|

|

Collection | report

2023-12-07 21:14 Attention: two hundred and fourteen Answer: zero

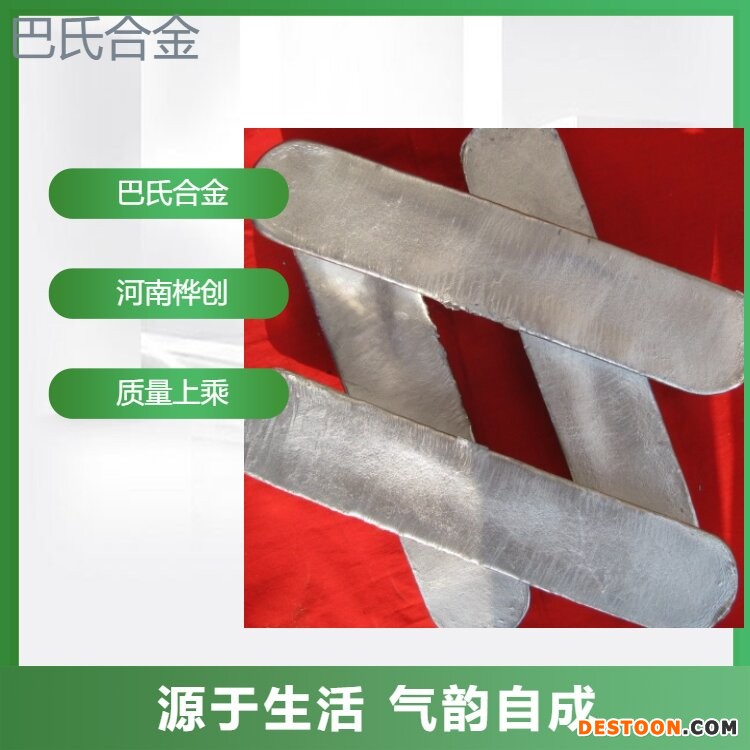

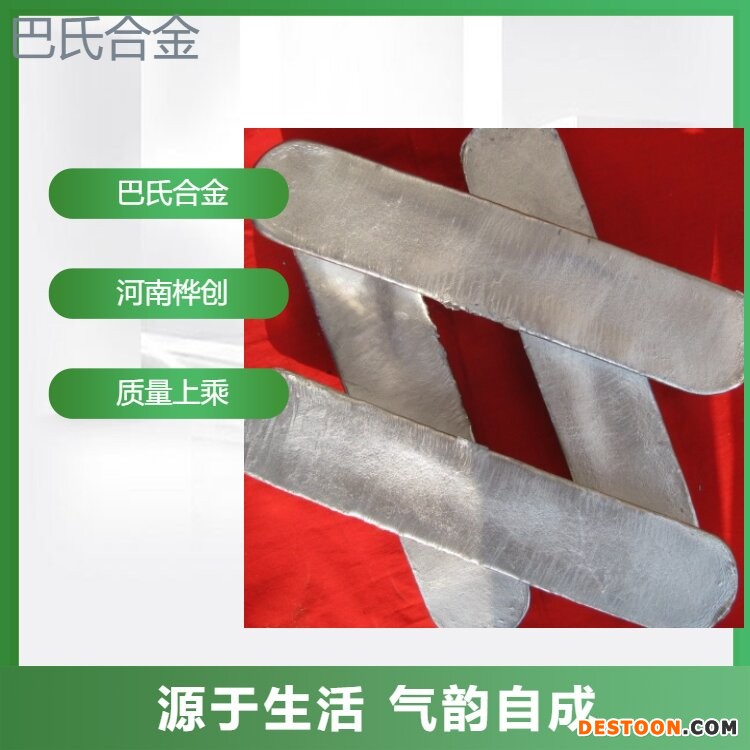

Valve sealing tin base babbitt tin bismuth alloy sealing block

To be solved To be solved

Reward points: 0

-Before the end of the problem Reward points: 0

-Before the end of the problem

Henan Huachuang Metal Materials Trading Co., Ltd. produces and sells babbitt alloy, tin base alloy, lead base alloy, bearing alloy, tin base babbitt alloy and babbitt bearing bush 。 The leading product is tin base alloy (4-4 melting point 225, hardness 28.6, suitable for various turbines, internal combustion engines, and high-speed bearing bushings. 8-4 melting point 238, hardness 34.3, high hardness, high load pressure, relatively suitable for large machine bearings and bushings. 11-6 Melting point 240 and hardness 30 are applicable to high-speed steam engines above 2000 horsepower and turbines, turbine compressors, turbine pumps and fast internal combustion engines of 500 horsepower.) The tin base babbitt alloy has the advantages of high temperature resistance, wear resistance, corrosion resistance, compression resistance, earthquake resistance, etc. Tin is the main element; There is also copper, antimony and lead. Because the tin base alloy structure is composed of soft matrix and hard points, when the sliding bearing works, the hard points in the matrix support the bearing and bear friction. The soft base ensures a good fit between the bearing and the journal. Therefore, tin base babbitt is exactly the casting machinery bearing bush, sleeve and bushing products. It is mainly used for cement ball mill, compressor, calender, water turbine, turbine, compressor, turbine pump, fast internal combustion engine, ball mill, mineral processing equipment bearing, metal ore mill, elevator, sling, steel wire rope fastening and other large machinery bearing bush, sleeve, bushing. It is also a filling product of mechanical seal, sling fastening, machine tool alloy sliding pad, grinder support pad casting block, sliding block, etc. Quality standard: conform to GB/T1174-1992 casting alloy standard; Character: blocky, with silver white metallic luster; The thrust pad sliding bearing is different from other sliding bearing pads. In the thrust bearing, it is used to fix the transmission shaft and carry the axial force from the transmission shaft (that is, the force direction is consistent with the axial direction), with thrust function. The part supporting the bearing in the thrust bearing is called the journal, and the part matching the journal is called the bearing bush. A bearing that operates under sliding friction. Under the condition of liquid lubrication, the sliding surface is separated by the lubricating oil without direct contact, which can also greatly reduce the friction loss and surface wear, and has a long life. It is commonly used in high-speed, heavy load components. The oil film also has a certain vibration absorption capacity, so the sliding bearing works stably, reliably, and noiseless. So customers choose tin base babbitt alloy.

|