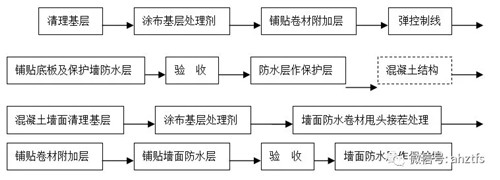

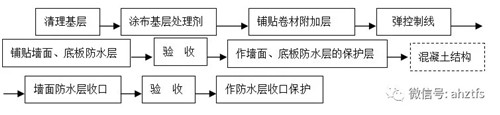

3.1.1 External protection and sticking construction

3.1.2 Construction with external prevention and internal sticking method

3.2 Operation method

3.2.1 Base course cleaning

The mortar lumps, sundries, dust, etc. on the surface of the base course shall be thoroughly removed and cleaned.

3.2.2 Coating base treatment agent

The matched base course treatment agent shall be stirred evenly with a mixer after being opened, and then evenly coated on the base course surface with a roller brush or scraper. The parts that are not easy to roll brush and scrape can be supplemented with an oil brush. The base course treatment agent on the base course surface shall not expose the bottom. Waterproof coiled materials can be paved after being dried for 8h and not sticky by finger contact.

3.2.3 Paving additional layer of waterproof coiled material

Before paving the large waterproof coiled material, all the internal and external corners, pipe roots, post cast strips and special parts required by the design on the waterproof base surface shall be paved with an additional layer of waterproof coiled material. The width of the additional layer coiled material shall be no less than 500 mm at the internal and external corners, and the pipe root shall be no less than the pipe diameter plus 300 mm and divided equally at the corners. 300 mm shall be added on each side of the post cast strip and deformation joint, The specific paving method is that the full adhesion paving method shall be adopted for the internal and external corners and pipe roots, and the empty paving method shall be adopted for the horizontal surface of the post cast strip and deformation joint. If the design has specific requirements, the design requirements shall prevail.

3.2.4 Snap control line

According to the specification and size of the waterproof roll and the requirements of the overlapping part, pop up the waterproof roll paving quality control reference line with an obvious pink wire box.

3.2.4.1 At the corner between the facade and the plane, the lap position of coiled material shall be set on the horizontal plane and not less than 600mm away from the facade.

3.2.4.2 The lap width of the long side and short side of waterproof coiled material should not be less than 100mm.

3.2.4.3 When the coiled material waterproof layer is paved in double layers or above, the overlapping joints of the adjacent waterproof coiled materials on the upper and lower layers shall be staggered by 1/3~1/2 width, and the upper and lower layers of coiled materials shall not be paved vertically.

3.2.5 Waterproof roll paving method

The waterproof coiled material and the base layer at the base plate base plane and the temporary protective wall surface should be laid in the empty way, and the point and strip bonding methods should be used. The full bonding method should be used between the upper and lower waterproof coiled materials, between the waterproof coiled material and the permanent protective wall surface, and between the waterproof coiled material and the upstream surface of the external wall of the concrete structure.

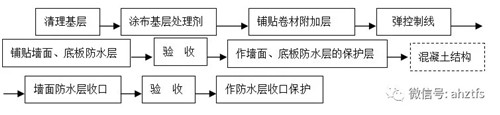

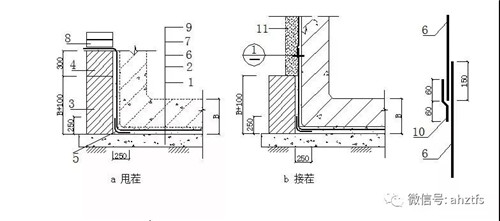

3.2.5.1 External protection and sticking method

(1) The waterproof coiled material shall be paved with additional layers first, then with horizontal surface, and then with facade.

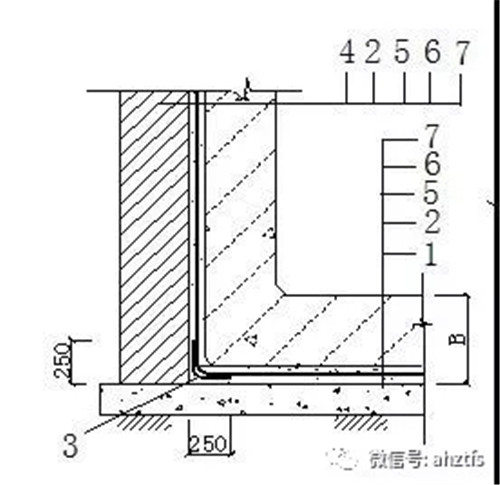

(2) See Figure 3.2.5.1 for the structure of coiled material waterproof layer

(3) For the waterproof roll head part that turns from the floor plane to the facade protection wall surface, measures such as laying two temporary protective brick walls to press the weight shall be taken while covering the soft protective layer on the waterproof roll head surface to prevent the waterproof roll from sliding down.

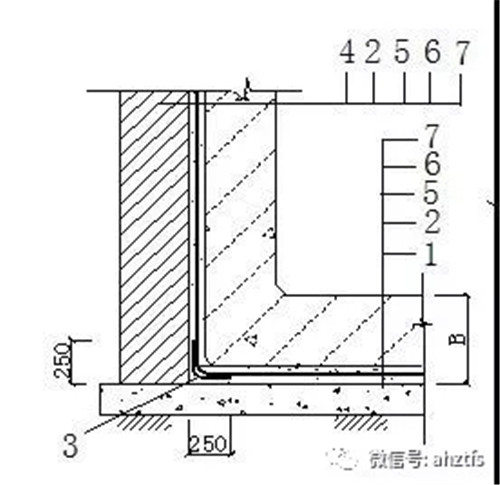

3.2.5.2 External protection and internal sticking method

(1) The waterproof coiled material shall be paved with additional layers first, then the large surface of the facade, and then the horizontal surface.

(2) See Figure 3.2.5.2 for the structure of coiled material waterproof layer

3.2.5.3 Key points of waterproof membrane paving

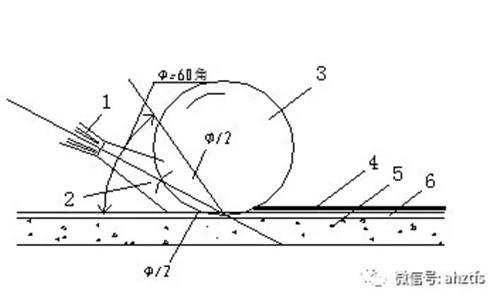

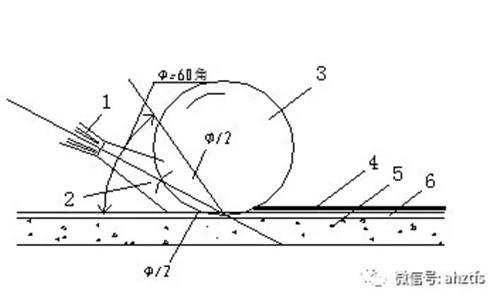

(1) Full adhesion paving method: according to the control reference line of coiled material paving, first spread the waterproof coiled material on the predetermined position, roll up 1/2 section of the coiled material's length after adjustment, and align the angle between the coiled material and the bonding surface of the base layer with a flame heater (see Figure 3.2.5.3), so that the nozzle of the flame heater is about 350mm away from the coiled material surface, Evenly heat until the hot melt adhesive on the surface of the coiled material begins to melt (the adhesive surface is black and bright), then slowly roll forward to pave the coiled material while heating. The lap joint of the coiled material should be squeezed out of the hot melt adhesive and then scraped flat. After the paving of this section of coiled material is completed, another section of coiled material should be paved with the same hot melt, and each adjacent coiled material should be paved accordingly.

Figure 3.2.5.1 Waterproof structure of external protection and external sticking method

1 - Concrete cushion; 2 - Mortar leveling layer; 3 - Permanent Sexual protective wall; 4 - Temporary protective wall; 5 - Additional layer of coiled material; 6 - Waterproof layer of coiled material; 7 - Protective layer of waterproof layer; 8 - Waterproof coiled material head swing protection; 9 - Concrete structure; 10 Waterproof coiled material cover strip; 11 - Protective layer of waterproof layer

Figure 3.2.5.2 Waterproof Structure Diagram of External Waterproofing and Internal Sticking Method

1 - Concrete cushion; 2 - Mortar leveling layer;

3 - Additional layer of coiled material; 4 - Permanent protective wall;

5 - Waterproof layer of coiled material; 6 - Protective layer of waterproof layer;

7 - Concrete structure

Figure 3.2.5.3 Hot melt flame, coiled material and base course

Relative position of surface

1 - Nozzle; 2-flame; 3 - Waterproof coiled materials in rolls;

4 - Waterproof layer of coiled material; 5 - Concrete cushion;

6 - Cement mortar leveling layer

(2) Empty laying method: according to the control datum line of coiled material laying, the waterproof coiled material is first spread and laid at the predetermined position. After adjustment, each overlapping edge of the adjacent coiled material is raised separately, and the flame heater is used to align the overlapping surface of the coiled material to evenly heat and bake until the hot melt adhesive on the surface of the coiled material begins to melt (the adhesive surface is black and bright), then all the overlapping surfaces of the coiled material can be bonded, Hot melt adhesive overflows from the lap joint of coiled material and is scraped immediately.

(3) Point sticking paving method: the bonding point between each sheet of coiled material and the surface of the base course is 150 × 150mm, with a spacing of 1000mm. The adjacent lap joints must be fully pasted together. See the full sticking paving method and empty paving method for the key operation points.

(4) Strip bonding and paving method: each sheet of coiled material shall be bonded with at least two strips in the long direction and the base course surface, and the strip width shall be 150mm. The lap joints of adjacent coiled materials must be fully bonded together. Refer to the full bonding and empty paving methods for the key operation points.

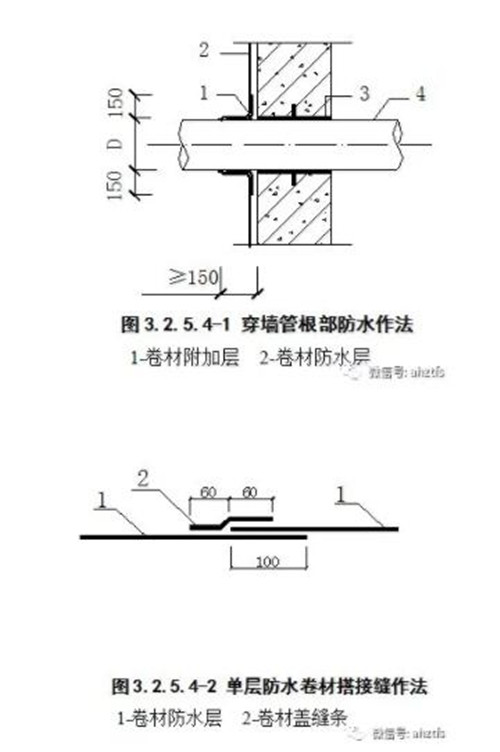

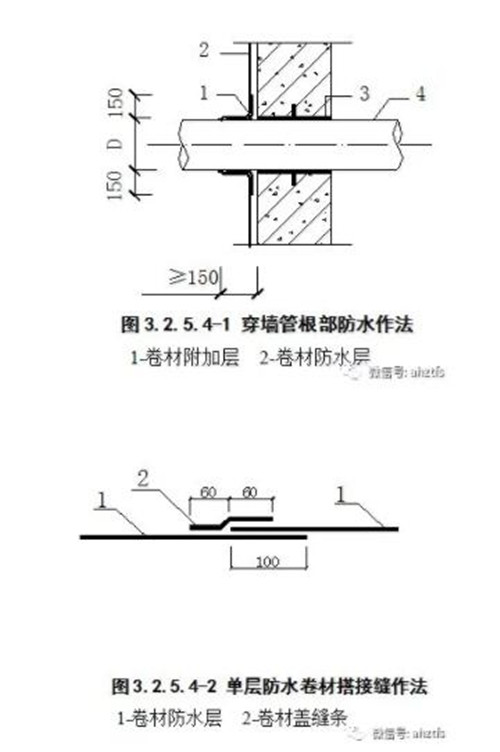

3.2.5.4 Detailed practice

(1) The hot-melt wrapping of coiled material at the root of the through wall pipe shall be wrapped layer by layer with the large waterproof coiled material, and the upper end of each layer of coiled material shall cover the lower end, as shown in Figure 3.2.5.4-1.

(2) When the waterproof layer of coiled material is single-layer waterproof, reinforcement treatment shall be carried out at the lap joint. The main method is to take the lap joint as the center line, and apply a 120mm wide waterproof coiled material seam covering strip by hot melting across the lap joint, as shown in Figure 3.2.5.4-2.

(3) Before lapping the head of waterproof coiled material on the outer wall, the temporary protective wall shall be removed first, the mortar and sundries on the head of coiled material shall be cleaned, and then the head of coiled material shall be pasted on the structural wall. When lapping, the head of coiled material shall be lapped along the water for 150 mm with no damage on the surface of the head of coiled material, and the lap joint of coiled material shall be fully pasted with seam covering strips. See Fig. 3.2.5.1 ① for the practice. If the coiled materials of double layers and above are overlapped, the overlapping parts of each layer of coiled materials shall be staggered with each other, not less than 150 mm, and the waterproof coiled material covering joint strip shall be set on the surface coiled material overlapping joint.

3.3 Seasonal construction

The construction of underground waterproof layer is strictly prohibited to be arranged in rainy days, snowy days and Class V and above windy days, and the ambient temperature for construction shall not be lower than - 10 ℃.

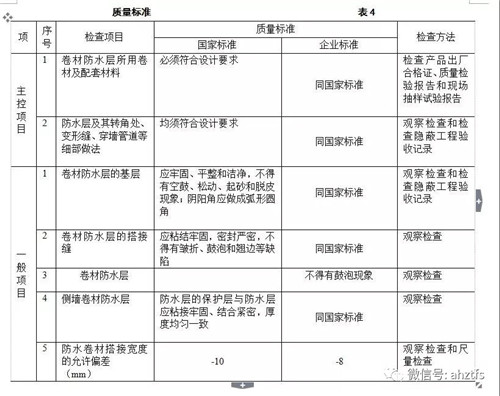

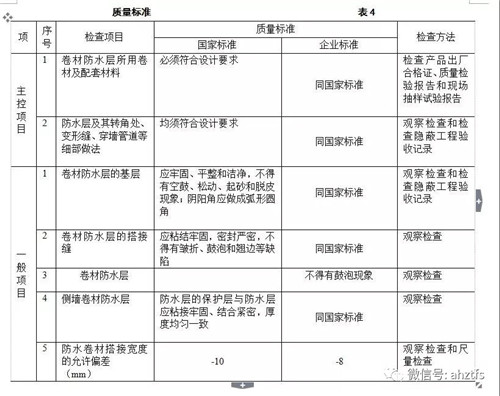

4 Quality standards

The engineering quality standard of underground waterproof layer shall comply with the provisions and requirements in Table 4

5 Finished product protection

5.1 During waterproof construction: it is forbidden to throw materials and tools into the foundation pit; All construction and inspection and acceptance personnel at all levels entering the waterproof working surface shall not wear spiked shoes, and personnel irrelevant to construction and inspection and acceptance shall not enter the unprotected waterproof layer.

5.2 It is strictly prohibited to chisel holes or holes on the completed waterproof layer. If it is necessary to chisel due to design changes and construction, the procedures must be performed according to the specified procedures and a repair plan must be formulated. The chiseling and timely repair can be carried out only after the approval of the project technical director.

5.3 Temporary stubble rejection of facade waterproof coiled material shall be provided with fixed protection measures to prevent fracture and damage.

5.4 After the waterproof coiled material is paved, it shall be concealed and accepted in time and the protective layer shall be made. When pouring the protective layer of fine aggregate concrete, the driving line for horizontal transportation of fine aggregate concrete on the bottom plate shall be paved with a packway, the iron leg root of the trolley must be wrapped with rubber skin, and the concrete cannot be poured directly on the waterproof layer.

5.5 For the external wall waterproof layer constructed by the external waterproofing and sticking method, when building the brick protective wall, the gap between the protective wall and the waterproof layer shall be filled with mortar along with the masonry.

5.6 A special person must be assigned to monitor the waterproof layer during the whole process of the immediate operation of the waterproof layer.

6 Quality problems to be noticed

6.1 Void of coiled material waterproof layer

6.1.1 Cause analysis: hollowing mostly occurs between the waterproof base course and waterproof coiled material at the full adhesive paving part. The main reasons are that the water content of the waterproof base course is too high, the surface of the base course is not dry, and the waterproof coiled material is not densely paved. In addition, the surface of the coiled material is black and easy to absorb heat, which causes the moisture in the base course to be heated and converted into expansion gas, which causes the coiled material to peel off the base course and form bubbles. The external force generated when pouring concrete or backfill soil, The air drum part of the coiled material waterproof layer is squeezed, forming a potential leakage hazard.

6.1.2 Control and prevention measures: ensure the drying time of waterproof base course and make the moisture content of base course surface meet the requirements; When the base course surface is wet and cannot meet the drying requirements, wet interface agent shall be painted on the wet base course surface; When paving the waterproof coiled material, the air shall be discharged with rolling to ensure that the waterproof coiled material is firmly bonded with the base course; Shorten the exposure time of the waterproof layer, and avoid sun exposure and rain soaking the waterproof layer.

6.2 Leakage of waterproof layer

6.2.1 Cause analysis: most of the leakage occurs at the first horizontal joint of the concrete outer wall root, the post cast strip of the bottom plate, and the pipe penetration. The main reason is that the waterproof coiled material is folded from the bottom plate surface to the facade (external protection and external sticking method) and the butt joint is not well handled; The waterproof layer of the coiled material of the post cast strip is easy to be punctured by sundries, and it is not easy to find and completely repair because there is much laitance left in the concrete vibration on both sides of the post cast strip; The root of the pipe is not tightly wrapped.

6.2.2 Control and prevention measures: the waterproof head of coiled material shall be protected to prevent damage. When the waterproof layer is lapped, the effective bonding width of the lapping surface must be ensured, and the joints must be tight; Before pouring concrete at the post pouring belt, it shall be covered effectively. When pouring concrete, it shall be thoroughly cleaned. If any damage is found, it shall be repaired in time; The coil end at the root of the pipe shall be fixed with No. 14 lead wire or hoop, and then sealed with sealing material compatible with the coil.

7 Quality records

7.1 Factory certificate, quality inspection report and on-site sampling (including witness sampling) retest report of waterproof materials.

7.2 Construction inspection records and handover inspection records.

7.3 Acceptance records of concealed works.

7.4 Inspection lot quality acceptance records.

7.5 Quality acceptance records of subdivisional works.

8 Safety and environmental protection measures

8.1 Requirements for safe operation

8.1.1 Waterproof materials, supporting auxiliary materials and fuels shall be stored separately and kept at a safe distance, managed by a specially assigned person, and the distribution shall adhere to the receiving registration system. Waterproof coiled materials shall be placed vertically in a single layer, and large gasoline drums and gas cylinders must be stored separately in the warehouse.

8.1.2 The material stacking place, warehouse and waterproof operation area must be equipped with fire-fighting equipment.

8.1.3 The construction workers must work with certificates and wear protective equipment (masks, work clothes, work shoes, gloves, safety helmets, etc.). They must operate according to the regulations and not violate the rules.

8.1.4 The waterproof operation area must be well ventilated.

8.1.5 Safe and reliable scaffolds must be provided for work at heights, and scaffold boards must be fully paved. Operators must fasten safety belts.

8.1.6 The construction fire must be applied for and can only be used when the site fire permit is obtained.

8.1.7 The flame heater must be operated by specially assigned person and maintained regularly. It is forbidden to use it with fault. The fire must be turned off when refueling and replacing the gas cylinder. It is forbidden to operate on the waterproof layer. When the nozzle is ignited, it is not allowed to face people and keep away from oil drums, gas cylinders, waterproof materials and other flammable and explosive materials.

8.2 Environmental protection measures

8.2.1 After the base course treatment agent and supporting materials enter the site, benzene diluents and solvents shall not be added. During site construction, they shall be used immediately after unpacking and shall not pollute the working surface of non waterproof layer.

8.2.2 Waste waterproof coiled materials, base treatment agents, sealants, fuels and other materials shall be collected and disposed properly.

8.2.3 The cleaning of on-site machines and tools shall not pollute the ground, and liquid leakage collection measures shall be taken for reuse.

![Why do we need [15] standard painting processes?! Why do we need [15] standard painting processes?!](http://img3.bmlink.com//news/2024/4/2/17/638476751123251860.jpg)