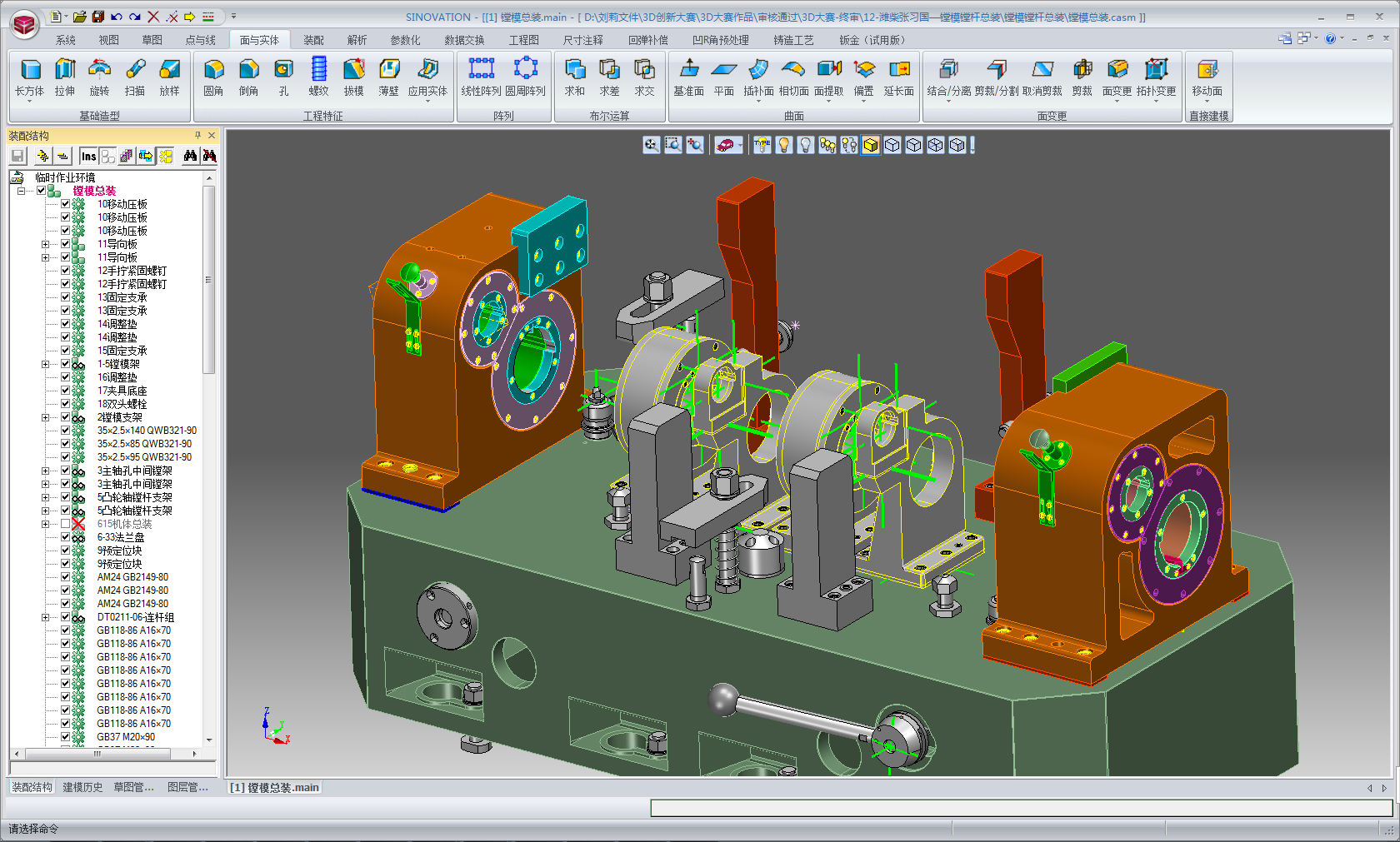

Stamping die design and manufacturing

Solution

Efficient process design

-

Provide efficient digital analog processing function, which can carry out full parametric design, whole process aided design and real-time evaluation for the model, and reduce rework -

Full parametric modeling, easy to edit and modify, fast digital analog preprocessing function, shorten the time of model modification -

In DL stage, problems such as conveying, waste sliding and standard parts configuration can be detected to ensure that the design will not be reworked

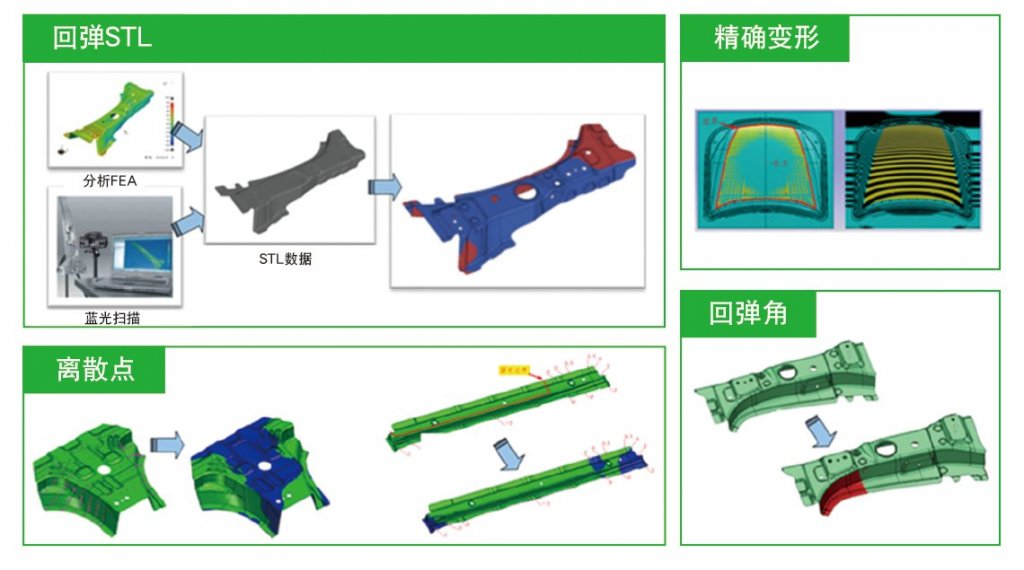

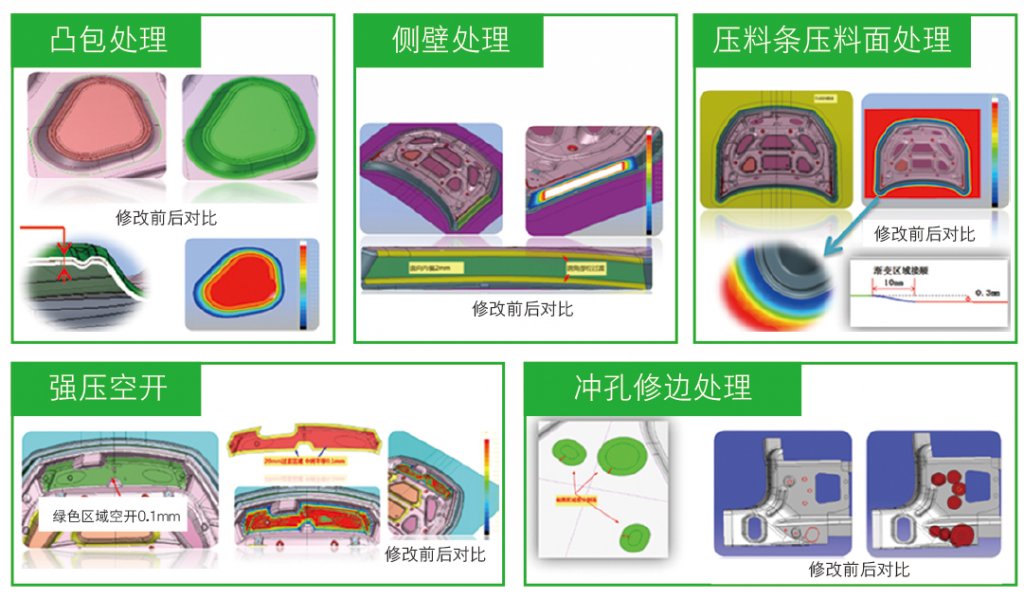

Fine processing of die surface and springback compensation

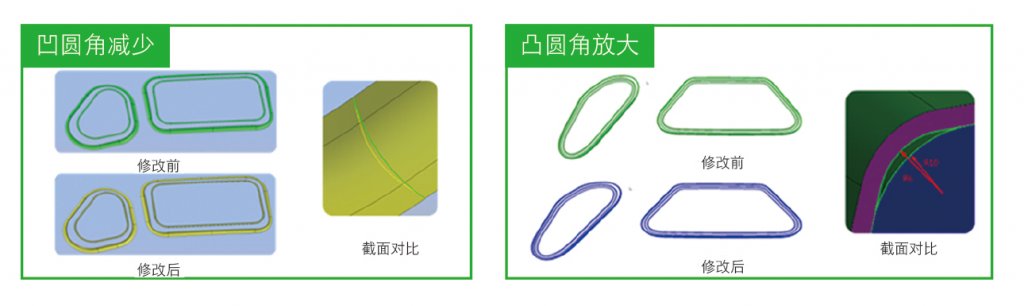

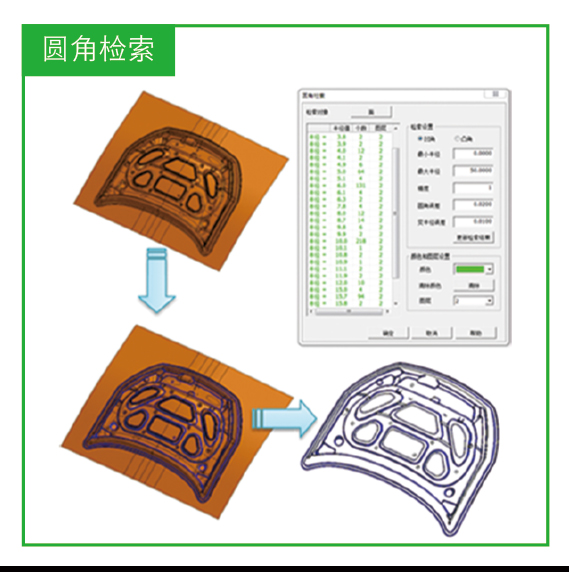

Fine processing of die surface; fillet avoidance

Fine processing of die surface and clearance design

-

Special design tool, which can quickly adjust the mold surface -

Automatically generate offset surfaces and high-quality blend surfaces, reducing manual operations -

Improve the degree of numerical control, shorten the bench worker's grinding time, and reduce errors