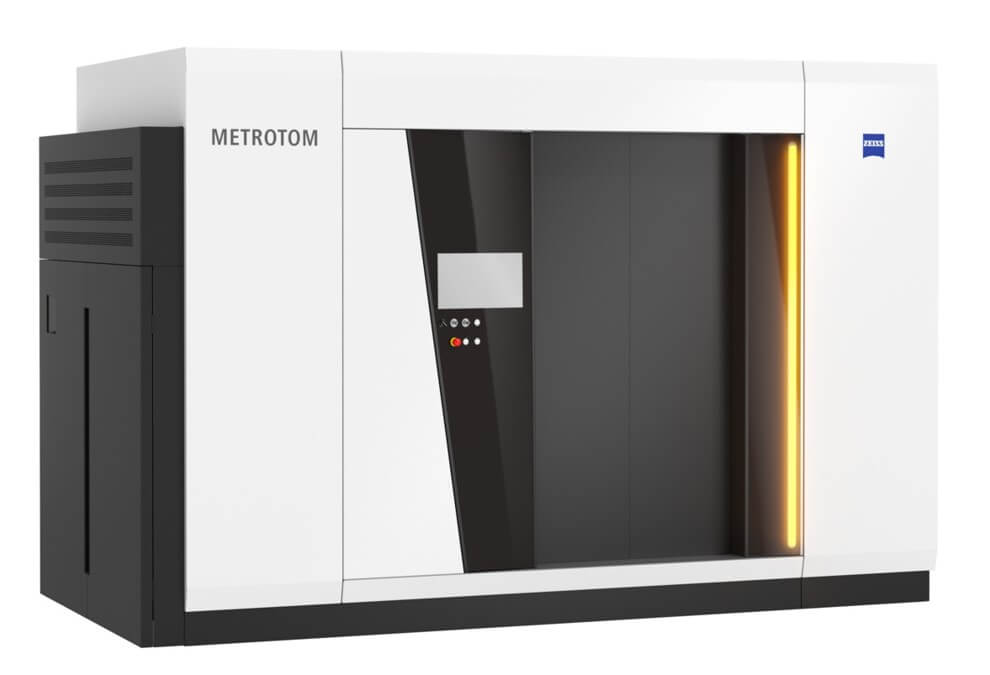

ZEISS Industrial CT - ZEISS METROTOM 800&1500

ZEISS INDUSTRY CT-ZEISS METROTOM 800&1500

Innovative technology

ZEISS Industrial CT ZEISS METROTOM 800/225kV HR

Good image quality

Open reflective X-ray tube

Smart design

Testing medium and large parts

Reliable measurement results

ZEISS Industrial CT ZEISS METROTOM 1500

Better image quality

Speed up scanning

Smart structural design

Can detect larger parts

Reliable measurement results

ZEISS INDUSTRY CT-ZEISS METROTOM 800&1500

characteristic

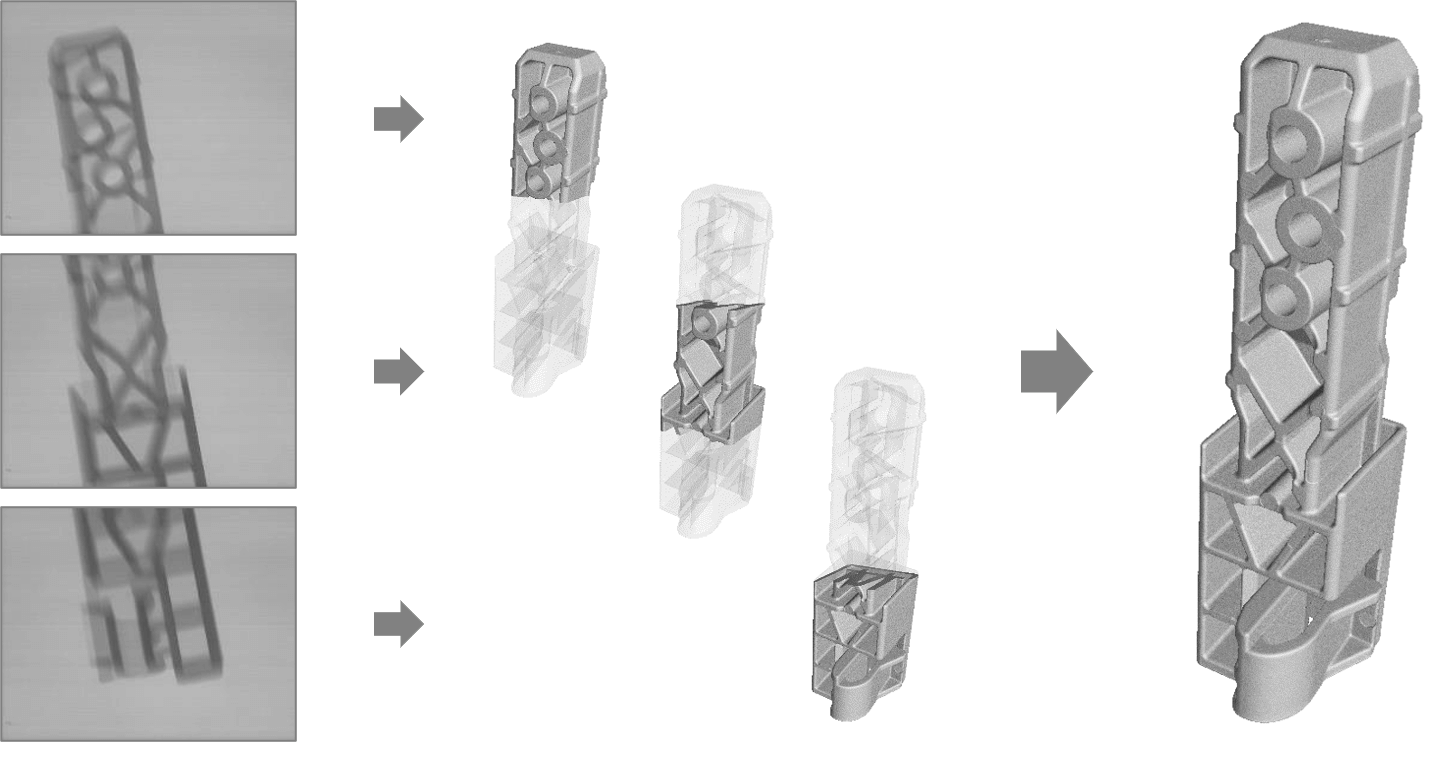

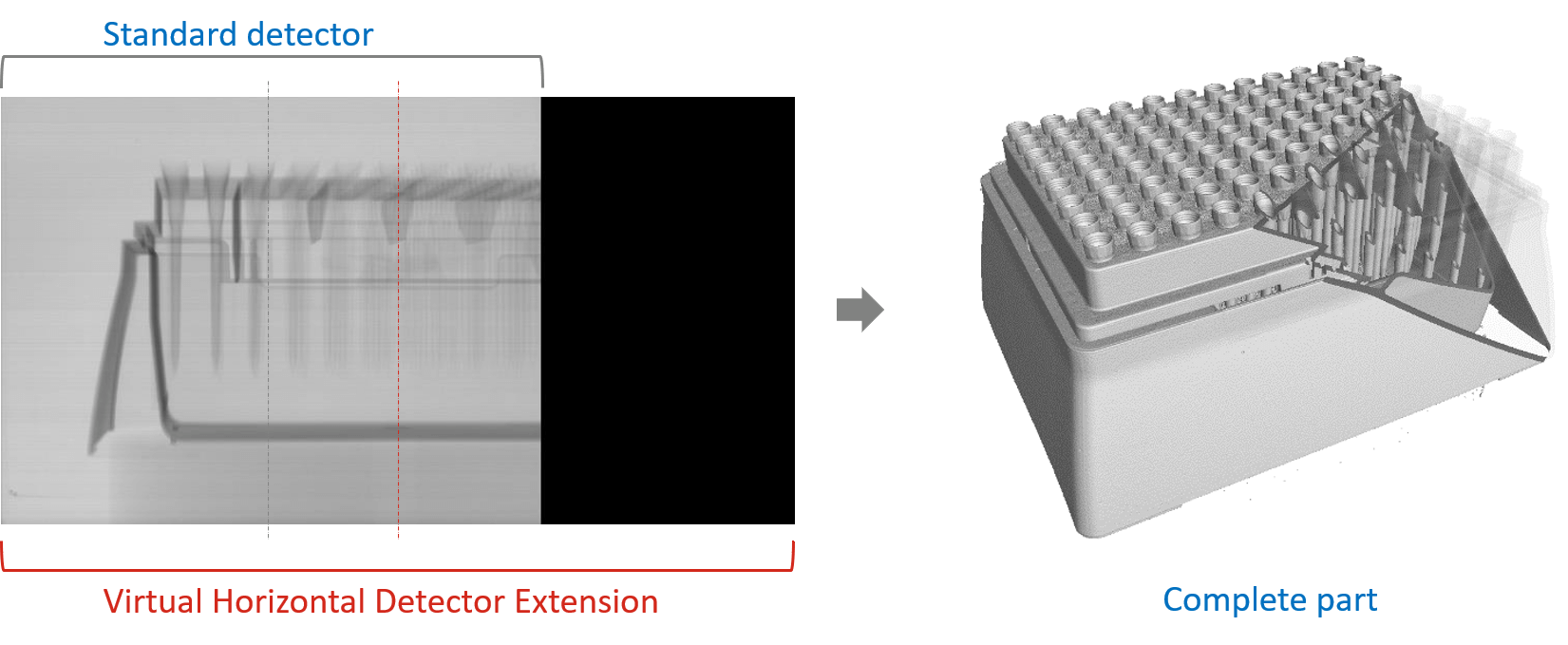

Extension of measurement range

The third generation new ZEISS METROTOM 800&1500

Future oriented quality control today

ZEISS INDUSTRY CT-ZEISS METROTOM 800&1500

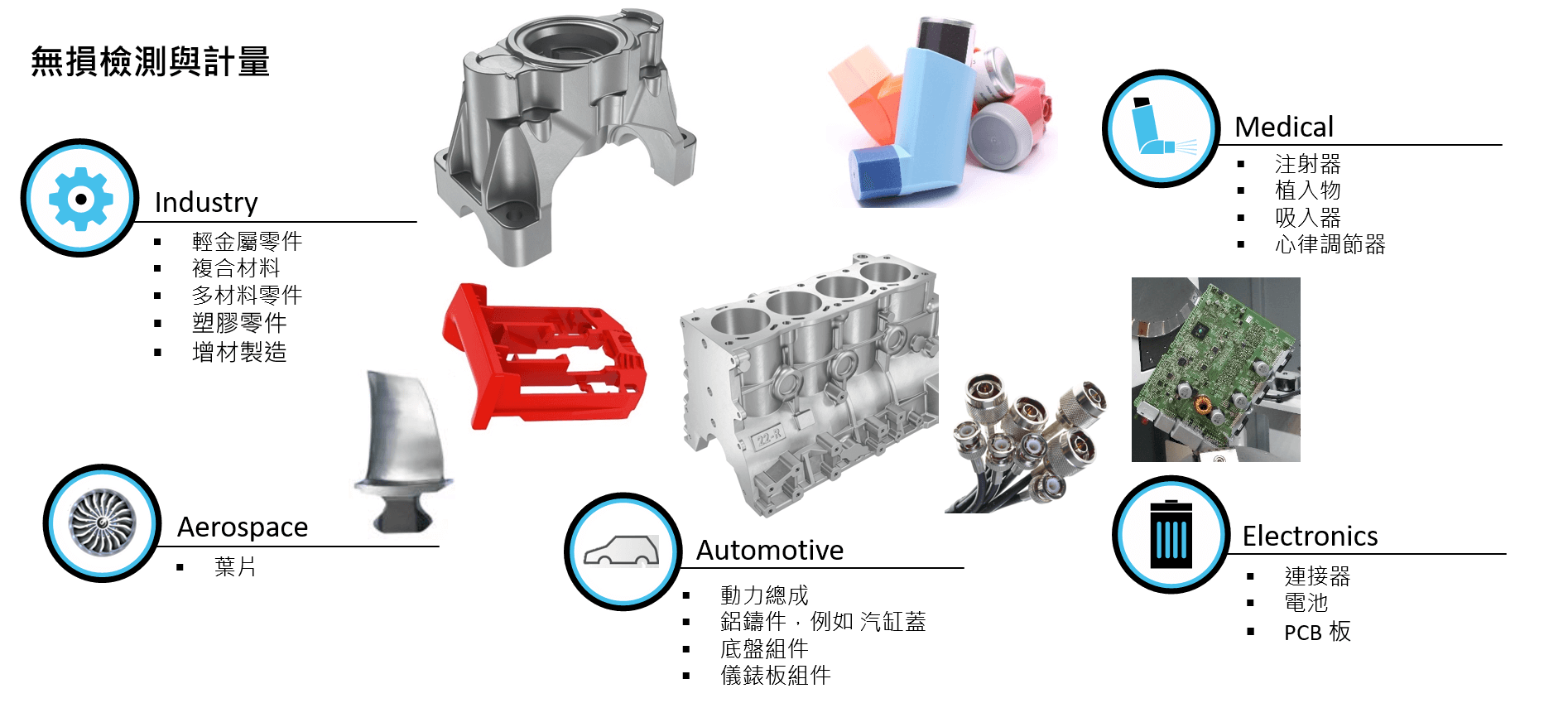

application