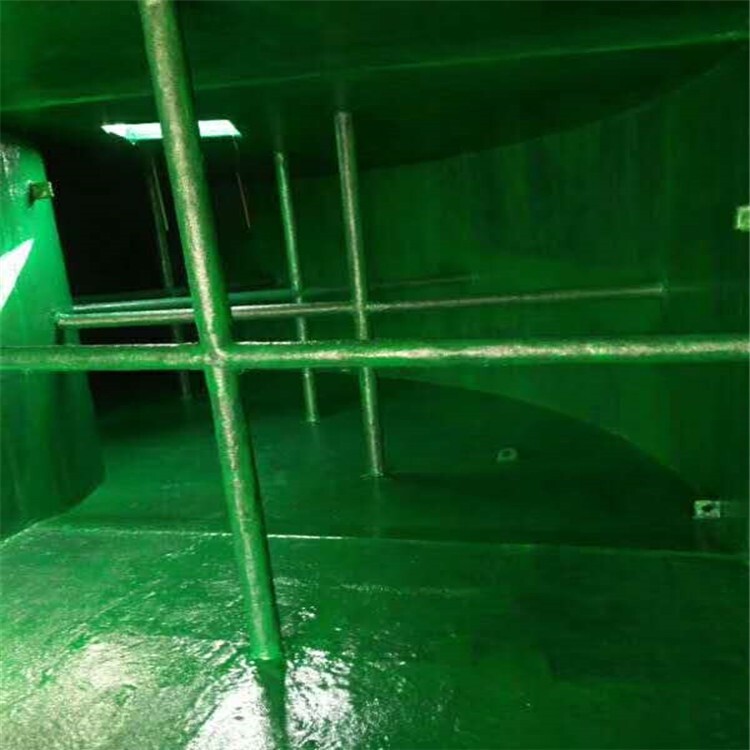

Epoxy glass fiber reinforced plastic coating is a kind of coating made of epoxy resin and glass fiber cloth, which has good corrosion resistance, wear resistance and high temperature resistance. Epoxy glass fiber reinforced plastic coating is commonly used in anti-corrosion and waterproof engineering, such as surface coating of water pump, storage tank, pipeline and other equipment, to improve equipment performance and reduce maintenance costs. The coating also has good UV resistance, and is not easy to fade and age after long-term use. It is suitable for outdoor environment.

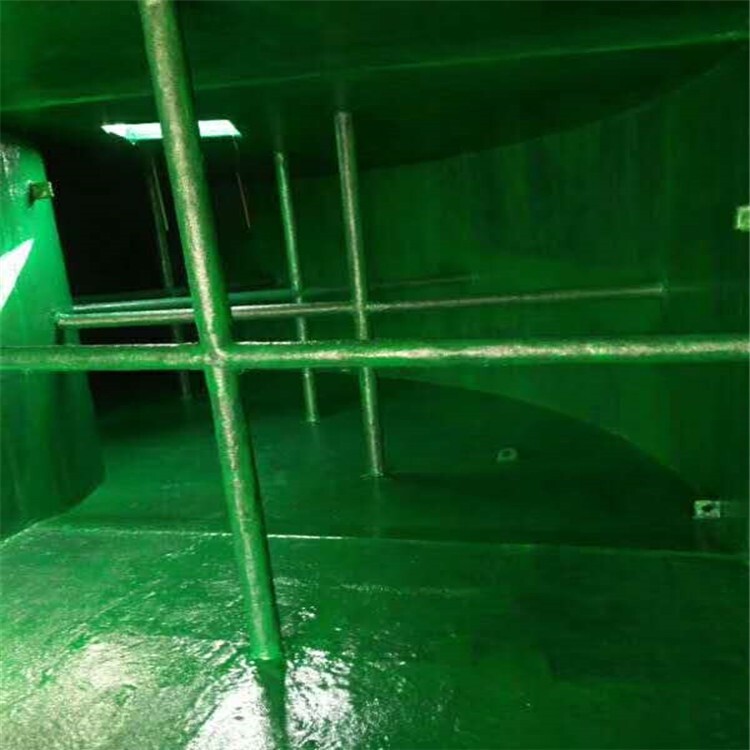

FRP anti-corrosion construction

Requirements for base course

The cement mortar or concrete base course shall be firm, dense, flat, and the slope and strength shall meet the design requirements. There shall be no sanding, hollowing, shelling, cracks, honeycombs, pockmarks and other phenomena; When flatness is checked with a 2m ruler, the allowable gap is not more than 5mm; The water content shall be no more than 6% when the thickness is 20mm. Before construction, the floating ash, cement slag and loose parts on the surface shall be cleaned up; The ground has been polluted by grease and chemicals and must be pretreated.

Material selection and quotation

There are many kinds of FRP resins, and there are hundreds of unsaturated resins alone. Therefore, materials shall be selected according to the medium, temperature and service conditions, so that they can meet the service conditions of the equipment system, especially with acid resistance and high strength.

quality requirement

1. All acid tanks shall be painted with resin before construction, so as to make the bonding more reliable. After curing, other cloths shall be soaked and pasted separately. It is required to remove bubbles. After the next layer of * * is cured, a layer of resin rich layer shall be painted after the burr is polished with an angle grinder.

2. The materials shall meet the quality requirements of the Construction Specifications. The mix proportion of the bottom layer, lining cloth and surface layer rubber shall meet the requirements, and the curing during and after construction shall meet the requirements of the Construction Specifications.

3. The appearance quality is free of fiber leakage, the resin is completely cured, free of pinholes, bubbles, wrinkles, peeling, delamination, and the rubber is full and the surface is flat.

4. Allowable deviation items; The allowable deviation of surface flatness and slope of ground FRP is the same as that of base course.

construction technology

Prime coat

1. Use epoxy anti-corrosive primer: mix the primer and curing agent in proportion and mix them evenly;

2. Roll coating evenly with roller without missing coating;

3. The door edge, wall corner, wall foot, machine foot, etc. shall be brushed with a brush.

Glass fiber cloth

Lay the glass fiber cloth, pour the prepared epoxy resin and curing agent onto the glass fiber cloth, and scrape it with a scraper.

Intermediate mortar

1. Use anticorrosive epoxy intermediate coating: mix the intermediate coating and curing agent in proportion and then add 40~100 mesh quartz sand to mix evenly;

2. Scrape for 1-2 times with a screwdriver;

3. After curing, grind and clean the defects such as the blade mark of the batch.

Putty layer

1. Use anticorrosive epoxy intermediate coating: mix the intermediate coating and curing agent in proportion and then add appropriate filler (such as quartz powder and talcum powder) to mix evenly;

2. Use a screwdriver to cover 1-2 times, which is to fill the holes on the ground;

3. After curing, polish the blade mark and other defects, and clean them with a vacuum cleaner, feather duster, etc.

Topcoat

1. Use anticorrosive epoxy surface coating: mix the surface coating and curing agent in proportion and stir evenly;

2. The roller shall be used for surface coating, and the roller coating shall be even. The coating shall be even without missing coating. The roller coating shall be twice, or the spraying shall be 1-2 times.

3. Solventless self flowing square pattern is adopted, and the surface is trowelled.

Technical indicators:

Project indicators

After stirring and mixing in the container, there is no hard lump and it is in a uniform state

Non volatile matter content,%, ≥ 75

Drying time, h, ≤ surface drying 4

Hard work 24

Adhesion (pull off method), MPa, ≥ 8

Wear resistance (1000g/1000r, cs-17),mg,≤ 250

Acid resistance (25% H2SO4 solution, 168h) without abnormality

Alkali resistance (25% NaOH, 168h) without abnormality

Salt spray resistance (1000h), no blistering, no rust, no falling off, adhesion ≥ 5MPa

Chloride ion penetration resistance, [mg/(cm2 · d)] 5.0 × 10-3

Note: Chloride ion penetration resistance is tested when the product is used in offshore engineering.

Construction reference:

Surface treatment:

Sand blasting: sand blasting reaches Swedish standard Sa2.5; Or power derusting to St3, and keep it clean and dry. Roughness: Rz=45 ~ 75 μ m.

Pre coating primer: the surface of the re coating shall be clean, dry.

? ? ?? Construction technology:

Recommended thickness: wet film: 80 μ m; Dry film: 50 μ m;

Diluent: epoxy diluent;

Tool cleaning: epoxy diluent;

Mixing ratio: 5:1

Maturation time: 25 ± 2 ℃) 30min;

Applicable period: (25 ± 2 ℃) 6 hours

1. Weigh the two components in proportion, slowly pour the curing agent into the main paint, and mix evenly. Let stand for 10~30min (maturing stage).

The prepared paint shall be used up within the applicable period.

2. Add thinner to adjust the construction viscosity according to the construction method and paint type.

? ? ?? Construction method:

High pressure airless spraying, pneumatic spraying, manual brushing and roller coating

Large dilution 0~15% 5%~20% can be used

Orifice 0.53~0.66mm 2.0~2.5mm

Ejection pressure 17 ~ 20MPa 0.3 ~ 0.4MPa

Drying and coating interval

Substrate temperature, drying time, coating interval

The surface dry is shorter and the solid dry is longer

20℃ 2h 24h 24h

Basic Introduction

Epoxy glass flake coating is a kind of epoxy coating with strong shielding property. It can be applied in thick layer and has anti-corrosion properties for acid, alkali, solvent, seawater, oil, etc. The shielding property of epoxy glass flake paint mainly comes from glass flakes in raw materials, and its characteristics are also reflected in the paint.

Glass flake characteristics:

Strong shielding.

Strong resistance to acid and alkali.

Strong water resistance.

Corrosion resistance.

Good workability of thick coating.

Good mechanical performance.

Epoxy glass flake heavy anti-corrosive paint/anticorrosive paint Application:

This product is suitable for ships, ports, railway bridges, petroleum, chemical smelting, steel facilities, pipelines, sewage treatment plants, and concrete surfaces, so as to protect them from the corrosion of atmospheric, seawater, acid, alkali, oil, salt, chemical gases and other corrosive media.

Application interval of epoxy glass flake heavy anti-corrosive paint/anti-corrosive paint:

The temperature is 5 ℃ * * short interval 24h, * * long 5d.

The temperature is 20 ℃ * * short interval 16h, * * long 3d.

The temperature is 30 ℃ * * short interval 8h, * * long 2d.