Industry 4.0: From CAM to Machine Tools

Safe generation, optimization and simulation of NC code

hyperMILL® VIRTUAL Machining Center

The cornerstone of NC code

hyperMILL® VIRTUAL Machining Center

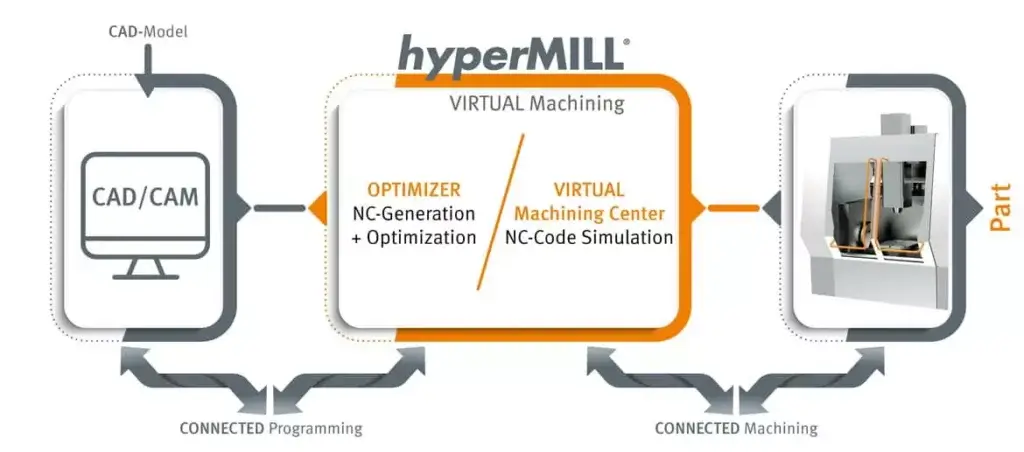

hyperMILL® VIRTUAL Machining Optimizer

hyperMILL® CONNECTED Machining

hyperMILL® BEST FIT

NC code generation and simulation

“ hyper MILL ® With VIRTUAL Machining, we can map all processing steps of CNC manufacturing in the software to ensure maximum security and consistency. "

For our hyperMILL ® Interested in VIRTUAL Machining solutions?

Detailed functions and modules

Immediately use hyperMILL in your manufacturing process ®!

-

NC code simulation -

Maximum security -

Set time faster -

Quick collision check

-

Shorten auxiliary processing time -

Shorten programming time -

Quick Align Components -

Reduce the burden of employees