Commencement Report of Reinforced Concrete Circular Pipe Culvert

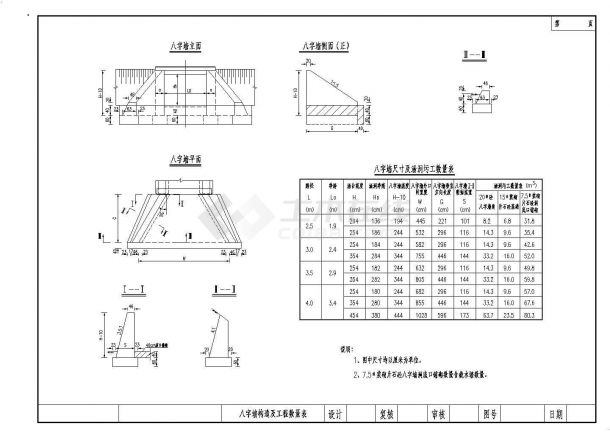

EKXX (1 - φ 1.5m) circular pipe culvert, with a length of 41.72m, an intersection angle of 90 ° with the route, and a maximum filling height of 8.42m at the culvert top, The water inlet and outlet are in the form of splayed wall, and the culvert is under normal construction. The main quantities are shown in the following table: VI. The construction process block diagram of the construction process is shown in Figure 1 below. Surveying and setting out, foundation pit excavation (1), and the total station is used to accurately set out the center pile, side pile, and vertical and horizontal axis of the culvert. Before the excavation of the foundation pit, control piles should be set on the vertical and horizontal axis, and outside the side pile of the foundation pit, Two control pile protection points shall be provided on each side for checking and setting out at any time during construction. The ground elevation shall be measured before the excavation of foundation pit, and the excavation depth shall be controlled according to the designed base elevation. (2) The excavation of foundation pit shall be carried out by excavator and dump truck with the assistance of manual trench cleaning. The excavation of foundation pit shall be carried out continuously to avoid drying the trench. A distance of 20~30cm shall be reserved from the bottom of the foundation pit for one excavation. The excavation shall be manually cleared to the elevation before trench inspection to ensure that the top surface of the foundation pit is solid and undisturbed, and the spoil shall be transported to the spoil ground. (3) The slope of the excavation slope is 1:1.5. The perimeter of the foundation pit shall be expanded by 50cm. The slope shall be manually trimmed into a ladder shape. After leveling, check whether the plane size, position and elevation of the foundation pit conform to the drawing design, and quickly tamp the base and slope. (4) . Drainage should be done around the top of the foundation pit to intercept the surface water to prevent rainwater from washing away the pit wall. Drainage ditches should be set at the lower opening of the foundation pit and drainage methods should be used in the sump. The bottom of the sump should be 50-100cm higher than the bottom of the foundation pit. Electric submersible pumps can be used to pump water to reduce the groundwater level and keep the foundation free of water. (5) After the foundation pit is excavated and treated, immediately notify the laboratory to test the bearing capacity of the foundation base (≥ 250Kpa), and notify the quality inspection department and the supervising engineer for inspection. After the acceptance is qualified, the next process can be started. If the base bearing capacity cannot meet the design requirements, report to the supervising engineer, the owner and the design unit, and take measures to deal with it.