ZEISS Industrial CT - METROM 6 scout

Metrology CT (GOM CT)

New standard of ZEISS Industrial CT-3D scanning X-Ray penetrating

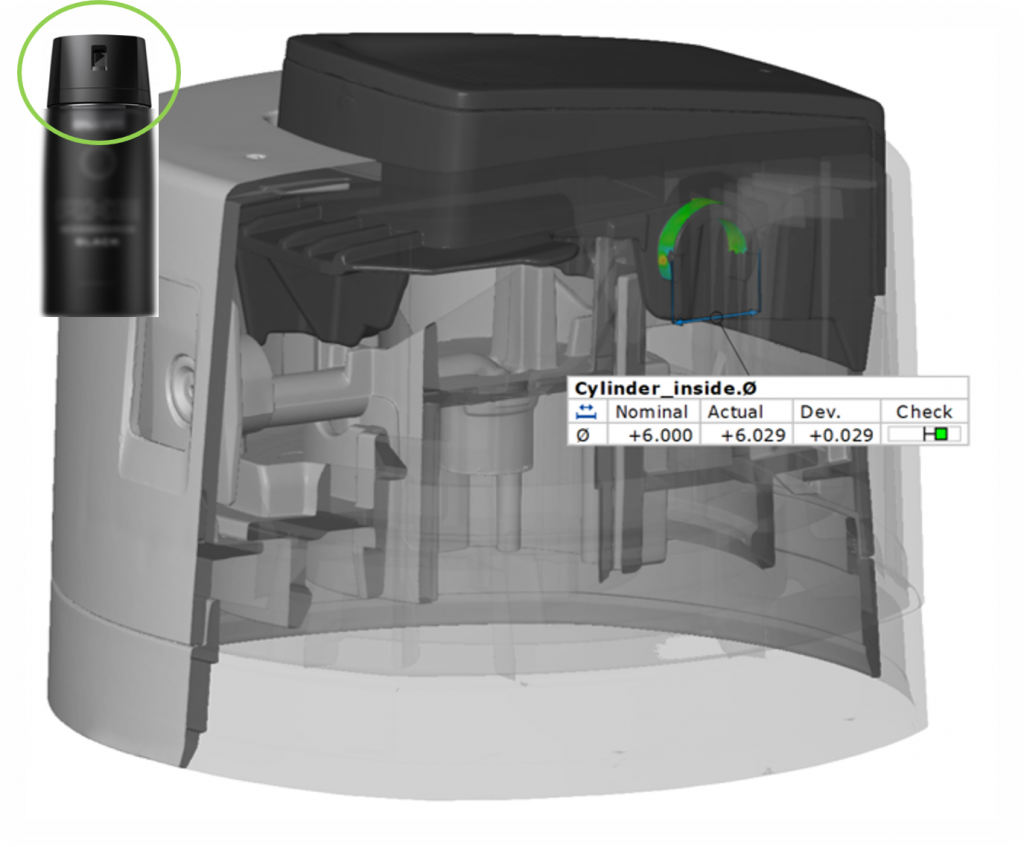

Industrial 3D computed tomography is to restore 3D digital data by combining the characteristics of X-ray penetrable objects with image reconstruction technology. The biggest advantage of using industrial CT is non-destructive testing. The internal condition of the workpiece can be seen without surface treatment or damage. There is no dead angle in scanning, and it is good at analyzing complex structures. It includes dimension measurement, internal assembly problems, and whether there are defects in materials. In the past, the workpiece can only be cut open for inspection, but the action of "cutting" will cause other problems and doubts. Now 3D digital data can be obtained by scanning industrial CT equipment, and perspective view and any section can be checked directly on the computer, so that the size can be accurately measured.

ZEISS CT-METROTOM 6 scout (GOM CT)

Innovative technology

high resolution

high-precision

Very high resolution

Integrated professional software

ZEISS CT-METROTOM 6 scout (GOM CT)

characteristic

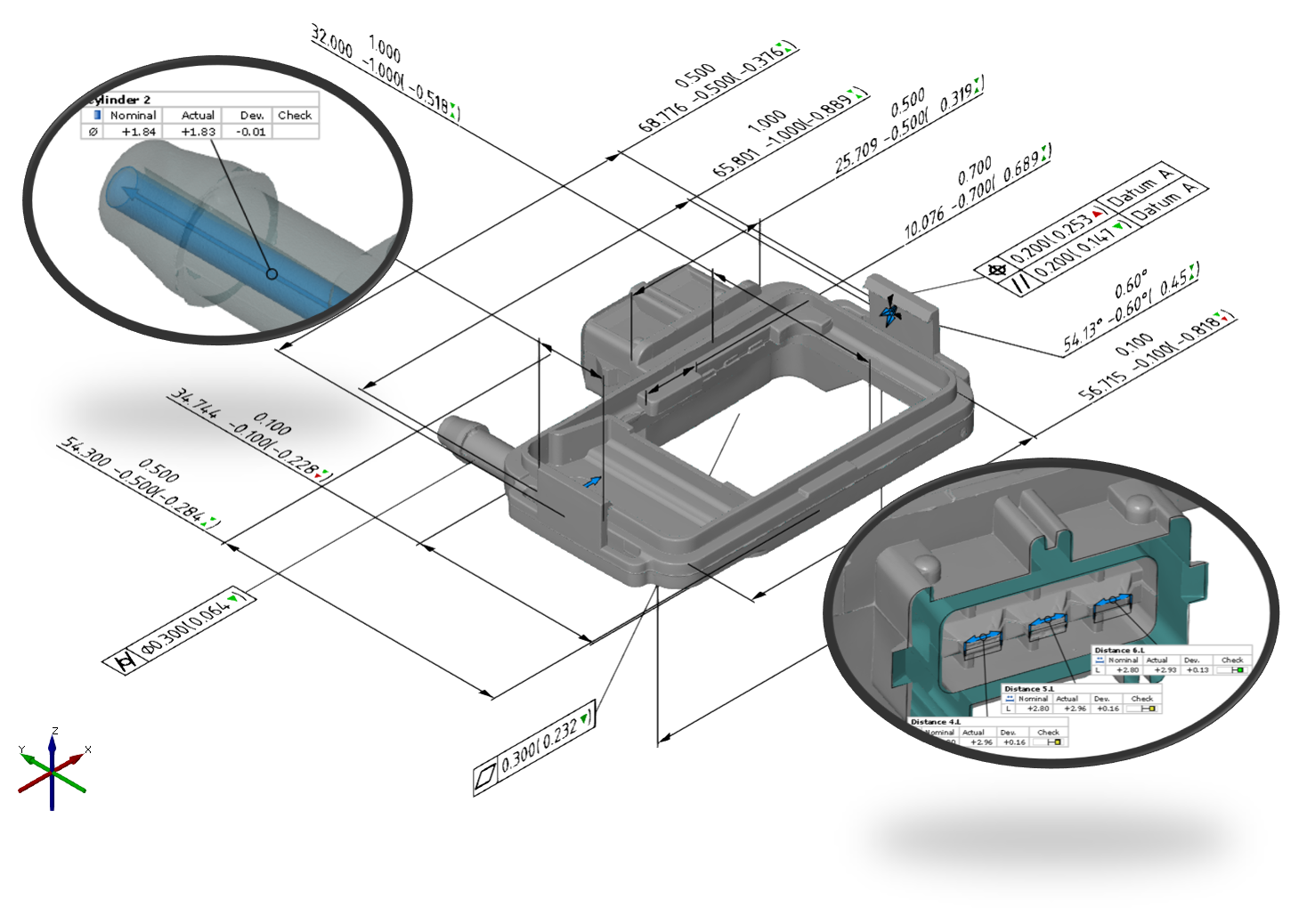

Measurement application

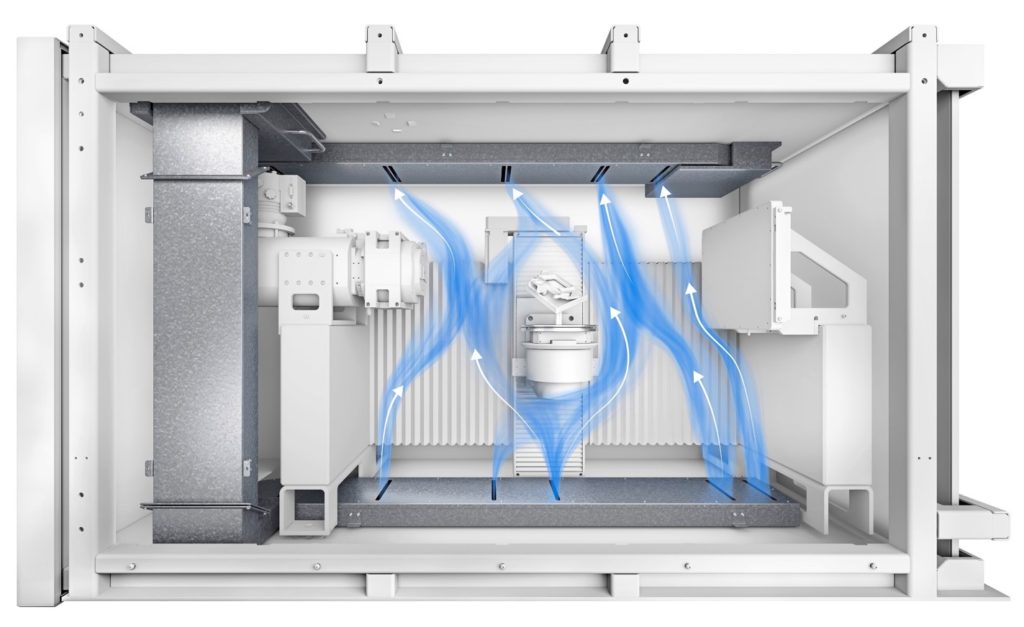

Temperature balance system

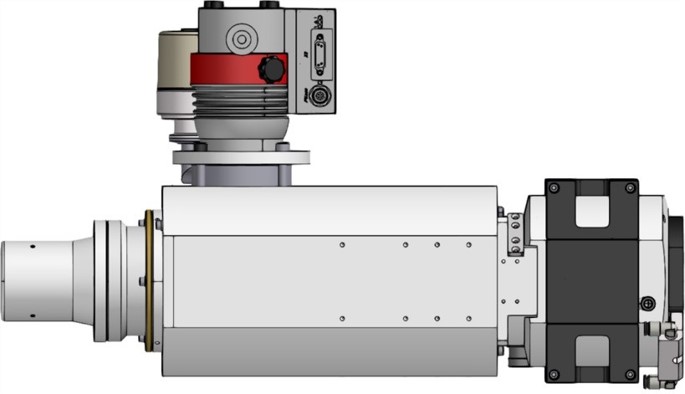

Open X-ray tube

ZEISS CT-METROTOM 6 scout (GOM CT)

Advantages of

Expose details that cannot be displayed by other measuring systems

High precision effect

Easily find the best positioning of parts

ZEISS Industrial CT * METROTOM 6 scout (GOM CT)

Automation solutions for

ZEISS CT-METROTOM 6 scout (GOM CT)

application

Metrology precision dimension measurement

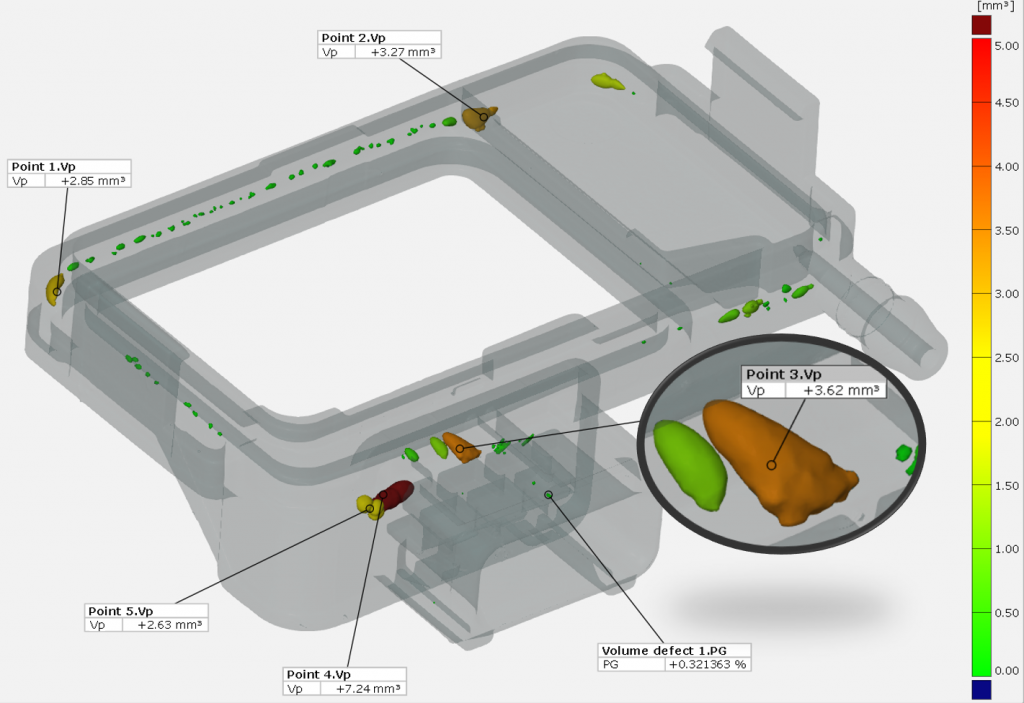

Defect Analysis

Assembly analysis

Application of Wax and Ceramic Core in CT Scanning

Application case of LEGO using CT batch scanning