ZEISS MMZ M

Meet the most demanding precision requirements

Bridge CMM for Complex Workpieces

ZEISS MMZ M characteristic

Efficient and high-precision measurement

-

Resists harsh environmental conditions to minimize the need for measurement chambers -

Large bearing clearance and stable bridge design enable excellent scanning performance -

REACH CFX 3 MMZ probe extension rod for measuring very deep drilling holes (1200mm)

Low infrastructure cost

-

Compared with the measuring range, it has the smallest floor area, thus minimizing the space required -

Minimize infrastructure requirements to reduce infrastructure costs -

Articulated probe base with measuring needle can maximize flexibility and reduce cost

Ergonomic calibration

-

Full view of measurement range -

The walk-in measurement area enables effective analysis directly on the workpiece -

The mobile data station is suitable for direct programming on the workpiece

Forward looking, high quality

-

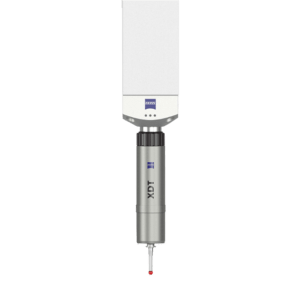

ZEISS VAST navigator probe system can quickly calibrate, scan and improve accuracy -

ZEISS VAST performance can improve measurement output

Options

main performance

Machine technology

Compatible sensors: