GOM Probe

GOM Probe

Innovative technology

GOM Probe

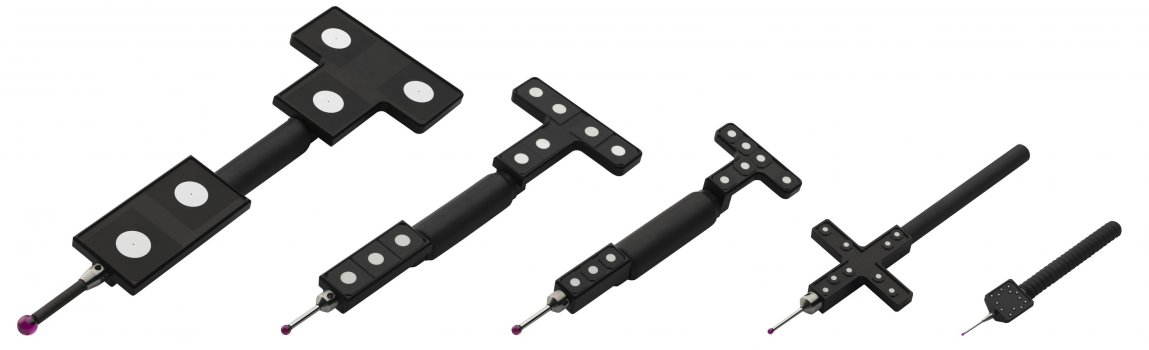

characteristic

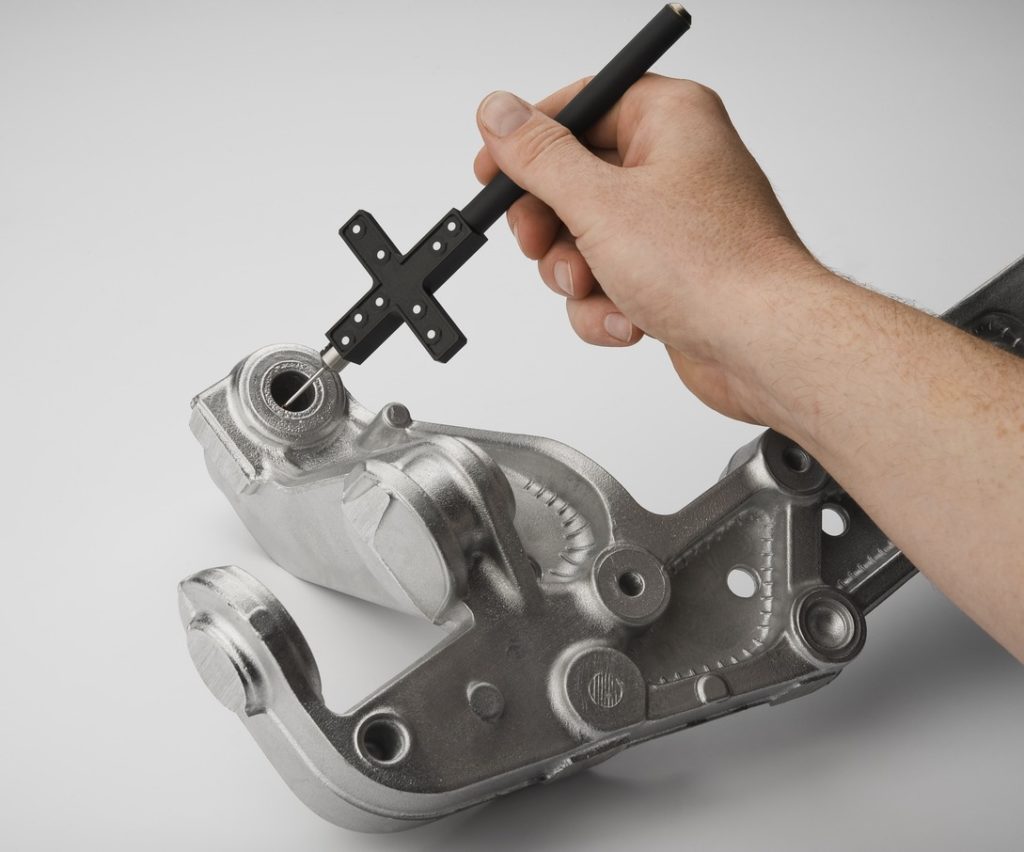

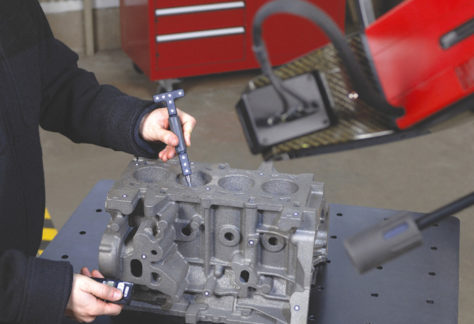

Perfect combination of scanning and probing measurement

Supporting hardware and software

Measurement of small to large objects

on-line measurement