Properties of glass flake coating

1. Chemical resistance

Commonly used epoxy resin and unsaturated polyester resin based flake coatings have good corrosion resistance to acid, alkali, petroleum solvent, various salts and water.

2. Physical and mechanical properties

A large number of glass flakes are filled in the coating of resin based glass flake coating, which improves the mechanical strength, surface hardness, wear resistance and adhesion; At the same time, the thermal expansion coefficient and curing shrinkage of the coating are reduced, and the resistance to thermal shock and heat resistance are increased.

3. Weather resistance

The refractive index of glass flakes is quite different from that of resin, and its surface is slightly curved. It can reflect a lot of ultraviolet rays when arranged in parallel in the coating, thus reducing the aging of resin.

4. Dielectric property

Synthetic resin is an insulator, but its dielectric property will deteriorate in wet environment, so that it cannot be used in high insulation occasions. Glass flake is an insulator, which also has excellent water vapor permeability resistance. Measurement shows that the resin sample filled with glass flake has 10 times less water vapor permeability than the unfilled one, so it has excellent insulation when working in wet environment.

In addition, glass flake coating also has the following characteristics:

? 1. The permeability to chemical medium, gas and steam is much smaller than that of glass fiber reinforced plastic lining, and it is difficult to cause the phenomenon of water vapor diffusion. This is because the glass flakes arranged in overlapping layers make the medium penetrate a long distance.

? 2. The shrinkage is low during curing, and the residual stress on the bonding surface is small due to dispersion.

? 3. The thermal expansion coefficient is small, the adhesive thermal stress is correspondingly small, the heat resistance temperature is high, and the heat resistance impact performance is good.

? 4. Although the mechanical strength is not as good as that of glass fiber reinforced plastic lining, the abrasion resistance and scratch resistance are excellent, and the mechanical damage is limited to local areas.

? 5. Application process performance of glass flake coating.

? Because glass flake coating has many advantages such as corrosion resistance, good permeability resistance, low film shrinkage, small coefficient of thermal expansion, less curing residual stress, abrasion resistance, simple construction, easy repair, etc., glass flake coating is widely used in chemical industry, metallurgy, chemical fiber, electroplating, architecture and other industries. Especially, it is widely used in various marine engineering equipment, offshore oil and gas platforms, harbor terminals and ships.

Construction description;

1) The dosage of component A+component B is 0.3-0.4Kg/m2, and the construction time limit is 4 hours.

2) Mix all components of the coating evenly according to the ratio requirements, and scrape or roll coat them evenly with a trowel.

Construction conditions;

1) The concrete surface shall be flat, clean, clean and free of oil stain.

2) The steel structure surface shall be clean, clean and free of oil stain. Use power tools to remove rust to St3 or sand blast to remove rust to Sa2.5.

Product characteristics;

1. Chemical * * *, good corrosion resistance and weather resistance.

2. The consolidated body has high cohesive force, high compressive strength and is not limited by the structure shape.

3. It has the function of reinforcement.

Scope of application

1. It is suitable for sealing and anti-corrosion of underground pipeline, hydropower station, dam foundation and other interfaces.

2. It is suitable for repairing cracks and honeycombs in beams, columns and pile caps of buildings.

3. It is suitable for bonding steel structure and concrete, and can be made into wear-resistant floor.

4. It is used to protect the flow surface of hydraulic structures against erosion, cavitation, freezing and thawing, and repair after damage.

Product composition:

Epoxy glass flake anticorrosive coating is a two-component coating, mainly composed of epoxy resin, glass flake as main raw materials, anti rust pigment, curing agent

It is composed of solvent, auxiliary agent and diluent.

?

Main features:

1. * * * Enhance corrosion resistance and effectively protect bottom materials.

2. After the film is formed, it has strong shielding, can effectively prevent the penetration of corrosive media, and achieve the purpose of isolation and rust prevention.

3. High mechanical strength, wear resistance, and water impact resistance.

4. Oil resistance, water resistance and solvent resistance.

5. Good mechanical properties, tough and impact resistant paint film.

6. Because of its strong adhesion and firm adhesion, the coating on steel will not fall off.

7. High solid content, can be used as thick film paint with good solvent resistance

Scope of application:

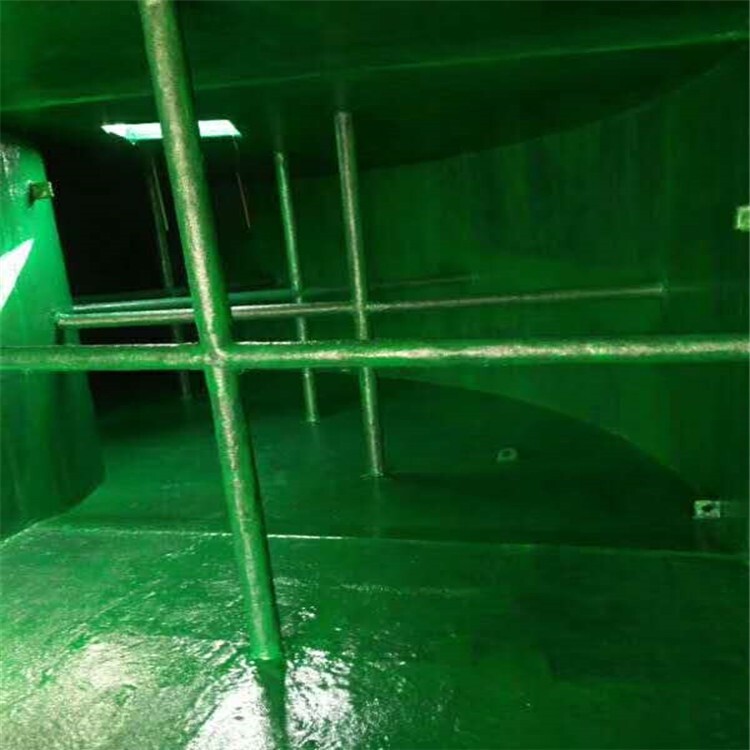

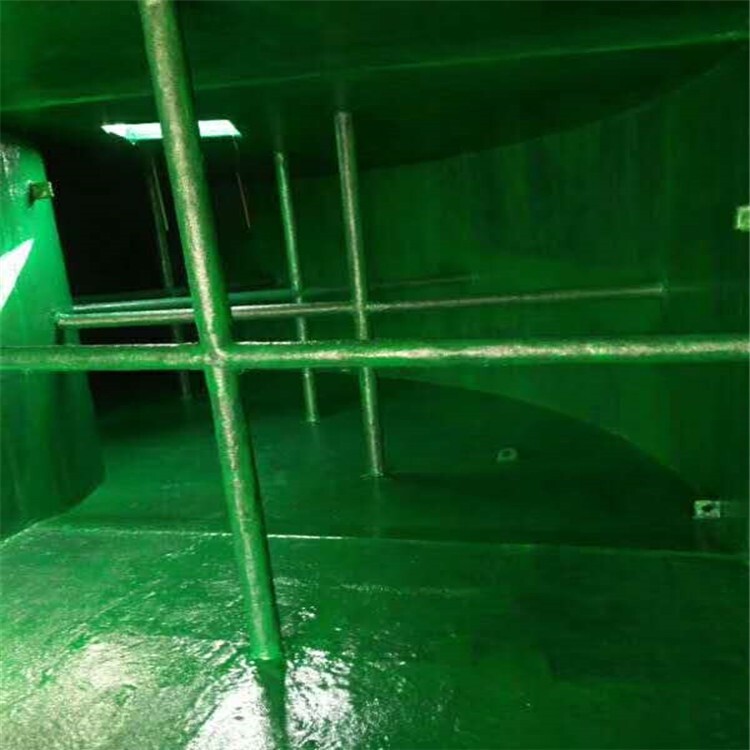

It is mainly used for desulfurization tower anti-corrosion, steel plant anti-corrosion, sewage pool anti-corrosion, power plant anti-corrosion, pipeline anti-corrosion construction, chemical plant anti-corrosion, oil tank anti-corrosion, heavy industry anti-corrosion, flue anti-corrosion, chemical equipment, containers, ships, storage tanks, bridges, underwater parts of hull and steel structure equipment in ballast tanks, crude oil tanks, waste oil, sewage environment Offshore platforms, concrete structures and other facilities can be used not only for new structures, but also for the maintenance of existing structures.

Surface treatment:

The paint base shall be clean and free from all dirt such as oil stain and dust.

Sand blasting or shot blasting shall reach Swedish Sa2.5 level, and mechanical derusting shall reach St2-3 level.

Matching paint:

Previous coat: epoxy iron red antirust paint, epoxy zinc rich primer, epoxy red lead antirust paint, epoxy micaceous iron intermediate coat

Next layer: epoxy anticorrosive finish, chlorinated rubber anticorrosive finish, metal finish

Construction ratio:

Open the big mouth of component A, add component B into component A, and mix well. After 20-30 minutes of curing, coating can be carried out. This material is required to be used at any time, and the paint after mixing must be used up within four hours. The unfinished materials shall be sealed and stored.

Epoxy glass flake coating

Technical parameters:

Color and appearance of paint film: various colors, flat paint film

Viscosity (coating - 4) s: not less than 50

Fineness, μ m: no more than 50

Solid content: 65%

Impact strength, kg, cm: not less than 40

Salt water resistance (3 days): no blistering and rust

Vapor oil resistance: 24h, no blistering, no wrinkling, no gloss loss

Weather resistance: artificial accelerated aging: 1000h;

Hardness (swing rod): not less than 0.6

Dry film thickness: 150 microns (dry film)

Storage life: 1 year

Adhesion: ≤ 1 (cross cut method, grade)

Applicable substrate: steel, cement

Painting reference:

Coating method: airless spraying, air spraying, roller coating, brush coating

Ratio: paint: curing agent=20:4 (weight)

Maturation time: 30 minutes

Applicable period (25 ℃): 8 hours

Theoretical dosage: 8-10 square meters/Kg/pass (dry film thickness 30 μ m)

Recoating interval (25 ℃): more than 24h

Construction conditions: construction temperature 5-38 ℃, air relative humidity less than 75%

Package specification: 25kg/barrel