Chinese Foundry Hometown Botou

Botou casting is one of the famous non-material cultures in China. It has a long history, which can be traced back to more than 1300 years with written records. It is one of the birthplaces of China's modern industry. Botou casting has developed with three stages of agricultural civilization, industrial civilization and modern industrial civilization. Botou was originally Jiaohe County. According to the written records, because of the frequent floods in Jiaohe, farmers made a living by smelting iron, and even reached Brunei in the South. This is an earlier record in the historical materials of the Ming and Qing Dynasties, but it is not the earliest history of Botou casting, but the fact that casting has become a production industry. It is difficult to determine when Botou casting first originated. In the farming society, Botou casting is mainly based on agricultural production tools, but also has a large number of daily necessities and weapons, including many handicrafts. The farming period was very long. Botou Foundry produced farming tools, daily necessities, artworks and weapons during this period, and developed slowly. After the modern industrial revolution, during the period of the Republic of China, there were more than 200 pig iron plants in Botou, with four or five thousand workers and a capital of more than three million yuan. Almost all provinces in China had iron plants held by Botou people. For example, Zhang Zhidong founded the Hanyang Iron Factory. As a Cangzhou native, Zhang Zhidong could not be ignorant of Botou casting. He has many northern staff around him. The establishment of an arsenal and an iron factory cannot be separated from casting technology. Although we do not have much information at present, we can speculate that there must be Botou casters there. At the stage of opening the iron plant, Botou Foundry has not only simply served the production of agricultural civilization, but also made immortal contributions to the development of national industry and the prosperity of the people. After the founding of New China, Botou Foundry entered the stage of machinery industry. A large number of agricultural machinery and equipment such as water pumps and waterwheels were manufactured. At one time, the number of people casting in Botou reached more than 80000. The Ministry of Agricultural Machinery of the People's Republic of China named Botou plowshares as historical famous brand products, with an annual production of several hundred thousand pieces. When Handan Xingtai Iron and Steel Base was launched, Botou undertook 299 kinds of 190000 matching technologies, 1800mm large-diameter valves, large coking furnace door frames, large casting plates and 2000kW motors, which are the gold projects never seen in Botou's casting history. At that time, Vice Premier Li Xiannian visited Botou twice. Botou Foundry has entered the modern production industry of production machinery and equipment, instruments, general machinery, auto parts, etc. Botou Foundry has entered the spring of development since the country implemented the "reform and opening up" policy. Especially in the past 20 years, the automobile mold industry derived from the traditional casting industry has developed rapidly. Botou automobile mold industry has become an industry team with high popularity and the most obvious cluster effect in China, no matter in terms of overall scale, R&D capability, or market space and development speed. Botou now has 28 automobile mold enterprises, accounting for 25% of the total number of automobile mold enterprises in China. At present, the city is mainly engaged in the production of mid-range automobile molds, which can be used for medium and light pickup trucks SUV、 Auto manufacturers such as bread manufacturers can provide stamping dies for vehicle panels, and also provide inner liner dies for cars. It has maintained good business relations with more than 40 well-known automobile manufacturers, such as FAW Group, Jiangxi Isuzu, Hafei Automobile, Guangzhou Honda, Japan Honda, and has a high market reputation.

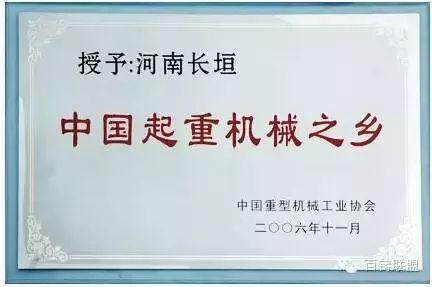

Changyuan, the hometown of cranes in China

Changyuan, the hometown of cranes in China

Changyuan, the hometown of cranes in China Changyuan County is located in the northeast of Henan Province, under the jurisdiction of Xinxiang City. Such an unknown small county has no rich mineral resources, no steel enterprises, no scientific research support around it, and no industrial drive from big cities. However, these adverse conditions have not affected the county to become the leader of the crane industry in China. The sales of small and medium-sized cranes account for more than half of the national market share, and are also exported to neighboring countries. Changyuan County's achievements today are inseparable from the correct leadership and decision-making of the local government. The year 2003 was a turning point for the development of the crane industry in Changyuan County, when the crane industrial park was opened. Today, the park has become an important carrier of the lifting industry in the county. The park has become an advanced gathering area of the domestic lifting industry, a pilot area for scientific and technological innovation, and a new livable and entrepreneurial urban area in Changyuan. In 2009, the industrial sales of Changyuan County reached 17.4 billion yuan, significantly improving the industrial competitiveness. It has successfully attracted 40 enterprises to implement strategic restructuring strategy. In December of the same year, the seminar on frequency conversion technology solutions for the lifting machinery industry of Xinxiang Changyuan was held jointly by Rockwell Automation, a leading supplier of automation control, transmission system products and solutions, and China Automation Network. Mr. Yu Chunlei, Director of Changyuan Industry Bureau, Mr. Zhao Qinglin, Executive Vice President of Changyuan Lifting Industry Association, and Mr. Fu Qiangbing, Section Chief attended the event and delivered enthusiastic speeches, expecting Rockwell Automation to further promote the automation level of Changyuan lifting machinery industry. Changyuan lifting equipment manufacturing industry has initially formed an industrial system with complete categories, wide market coverage and relatively centralized layout, and has become a pillar industry with rapid growth. Nowadays, Changyuan Hoisting Industrial Park is the largest and most complete trading center of hoisting machinery and accessories in China. Now, there are 221 enterprises in Changyuan Crane Industrial Park, more than 900 merchants, with an annual output of 600000 sets. The key to such achievements lies in the correct decision of the government leaders in the early stage, actively leading people to embark on a characteristic road of prosperity. In the future, the county will highlight the development direction of "high-end", "high-tech" and "high-quality", and adhere to independent innovation, Make Changyuan crane industry stand at the top of the world.

Yongjia, the hometown of pumps and valves in China

In April 2004, Yongjia County in Wenzhou, Zhejiang Province was awarded the title of "Home of Pumps and Valves in China" by the China Industry Association. Yongjia County deserves this reputation. The total output value of pumps and valves in this county has reached more than 6 billion yuan, occupying a considerable share in the domestic market. It has a number of national patents, participated in the construction of a number of national key projects, and its products are sold at home and abroad with great influence. The pump valve enterprises in the county have developed 58 new products at or above the provincial level (including 17 at the national level) relying on factory run scientific research institutes, and more than 60 patented products. Yongjia Pump Valve Enterprise has established long-term economic cooperation with more than 40 domestic scientific research institutes and high efficiency, and has hired nearly 40 experts and professors to serve as the county government's science and technology consultants to guide the development of new products, the introduction and promotion of applicable technologies, etc. At present, nearly 100 enterprises in Yongjia County have obtained the right of export self operation. Especially in recent years, more than 200 new products have been developed, and pump and valve products have been widely used in various related fields. In view of the above successful experience, relevant enterprises throughout the country can learn from the development model of the county, and according to the local actual situation, specific analysis of specific problems, to find a development path with regional characteristics, and strive to become the next "Yongjia County".

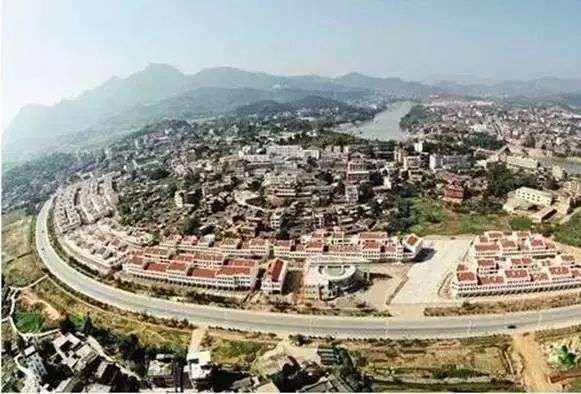

Nan'an, the city of water heating in China

Luncang Town, Nan'an City, located in Quanzhou, is a famous water heating city in China, which is currently the largest and most professional water heating market in China. At present, the construction of the third phase of China Water Heating City consolidates Luncang Town's professional market position, forms the world's largest international procurement center for water heating exhibition and trade, and introduces well-known brands at home and abroad, It is of great significance to establish the world's most authoritative technology exchange platform and information release platform, boost the formation and external influence of the plumbing production base and R&D base, expand the scale of the plumbing industry, and build a famous plumbing town in China. In order to further develop the "city of water heating", the injection of science and technology will bring it new vitality and new blood.

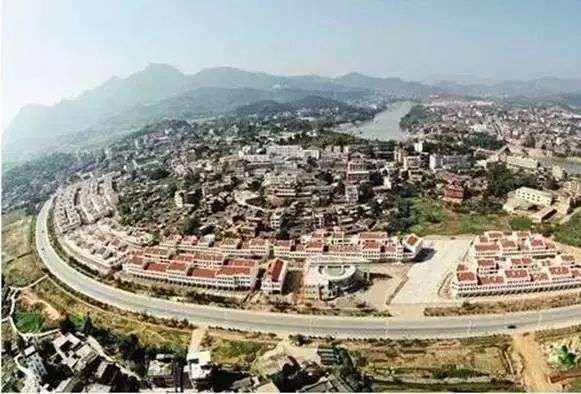

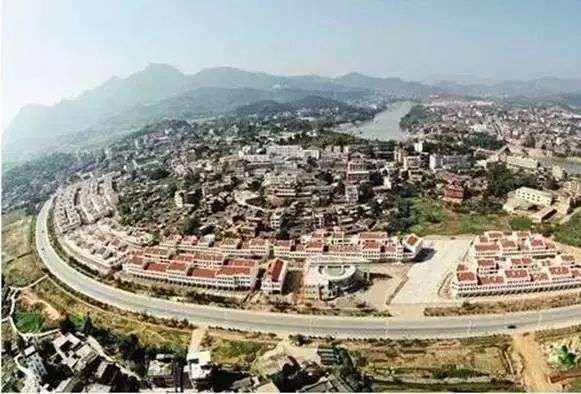

Linzhou, the production base of automobile castings in China

The automobile casting industry in Linzhou has developed rapidly. Linzhou, based on scientific development, adheres to the concept of "building the city through industry", bases itself on resource advantages, and vigorously cultivates and develops the auto parts industry, which has become the dominant industry supported and developed by Linzhou, driving the rapid development of smelting, casting, machining and automobile transportation industries. Now it has formed a large production base of automobile parts at the county level in China. Up to now, there are 520 automobile parts manufacturing and processing enterprises in the city, with more than 30000 employees. The annual casting production and processing capacity is 600000 tons, and 150000 water tanks, accounting for more than 40% of the national truck retail market. In order to integrate the casting industry in Linzhou, the local government has set up parks to improve the industrial agglomeration, promote the upgrading of the casting industry, and build a professional automobile casting cluster in China. In 2005, Linzhou built an automobile casting production base in Yaocun Town. The park covers a total area of 1480 mu, with a construction area of 480000 square meters, and a design investment of 500 million yuan. Its products are mainly used to produce automobile castings. To achieve cluster production, save farmland, improve product quality, reduce production costs and reduce environmental pollution, it was identified as a key industrial project in Anyang and Linzhou at that time. Today, the park is constantly deepening and improving. According to the latest planning, Yaocun Town Industrial Park is positioned to be dominated by auto parts industry, with the goal of complete casting, supporting the development of modern logistics, commercial trade, finance and insurance and other tertiary industries, and eventually developed into an industrial park based on the development of industrial and related industrial economic clusters, intensive use of resources, and functional integration, Make it a major production and export base of automobile castings in China.

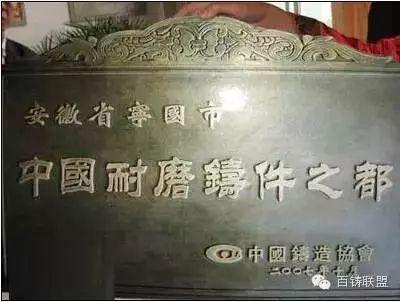

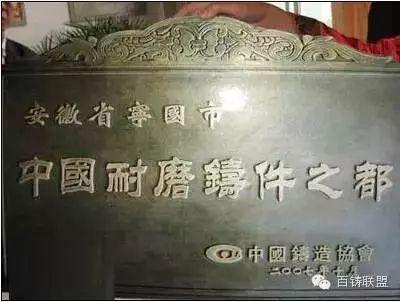

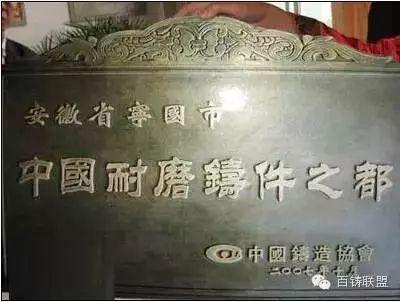

Ningguo, the capital of wear-resistant castings in China

Ningguo City is known as "the capital of wear-resistant castings in China". Since the early 1990s, the first wear-resistant material factory in Ningguo City has begun to build. Up to now, it has developed into a huge industrial cluster. After decades of wind and rain, it has become a major industrial pillar of Ningguo. With the development strategy of "strengthening the city through industry", Ningguo City actively guides and encourages enterprises to further enhance the comprehensive competitiveness of the wear-resistant casting industry of the city and promote the traditional industry to glow with new vitality by strengthening mergers and acquisitions, transformation and upgrading, listing and marketing. At present, Ningguo wear-resistant material market share accounts for more than 22% of the country, ranking first in the industry. Ningguo wear-resistant casting industry promotes merger and reorganization and takes the road of scale development. The city launched the integration plan of 100 enterprises, and set up a special fund of 3 million yuan every year to support and reward enterprises to choose the forms of equity participation, holding, acquisition, merger, joint venture, cooperation, merger and other mergers and reorganization, optimize the product structure, and enhance the overall advantages of the wear-resistant industry. China Building Materials Group Anhui Ruitai Wear resistant Material Headquarters, established by China Building Materials Group and Anhui Ruitai New Material Technology Co., Ltd., is located in Ningguo, focusing on building a headquarters economy integrating research, development, production, sales and service of wear resistant casting balls and heat-resistant castings. The total investment of the project is 300 million yuan, with the goal of completing the 80000 ton wear resistant material integration plan and achieving an output value of 600 million yuan. At present, there are 138 wear-resistant casting production enterprises in the city, including 8 enterprises worth 100 million yuan. During the "12th Five Year Plan" period, we will strive to integrate the existing 138 casting production enterprises to about 40. By the end of the "12th Five Year Plan", the wear-resistant casting industry of the city will achieve an annual production capacity of more than 1.2 million tons, an annual output value of more than 10 billion yuan, and 2-3 listed enterprises.

Jiahe, the capital of Jiangnan in China

Jiahe Foundry has a long history. It has been about 200 years since Tiangangtou Village began to cast plowshares. Jiahe Foundry has been constantly innovating and developing, and gradually developed into a major industrial county focusing on the foundry industry, enjoying the reputation of "casting capital in Jiangnan". Jiahe casting and forging industry attaches importance to the development of green casting. According to the different conditions of enterprises, there are key, orderly and diversified business development and innovation. In terms of casting materials, Jiahe Foundry has been constantly developing materials that are more suitable for users' products. It not only develops new materials that users need for new products, but also considers improving the quality of users' products, improving functional performance, and improving the materials of supplied castings. In order to improve the hardness, toughness, corrosion resistance, weight reduction, rare metal consumption, cost reduction and cutting performance of castings, research and development should be carried out to improve the casting materials. With the development of industrial technology, precision cast steel, nodular cast iron, vermicular cast iron and nonferrous alloys will be developed in the future. In recent ten years, in order to meet the needs of energy conservation and environmental protection The automotive industry has put forward higher and higher requirements for the material performance of diesel engines. The material of gray cast iron cylinder head can no longer meet the needs of the automotive industry. Vermicular cast iron has good strength, heat conductivity, wear resistance, corrosion resistance and heat fatigue resistance under the harsh conditions of high temperature, high pressure and poor lubrication. Cylinder head is a key basic part of diesel engines, The gray cast iron cylinder head produced by the traditional process can no longer meet the requirements of modern automobile industry, and the production of diesel engine cylinder head with vermicular cast iron has achieved good results. Cupola and electric furnace smelting process: among the smelting equipment currently used by Jiahe Foundry, the cupola accounts for about 60%, the electric furnace accounts for about 40%, and the cold air cupola accounts for about 60% of the total number of cupolas. The hot air cupola generally adopts the physical hot air supply mode, and the hot air temperature range is 150 ℃ - 250 ℃. It is the consensus of foundry enterprises to save energy, protect environment, reduce consumption, increase smelting output, and obtain high temperature and high-quality molten iron. The hot air and water-cooled cupola with long furnace life has not been popularized in Jiahe. The existing cupola of Jiahe Foundry Enterprise should properly change the air supply mode, furnace body structure, easy to use top heat storage water-cooled cupola, separate secondary air supply, oxygen injection from the cupola tuyere, natural gas, coal powder and metallurgical powder, which will improve the melting effect of the cupola. Zhejiang University of Technology has designed an induction furnace in front of the cupola for a foundry enterprise in Chaohu to raise the temperature of molten iron and ensure the outlet temperature of molten iron. In the future, cupola will develop in the direction of oxygen enriched air supply, natural gas, thermal storage, hot air water cooling, large tonnage, environmental protection and automation.

Luchuan, the capital of China's pot casting

Because of its good quality and low price, health care and environmental protection, Luchuan Iron Pot has always been popular with consumers. Its products cover all parts of the country. It is directly sold to Guangdong Midea Electric Appliance Group, Supor Electric Appliance, Shandong Jiuyang Group, Zhejiang Hangzhou Hongyang Group, etc., and its products packaged in other places are exported to Southeast Asia, where demand exceeds supply. At present, there are 17 iron pot production enterprises in Luchuan, all of which are private enterprises, and 6 enterprises above designated size. There are more than 15000 employees involved in the iron pot industry in the county. Every year, Luchuan produces various types of civil pots, industrial pots, pan, stainless steel rimmed pots, enamel pots, cooked iron pots, special pots for induction cookers, dual purpose pots for induction cookers and gas furnaces There are about 350 million cast iron pans of non stick pans and other series, accounting for 2/3 of the national production of iron pans, of which electromagnetic cast iron pans account for about 90% of the national special pans for induction cookers. In 2006, the industrial output value was 2.65 billion yuan, and the tax and profit was 189 million yuan.

China Foundry Network (http:/ http:// zhuzao.com )Committed to building a casting network big data platform,; A portal dedicated to enterprise services in the casting field. Provide professional casting industry information, casting business opportunities, casting investment attraction, casting exhibitions, casting enterprises and casting products.

Disclaimer: This image and text are from the Internet. For the purpose of transferring more information and learning, if the reproduced content involves copyright and other issues, please contact the editor immediately. The editor will change or delete the relevant content to ensure your relevant rights and interests