|

① |

|

② |

|

Figure ③: Mercedes Benz's high-speed railway in China.

People's vision |

|

④ |

|

Figure ⑤: The railway "battle of a thousand people" in the period of Li Shangkui.

Information picture |

|

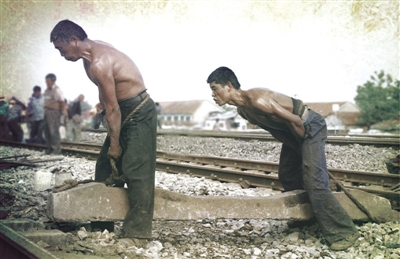

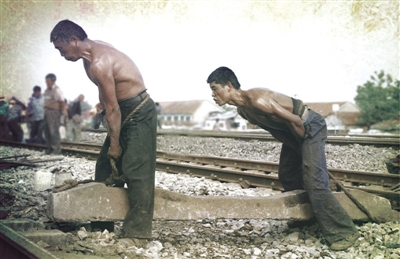

Picture ⑥: Overhaul workers replaced rails during Li Shangkui's period.

Information picture |

Editor's note: When you go on vacation, the high-speed railway is like a dragon running across the vast land. Have you ever thought that behind the scenery along the way through mountains and mountains and the amazing "Chinese speed" in the world, there is also a group of railway maintenance workers who are silently dedicated. They may hide out of the public's view, but they have never been absent from the high-speed development of China's railways. Li Shangkui, Li Zhen and Li Gang have worked on their own posts for 40 years, from pickaxes and rakes to continuous walking tampers.

A few days ago, Li Gang, 31, of Jinan Public Works Machinery Section, near Jinan East Station of Jinan Qingdao High speed Railway Hub Project, was operating a large turnout tamping car to complete line maintenance (Figures ① and ②, photographed by Wang Yujian). The purpose of the line tamping operation is to make the ballast laid under the rail and sleeper evenly and densely distributed, so as to ensure the smooth operation of the train.

Interestingly, just a short time ago, Li Shangkui, Li Gang's grandfather, came to the construction site trembling from his hometown Zaozhuang to see his grandson's work. The 86 year old man was shocked by the roaring yellow locomotive and its extremely high work efficiency. "One era is like another. Today is really an eye opener!"

Coincidentally, three generations of their ancestors and grandchildren were all "craftsmen" in the overhaul of railway lines.

In 1952, Grandpa Li Shangkui became a member of the lineman. The "four big pieces" consisting of "pick, rake, fork and shovel" are the necessary tools for line workers. At that time, all the work was done manually.

"The line is full of people, and you can't see the end at a glance. In dog days, hundreds of kilograms of steel rails are shouldered and pulled by hand, and you will work all day long. If you faint from heatstroke, you will carry them to the side to rest for a while, and then get up to work." Li Shangkui recalled.

In his son Li Zhen's mind (Fig. ④, data picture), what impressed him most was his father's calloused hands. The manual tamping of 1km every day has taken a long time, and even the palm of the hand is callous. In this way, Li Shangkui has been working for 35 years.

Li Shangkui often said, "Be a real person and work steadily.". In 1982, Li Zhen joined the railway recruitment, and his father became a member of the overhaul team of Jinan Railway Bureau.

In the early 1980s, small hydraulic tamping machines and tamping rods began to be popularized, and the operating efficiency was greatly improved. Overhaul construction moved from "slash and burn" to semi mechanized mode.

"At that time, the railway workers were all 'ferocious Zhang Fei'. They talked by shouting. When using the tamping stick, the noise was very loud, and they could not hear other sounds around." Li Zhen said that his voice was the most tired after a day.

In 1994, Jinan Bureau began to equip 08-32 tamping trucks, which can automatically level, track and tamp. With its arrival, pickaxes, tamping sticks and small machines were completely free. The first time I saw the tamper truck, Li Zhen was so happy that he didn't sleep all night. He and his colleagues applied to the captain to go to sleep in the truck.

"Seeing and touching this big guy is happier than buying a new car at home." Li Zhen said that it used to take thousands of people to work continuously for a month. Using a large tamping truck, dozens of people could easily complete it in less than a week.

"The operating conditions at that time were much worse than today. The abandoned green leather carriages were our camping cars for field operations. In winter, the water pipes were frozen inside and outside, and there was no water. Digging a hole nearby and pulling a shed were temporary toilets," said Li Zhen.

Mechanized construction has greatly improved the quality of the line and made the train run more smoothly. From 1997 to 2007, China's railway has experienced six "big speed increases", from an average speed of 50 to 60 kilometers per hour to 200 kilometers for the main trunk line. Behind the "big speed increase", large-scale road maintenance machinery is indispensable.

At the beginning of 2013, large-scale road maintenance machinery welcomed "new members". The DWL-48 continuous walking tamping and stabilizing vehicle, which is independently manufactured in China, can easily realize continuous three pillow tamping operation, and perform dynamic stability at the same time. It can accurately control the line error to 0.1mm. It is the "line massage master" with the highest operating accuracy and efficiency in the world today.

Li Gang, who started work in August of the same year, is also growing rapidly with the upgrading of mechanized equipment. The newly established third turnout team has many young people and is short of manpower. At the age of 26, he was pushed forward. He stepped on position 3 first, and in a few months, he adjusted to the most important position 1 to be responsible for the tamping operation of large machine turnout. Li Gang was not good at words, but he did a good job. "The burden on our shoulders is heavier. Every pick we step on is related to railway safety and is our responsibility."

Li Gang still clearly remembers the unforgettable Mid Autumn Festival he spent on the construction site in the year when the Qingrong Intercity Railway was opened to traffic. At that time, they had been working for 24 hours on a six story railway bridge. Looking at the bright moon of the Mid Autumn Festival, he dialed the phone at home, feeling lost. Father comforted him on the other end of the phone: "Be content with yourself. How many people want to do this job, but they can't do it! You should be worthy of this trust."

From pickaxes and rakes to advanced continuous walking tamping trucks, three generations of overhaul personnel have composed tenacity and delicacy in the ordinary, playing the strong voice of craftsman spirit in every inch.

People's Daily (November 17, 2018, edition 08)

(Editor in charge: Ma Chang, Yuan Bo)

Share to let more people see