Equipment alias: aluminum refining degasser aluminum water refiner aluminum liquid hydrogen remover aluminum soup refining slag extractor

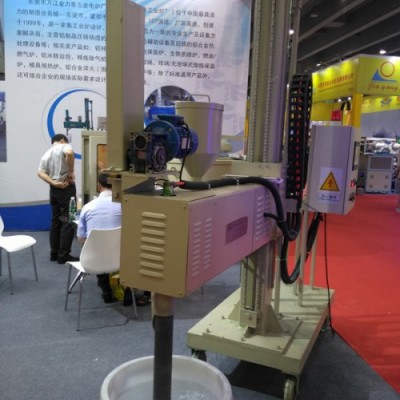

One button processing workstation for aluminum liquid (metal liquid)

Why use aluminum refining degasser?

During the melting process of aluminum alloy, the molten aluminum will react with water vapor to produce hydrogen and dissolve into the molten aluminum. When the molten aluminum solidifies, hydrogen will be separated from the molten aluminum. If the hydrogen content in the molten aluminum is too high, pores (pinholes) will easily form in the castings, and the mechanical properties of the castings will decline, which will lead to the rejection of the castings in serious cases. Hydrogen is a harmful gas in molten aluminum. The pre furnace detection of hydrogen content in molten aluminum is an important process to ensure the quality of castings. Especially when large capacity furnaces are used for mass production, the use of aluminum refining degasser for hydrogen removal and slag removal will become indispensable. All precision casting manufacturers have high requirements on the purity of liquid aluminum (zinc), especially those making auto parts, motorcycle parts, and precision casting. They will use degassers to mix, degas, slag, and refine liquid aluminum (zinc) to improve the purity of liquid aluminum (zinc) and achieve the goal of producing aluminum (zinc) castings with high quality, high efficiency, and low cost.

Operating principle of degasser for aluminum refining:

The principle of the degasser is that the rotating rotor breaks the inert gas (argon or nitrogen) blown into the aluminum water into a large number of dispersed bubbles, which are dispersed in the aluminum liquid; Bubbles in the molten liquid absorb hydrogen in the molten liquid, absorb oxidation slag inclusion, and are brought out of the molten liquid surface as the bubbles rise, so that the molten liquid can be purified; As the bubbles are fine and dispersed, they are evenly mixed with the rotating molten liquid, and then slowly float up in a spiral shape. When contacting with the molten liquid, the air flow generated by continuous straight rise will not be formed, thus significantly improving the purification effect. Argon and nitrogen can be used for degassing aluminum liquid. The purity of inert gas must be above 99.99%.

Application scope of degasser for aluminum refining:

This degasser is applicable to the dehydrogenation, slag removal and purification of aluminum liquid in crucible furnace, pool furnace, reverberatory furnace, ladle and static box.

Specific industries include: Aluminum casting, copper casting, propeller, copper wire, copper rod, copper ingot, copper parts, aluminum alloy casting, aluminum alloy casting, aluminum processing, aluminum plate, aluminum foil casting, motorcycle parts, auto parts, automobile hub, engine piston, engine, elimination of air holes, sand holes, pinholes; Integrated melting furnace, crucible, ladle lifting, transfer ladle, online launder; Crucible boiler, holding furnace, draw shaft, upper draft furnace, medium frequency furnace, etc.

Our aluminum refining degasser equipment is widely favored by the die casting and casting industries, and has been sold to Guangdong, Fujian, Chongqing, Hunan, Jiangxi, Liaoning, Jiangsu, Zhejiang, Shandong, Henan, Inner Mongolia, Xinjiang, Anhui, Yunnan, Shaanxi, Shanxi, Ningxia, Heilongjiang, Hebei, Jilin, Shanghai, Gansu, Guizhou, Qinghai, Guangxi Dozens of provinces and cities, including Tibet, have served thousands of enterprise customers and received unanimous praise.

Features of degasser for aluminum refining:

1. The mobile degasser can be pushed and moved manually, and the positioning is convenient; Only one subcontractor can use it safely.

2. The hydraulic or lead screw lifting device (with limit switch) has accurate rotor positioning and is convenient for replacement;

3. Simple control, button operation, degassing time can be set, automatic/manual control mode is available, and automatic control is generally used

May; After the degassing time is set, all actions of degassing can be completed with one key by using automatic control;

4. When the set degassing time is completed, the rotor stops running, the gas supply is automatically closed, the cantilever is automatically lifted, and the indicator light flashes

Shutdown to remind the operator, high safety; When the pressure of inert gas is less than the set pressure, the equipment will automatically alarm and remind the operation

Personnel shall replace the air source in time;

5. Using nitrogen or argon as degassing medium, advanced degassing principle greatly reduces degassing time, improves efficiency and reduces

Refining cost, no pollution to the environment, and greatly improved working environment;

6. The flow of inert gas is controllable and can be set reasonably, which can greatly reduce waste products caused by bubbles and inclusions and greatly improve

Yield, improve the mechanical properties of castings;

7. It provides stable and repeatable degassing effect, which can achieve efficient and high-quality production for customers without affecting the production process;

8. No corrosion on ladle or crucible boiler lining;

9. Optional baffle; The function of baffle: make the surface of aluminum liquid stable during degassing, and reduce the secondary pollution during treatment;

10. The main shaft and motor of the equipment are equipped with air cooling devices, which can effectively reduce the working temperature of the main shaft and motor and extend the service life

Life.

11. It is equipped with emergency shutdown button, which is simple and safe to switch on and off, and the equipment structure compact Firm, simple maintenance, low maintenance requirements.

![4T0G}QRS8)5[{BNG3]4AJSO](https://www.yzw.cc/skin/st05skin34xha/image/lazy.gif)

Main technical parameters of degasser for aluminum refining:

1. Rated power supply: 3-phase, 380V, Rated frequency: 50HZ.

2. Rotor spindle motor power: 0.75KW; Movable arm lifting motor power: 0.75KW.

3. The reducer is aluminum shell RV75 type with a speed ratio of 1:100.

4. Refining time: 10~30 minutes. The timer is 0-999min (the time can be set automatically).

5、 Rotor speed: 0~600 rpm/fraction display adjustable, gas flow (0.25~2.5 Nm3/h) adjustable.

6. Graphite rod: diameter 70mm * length 800mm, graphite rotor: diameter 180mm * thickness 45mm.

7. Effective length of cantilever: 950mm ground (furnace or running bag with diameter less than 2m or used).

8. Refining gas: argon or high-purity nitrogen for drying industry (purity greater than 99.996%).

9. Gas input pressure: 0.4~0.6MPa;

Classification of degassers for aluminum refining

1. Hoisting refining degasser/slag remover → Model: JLTCQJ-101

2. Mobile refining degasser/slag remover → Model: JLTCQJ-102 (conventional)

3. Mobile powder feeding refining degasser/slag remover → Model: JLTCQJ-103 (automatic powder feeding)

4. Rotary powder feeding refining degasser/slag remover → Model: JLTCQJ-104 (manual rotation)

5. Rotary powder feeding refining degasser/slag remover → Model: JLTCQJ-105 (electric rotation)

The degasser is mainly used for: It is suitable for crucible with inner diameter of φ 200~2000mm, crucible furnace, draw well, large ladle lifting, etc.

after-sale service:

1. The equipment is free of charge for one year for non man-made damage during normal use, and enjoy preferential maintenance service for life.

2. Within one year from the date of purchase of the equipment, our company will provide free maintenance if the equipment fails when the user uses it normally according to the Operation Manual. During the free maintenance period, after receiving the written notice from the user, we will first guide the user to deal with the fault by telephone or video. If the fault cannot be dealt with by telephone or video, we will arrange technicians to arrive at the site within two to three working days (24 to 48 hours in the province) 。

This equipment can be customized according to customer requirements.

![4T0G}QRS8)5[{BNG3]4AJSO](https://www.yzw.cc/skin/st05skin34xha/image/lazy.gif)

![4T0G}QRS8)5[{BNG3]4AJSO](https://www.yzw.cc/skin/st05skin34xha/image/lazy.gif)