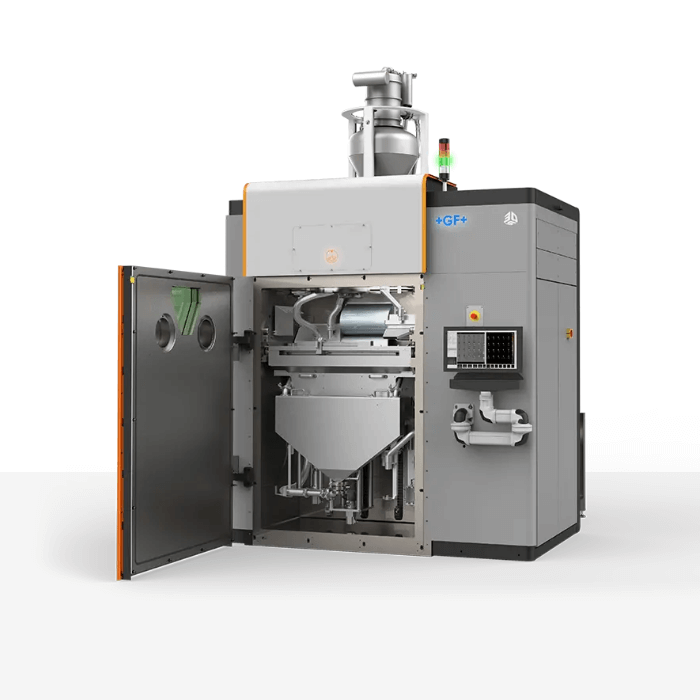

Metal 3D printer

Expandable, high-quality metal additive manufacturing, integrated powder management

Integrated material management

High quality, high throughput, low overall acquisition cost

FEATURES

application

-

Weight reduction/lightweight design -

Orthopaedic and spinal implants

technical specifications

-

Direct Metal Printing (DMP) technology -

Built in automated powder management -

Modeling volume: (W x D x H): 275 x 275 x 420 mm (10.82 x 10.82 x 16.54 inches) – height including formwork -

Unique vacuum chamber concept (O two < 25ppm) -

Special for material type -

Rapid bi-directional powder deposition -

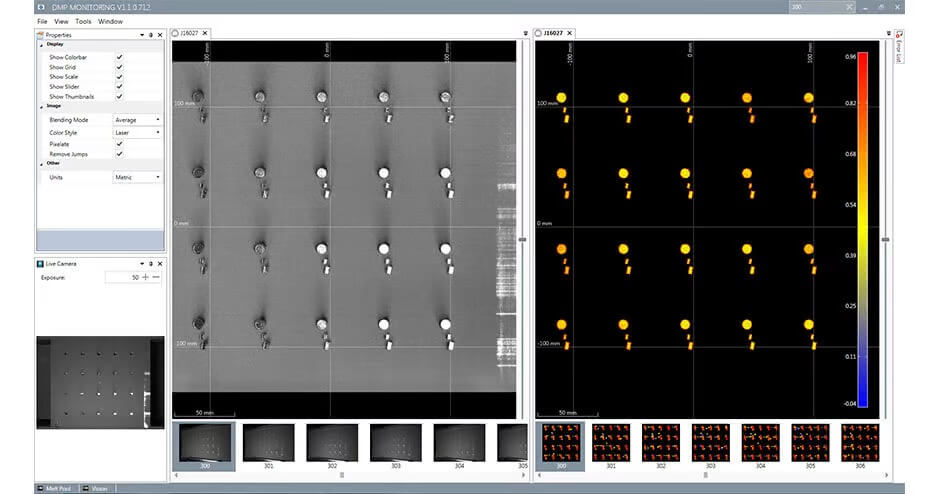

Improve productivity and management through a central DMP server -

Using DMP monitoring Real time process monitoring

advantage

-

Simplified assembly -

Reduce the number of parts -

Conformal cooling -

Improved fluid flow -

Conformal lattice -

Optimize topology construction -

Mass customization

High quality powder and process management

Designed to expand production

The unique vacuum chamber concept can ensure ultra-high component quality

Fast, high-quality performance

500000 challenging parts printed annually