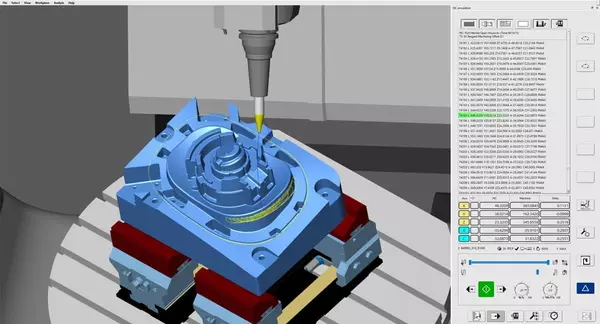

Provide the best NC program for your multi axis machine tool at any time

hyperMILL® VIRTUAL Machining Optimizer

features

-

Automatically select solutions -

Automatically link any steps from 2D to 5 axes -

If there are axis restrictions, change to another solution -

Simpler programming

-

Preferred Solution -

Safety plane calculation

-

Optimizes movement if there is a risk of collision -

Optimize the use of machine tools with limited functions

-

Auto link motion -

Automatically maintain safety clearance for transition movement -

Shorten auxiliary processing time -

Optimize machine running time

Auto link motion

-

The machine movement and available control functions have been optimized. -

The machine tool components can be protected while realizing the natural motion control at the highest speed. -

Safety collision check movement -

No need to increase the workload of programmers

Automatically select solutions

-

Check each step individually -

In case of collision and machining area error, alternative solutions can be searched automatically -

If necessary, the work order can be split and output in the alternative direction -

Maximum reliability and productivity