Since the establishment of Julun Equipment for six years, its product sales have been rising steadily, and its position in the field of robot automatic polishing has slowly begun to take on a significant position. Become a respected brother in the industry.

The reporter from Die Casting Network and his party went out under the scorching sun to interview Mr. Bi Hui, the general manager of the company who was not used to taking a rest at noon and still led everyone to work

Bi Hui, General Manager of Giant Ship Equipment

Zou Wangqin and his party from China Die Casting Network took a group photo with Bi Hui, General Manager of Giant Ship Equipment

Reporter: Mr. Bi, five or even ten years ago, some robot automation integrated application enterprises entered the die-casting field, hoping to help die-casting factories liberate from the tedious polishing, high-strength, high-risk, and highly polluting work, which is called machine replacement. However, the facts later proved that most of the pioneers failed, and some of them no longer existed. Mr. Bi, what do you think is the main reason for their failure?

Mr. Bi: From the commercial point of view, the results of the pioneers are not so ideal. Most of them are experiencing business contraction, or even suspension of development. However, from the perspective of technology development, these pioneers must be successful. At least they have completed the first round of technology exploration and achieved a certain accumulation and development iteration foundation.

On the one hand, the reason for business contraction is that the layout of "robot replacement" is too fast, which leads to the inability of the industry ecology and ecological volume to quickly adapt to and meet its development.

On the other hand, it is the negative impact of the irresistible economic downturn that some pioneers have to passively slow down, so the appearance of "a wave of pioneers failed" appears. As for technical progress is a success and a development, the exploration of the market environment is undoubtedly successful. The management of the die-casting industry needs to be further standardized, which is exposed thoroughly in the process. The problems caused by the failure to consider the back-end process upgrade in the product design process are also exposed thoroughly, The corrective solutions that accompanied the problem exposure in the process have greatly promoted the development of the pioneers, and the related core technologies have also achieved rapid development, which paves the way for the development of iteration.

In general, failure is partial, and success and development are the main factors. thank you.

Reporter: I saw so many modern people either fall down or struggle to move forward. When everyone is not optimistic about it, why does your company dare to set foot in this field and have to wade into the muddy water of die casting robot polishing and polishing?

Mr. Bi: I want to answer this question in two levels.

1、 The operation of robot polishing or die casting industry polishing is not carried out behind the fall and struggle of everyone. The field of giant ship equipment foreshadowing operation is fully in accordance with the needs of the strategic development of the Group and its subsidiaries, and has been operating steadily step by step for nearly 10 years. Over the years, the giant ship equipment has deeply analyzed the market environment and industry demand, committed to the research and development of the underlying technology in the field of robot polishing, and committed to the research and practice of engineering application technology. Business and technology development are controllable within the development plan of the Group and its subsidiaries.

2、 I think it is a kind of courage and a reflection of the value of the existence of the enterprise to face the contradictions and difficulties of the giant ship equipment. The giant ship equipment believes that the breakthrough of the core technology is the key to solve the problem, and the research practice of engineering application can drive the standardized development of the industry, so as to achieve sustainable development. At present, the key technologies of Julun equipment, such as flexible force control system and teaching free intelligent system for robot polishing, have made great breakthroughs, and have been gradually applied to core customer groups, receiving good feedback.

Reporter: Mr. Bi, your company has set up factories in Zhongshan and Dongguan to process die-casting parts with supplied materials. This shared factory model requires great strength investment and may cost a lot of money. But it can promote product R&D and upgrade, and cultivate potential customers. Am I right?

reporter: First of all, potential customers need to be cultivated, but at the same time, potential customers are equal to other equipment manufacturers in the market. The original intention of sharing the establishment of the factory is that the proportion of developing potential customers is relatively small. In other words, the operation of the factory is not entirely to develop potential customers. It is the original purpose to promote the R&D and upgrading of products through the operation of the factory, so we would also like to thank relevant customers for exploring the feasibility of process upgrading together in the new robot polishing shared factory, and at the same time, both parties have achieved certain economic benefits.

Reporter: Mr. Bi, what's your next plan? thank you

Mr. Bi: With the continuous breakthrough of core technology, the company will continue to make efforts in this field. Increase investment on the basis of the original market and technology layout, first complete the focus of specific industries, including die-casting hardware, heavy industry, aerospace, military industry and other fields, improve and form comprehensive solutions, and achieve a revenue scale of 100 million to 200 million in the next 2-3 years 。 At the same time, in order to promote the upgrading of product process, the giant ship equipment will also try to develop intelligent equipment and solutions for peripheral assembly line centering on the polishing process, which will realize the intelligent assembly line of equipment for front-end manufacturing process, logistics, polishing, and back-end manufacturing (some) process, so as to better improve the equipment use experience and bring maximum economic benefits.

After the interview, reporter Zou Wangqin was lost in thought, "Machine replacement" is not only a national strategy but also a long-term systematic project! For decades, many enterprises have invested huge amounts of money and effort in this field, and most of them have finally lost their lives or become short-lived! But it doesn't have to be me! It is the footsteps of thousands of pioneers who have stepped out of today's broad road!

Bless the giant ship equipment! Bless machine replacement! Bless China!

About giant ship equipment

Julun (Guangzhou) Intelligent Equipment Co., Ltd. (hereinafter referred to as "Julun Equipment") is a joint venture subsidiary of Julun Intelligent Equipment Co., Ltd. (stock code: 002031; hereinafter referred to as "Julun Intelligent"). The technical team consists of more than 100 undergraduate, master and doctoral talents. Julun Intelligence is one of the national key high-tech enterprises, national innovation demonstration enterprises, one of the fifteen national robot standard enterprises, one of the fifteen backbone robot enterprises in Guangdong Province, and has been recognized as a new research and development institution in Guangdong Province

Company building

Julun Equipment is a service provider providing robot polishing, deburring, machining automation products and intelligent logistics, visual inspection and intelligent training overall solutions, committed to becoming an intelligent post-processing expert in die casting, casting and forging; It mainly serves many industries such as auto parts, new energy, smart home, communication equipment structural parts, building bathroom hardware, medical equipment, aerospace and military industry, wooden plastic products and sports equipment.

Core advantages of the enterprise

Professional team: Professional mechanical and electrical design, process development, robot commissioning implementation team

modularization: Modularization of mechanical structure, modularization of electronic control system and robot polishing program, and rapid customization of polishing system

Intelligent compensation: Grinding pressure compensation, grinding wheel wear compensation and rapid production change: meet the needs of multiple varieties and small batches through rapid programming and flexible fixture technology

Intelligent monitoring: Consumable life management, equipment status monitoring, capacity report, docking with enterprise MES system

Simple operation: The robot is easy to operate without professional programmers

Big process data: Grinding and polishing share the massive process data accumulated by the factory, and realize the whole process production of sanding, matting, mirror polishing and deburring

Quick customization: Quickly customize polishing process, equipment and dedusting room according to customer needs

Standard products

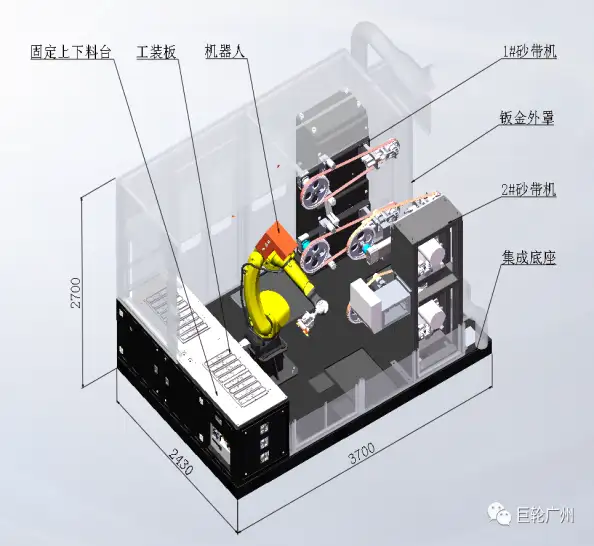

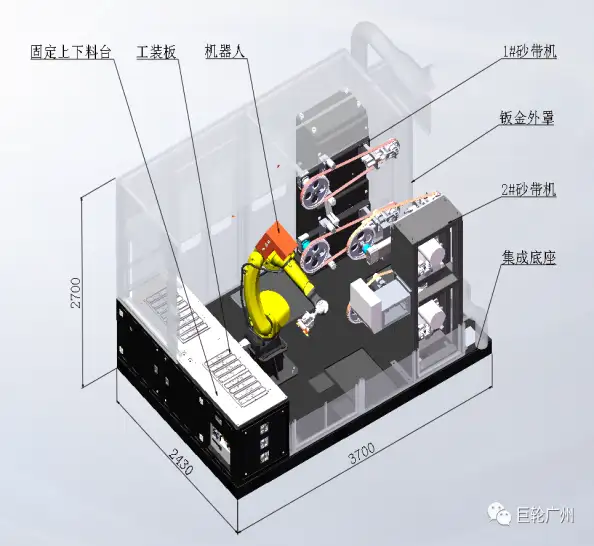

The robot polishing standard unit is a closed robot workstation, which consists of the robot body, fixed loading and unloading table, tooling plate, abrasive belt machine and integrated base. It is equipped with contact force compensation plug-in, consumable wear compensation, and abrasive belt correction functions to solve product deviation and consumable wear problems and ensure consistent quality and stable production. The standard unit has the advantages of flexible configuration, wide adaptability, high cost performance, short supply cycle, rapid installation and commissioning, etc.

| content |

parameter |

| Total power |

20KW |

| Actual power used |

7KW |

| Voltage V/Hz |

380/50 |

| pressure |

05~0.7Mpa |

| area covered |

Length 3.7m * width 2.43m * height 3m (excluding dust removal equipment) |

| Operating temperature and humidity |

Temperature - 10~40 ℃, relative humidity ≤ 85% |

| Maximum workpiece size for grinding |

L800*W800*H800 |

| Adapt to workpiece deviation |

±2mm |

| Total weight of equipment |

≤5000KG |

Parameter configuration

| Optional module |

| Deburring module |

According to whether the workpiece needs deburring |

| Detection module |

According to whether the workpiece has size detection requirements |

| Dust concentration detection module |

Whether it is necessary to detect the dust concentration in the protection room |

| Dust removal system module |

Dust removal system module |

| Fanuc 20iD-25/1.83 |

Select according to the actual situation of the customer |

| ABB 2600-20/1.65 |

| KUKA KR20/1.61 |

Product application field

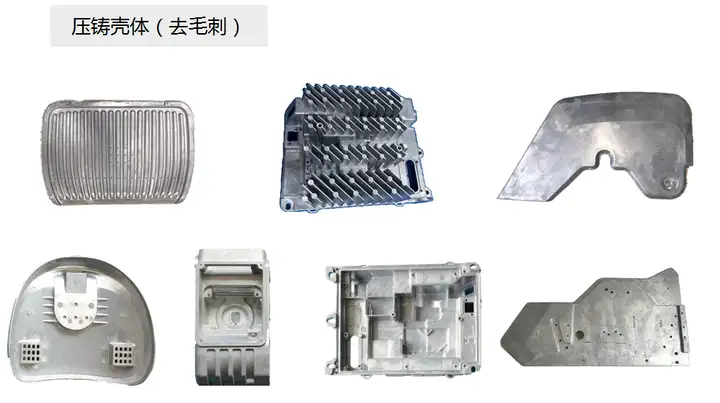

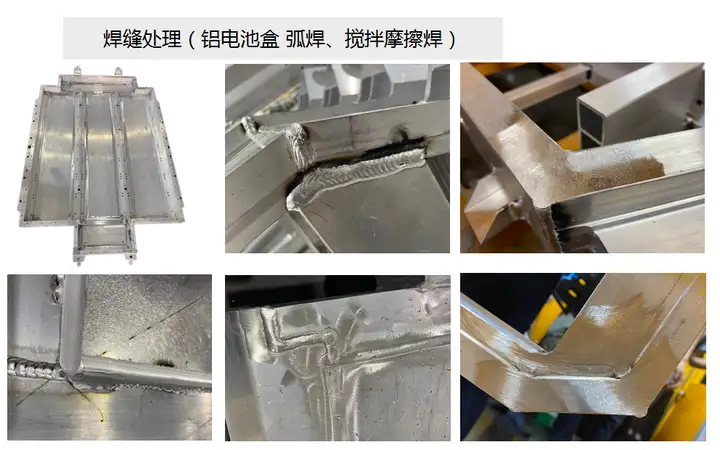

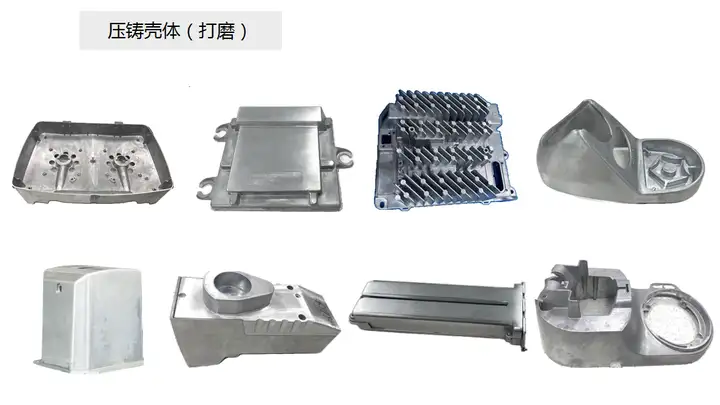

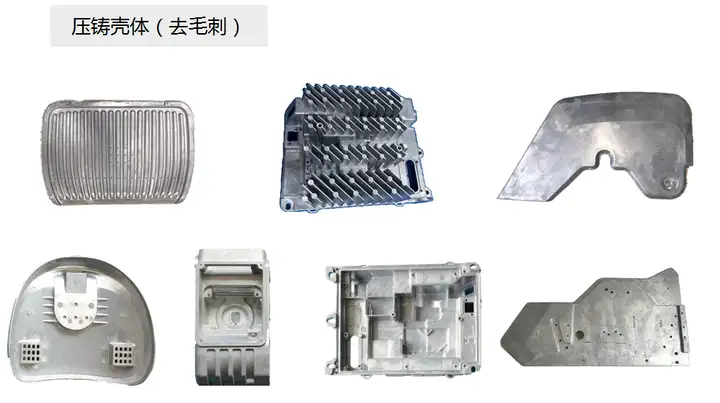

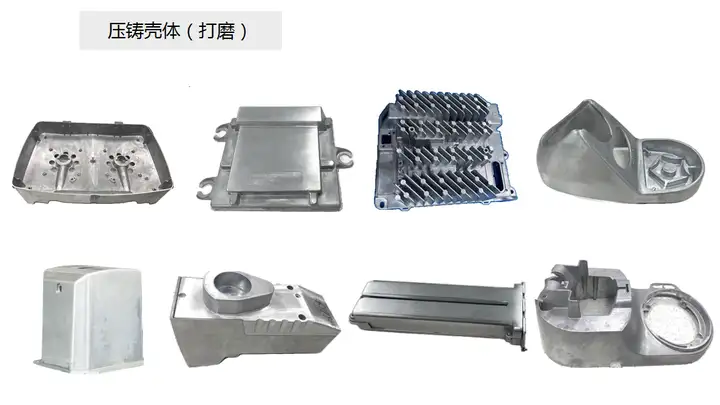

The robot grinding workstation can be used for grinding different materials of special-shaped parts, such as aluminum alloy, zinc alloy, copper alloy, titanium alloy, stainless steel, wood products, plastic parts, electroplating parts, etc.

Typical industries and products:

Smart lock: Smart lock panel and handle

Building hardware: Door handle and handle seat, connecting claw, guardrail

Bathroom hardware: Faucet zinc alloy handle, copper, stainless steel faucet body, temperature control body

Tools and hardware: Wrench, hammer, etc

Auto parts: New energy die-casting housing, bumper, car handle, wiper, trim strip, guide rail, hub, engine housing

Structural members of communication equipment: 5G base station, radiator, filter, mobile phone, tablet, etc

Military aerospace: Gearbox, nose, tank track, turbine blade

Sports equipment: Golf head and club

medical apparatus and instruments: Artificially implanted joint (knee joint, hip joint)

High speed railway ships: Propellers, yacht accessories, high-speed rail accessories, etc.

Classic case display

Cooperation negotiation

Julun (Guangzhou) Intelligent Equipment Co., Ltd

Main products of the company:

Provide overall solution for polishing and deburring

Equipment sales and leasing

technical service

OEM service

Company contact person and telephone:

Mr. Bi 18520218259

Enterprise website : http://www.greatoo-ie.com/