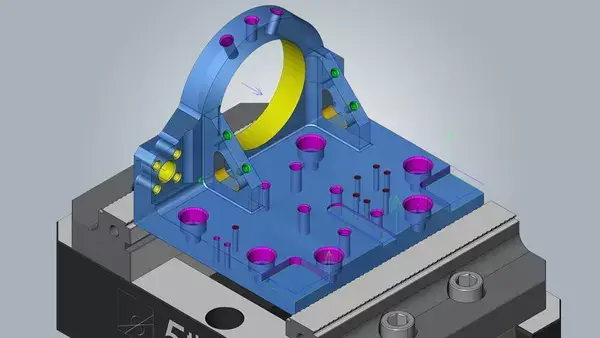

Automatic generation of NC program

CAD/CAM Automation

advantage

Shorter programming time

Reliable and fast recognition of machining features

Machining knowledge stored in macro

Semi automated or fully automated processes

CAD/CAM Automation It can make great contributions to enhancing competitiveness, improving production efficiency and enhancing process safety.

Key to automation

Feature technology

Macro technology

VIRTUAL Tool tool database

hyperMILL® AUTOMATION Center

Tools designed for successful automation