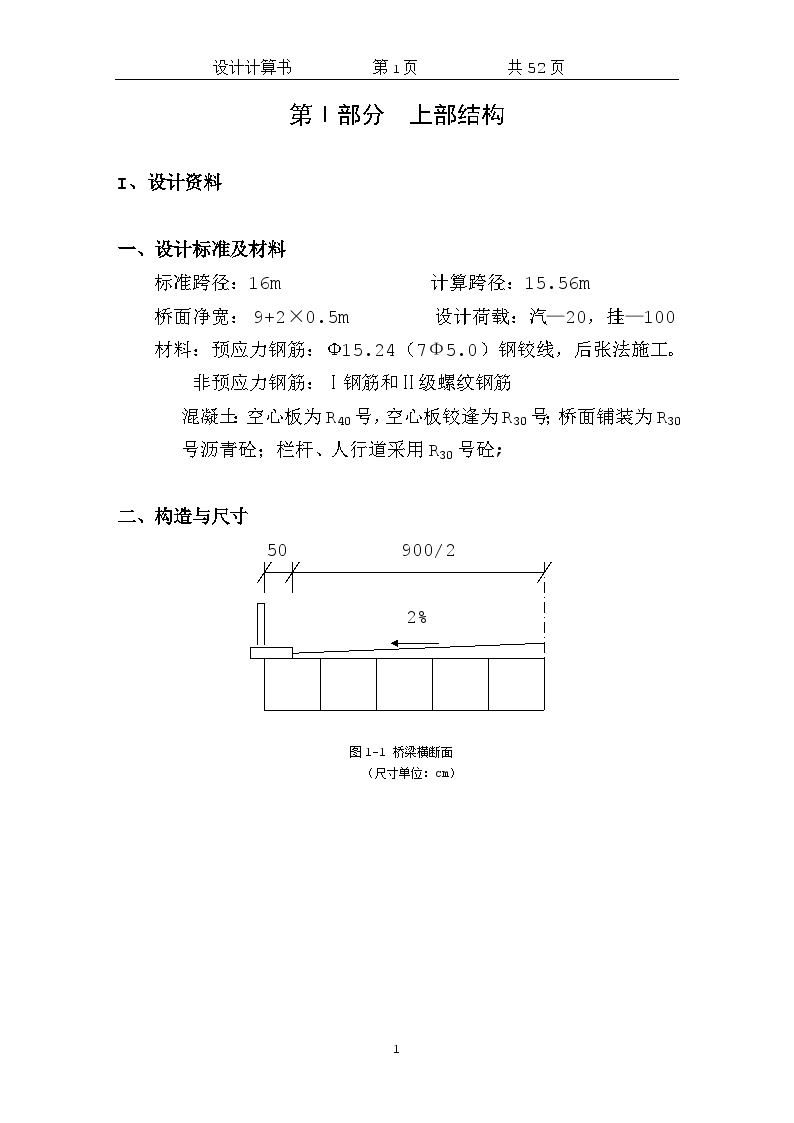

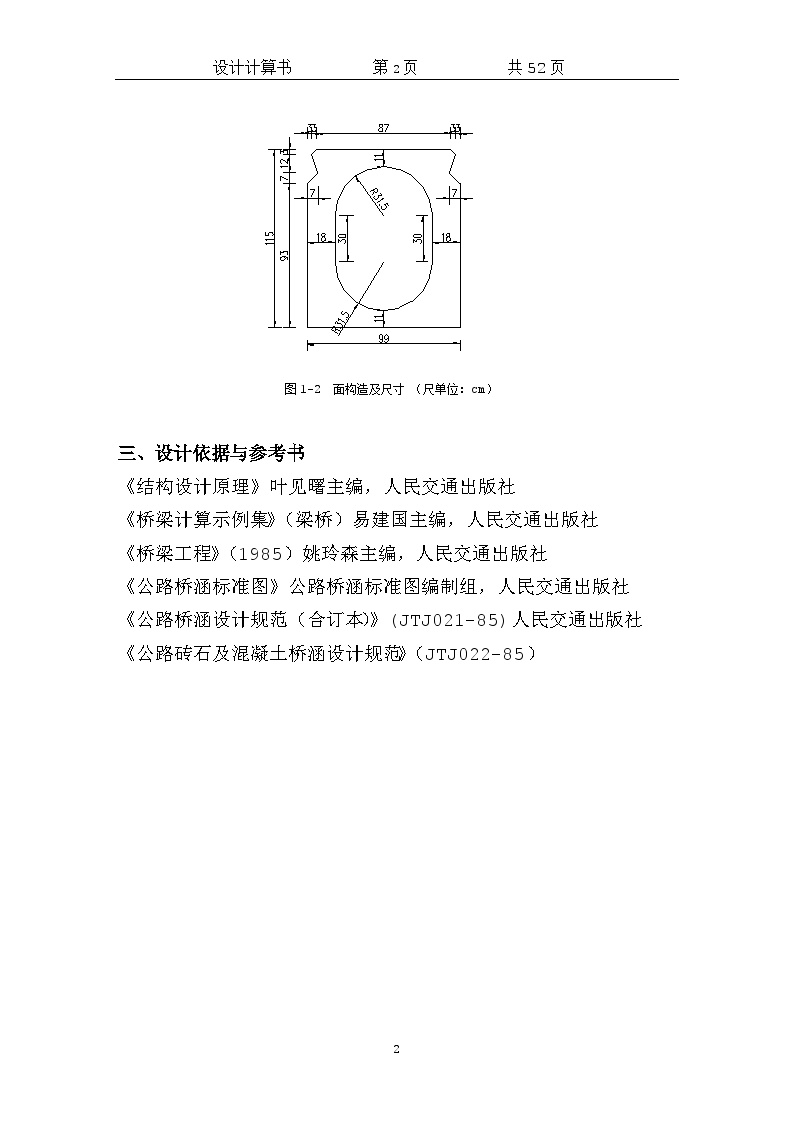

In this drawing, the standard spans are 10m, 13m, 16m and 20m. General drawing of pretensioned prestressed concrete hollow slab. I. Description of superstructure of prestressed concrete hollow slab (L=10, 13, 16, 20m, a=0~45 °) Quantity table of main materials for L=10m hollow slab and one hole superstructure, cross-section drawing of superstructure, general structural drawing of precast slab, layout drawing of middle slab reinforcement, quantity table of middle slab materials, layout drawing of side slab reinforcement, quantity table of side slab materials, layout drawing of cast-in-situ layer reinforcement of bridge deck, layout drawing of obtuse angle reinforcement of inclined slab deck, structural drawing of embedded steel plate of support Quantity table of main materials for one hole superstructure of L=13m hollow slab, cross-section drawing of superstructure, general structural drawing of precast slab, layout drawing of middle slab reinforcement, quantity table of middle slab materials, layout drawing of side slab reinforcement, quantity table of side slab materials, layout drawing of cast-in-situ layer reinforcement of bridge deck, layout drawing of obtuse angle reinforcement of inclined slab deck, structural drawing of embedded steel plate of support Quantity table of main materials for upper structure of one hole of L=16m hollow slab, cross-section drawing of upper structure, general structural drawing of precast slab, layout drawing of reinforcement for medium slab, quantity table of material for medium slab, layout drawing of reinforcement for side slab, quantity table of material for side slab, layout drawing of reinforcement for cast-in-situ layer of bridge deck, layout drawing of reinforcement for obtuse angle slab of inclined slab, structural drawing of embedded steel plate of support Quantity table of main materials for one hole superstructure of L=20m hollow slab, cross-section drawing of superstructure, general structural drawing of precast slab, layout drawing of middle slab reinforcement, quantity table of middle slab materials, layout drawing of side slab reinforcement, quantity table of slab materials, layout drawing of cast-in-situ layer reinforcement of bridge deck, layout drawing of obtuse angle reinforcement of inclined slab deck, structural drawing of embedded steel plate of support II Description of substructure drawing of prestressed concrete hollow slab (pier L=10, 13, 16, 20m, a=0 °~ 45 °), general structural drawing of pile column pier (a=0 °~ 45 °), structural drawing of pier cap reinforcement (L=10m; a=0 °~ 45 °), quantity table of pier cap materials (L=10m; a=0 °~ 45 °), structural drawing of pier cap reinforcement (L=13m; a=0 °~ 45 °); A=0 °~ 45 °) Pier Cap Material Quantity Table (L=13m; a=0 °~ 45 °) Pier Cap Reinforcement Structural Drawing (L=16m; a=0 °~ 45 °) Pier Cap Material Quantity Table (L=16m; a=0 °~ 45 °) Pier Cap Reinforcement Structural Drawing (L=20m; a=0 °~ 45 °) Pier Cap Material Quantity Table (L=20m; a=0 °~ 45 °); A=0 °~ 45 °) Structural drawing of pier anchor bolt III Structural drawing of lower part of prestressed concrete hollow slab (abutment L=10, 13, 16, 20m, a=0 °~ 45 °) Description General structural drawing of pile column abutment (a=0 °~ 45 °) Structural drawing of abutment cap reinforcement (L=10m; a=0 °~ 45 °)