ATOS Capsule

ATOS Capsule

Innovative technology

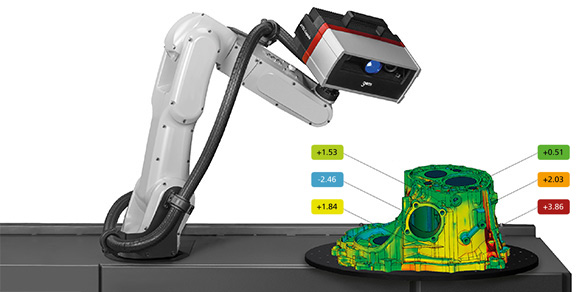

monitoring system

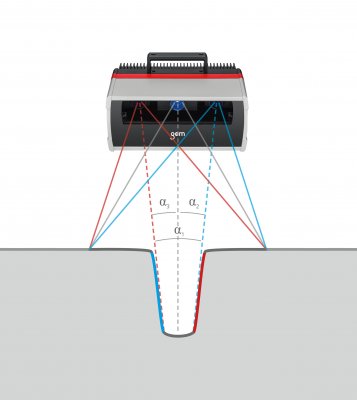

Triple scanning technology

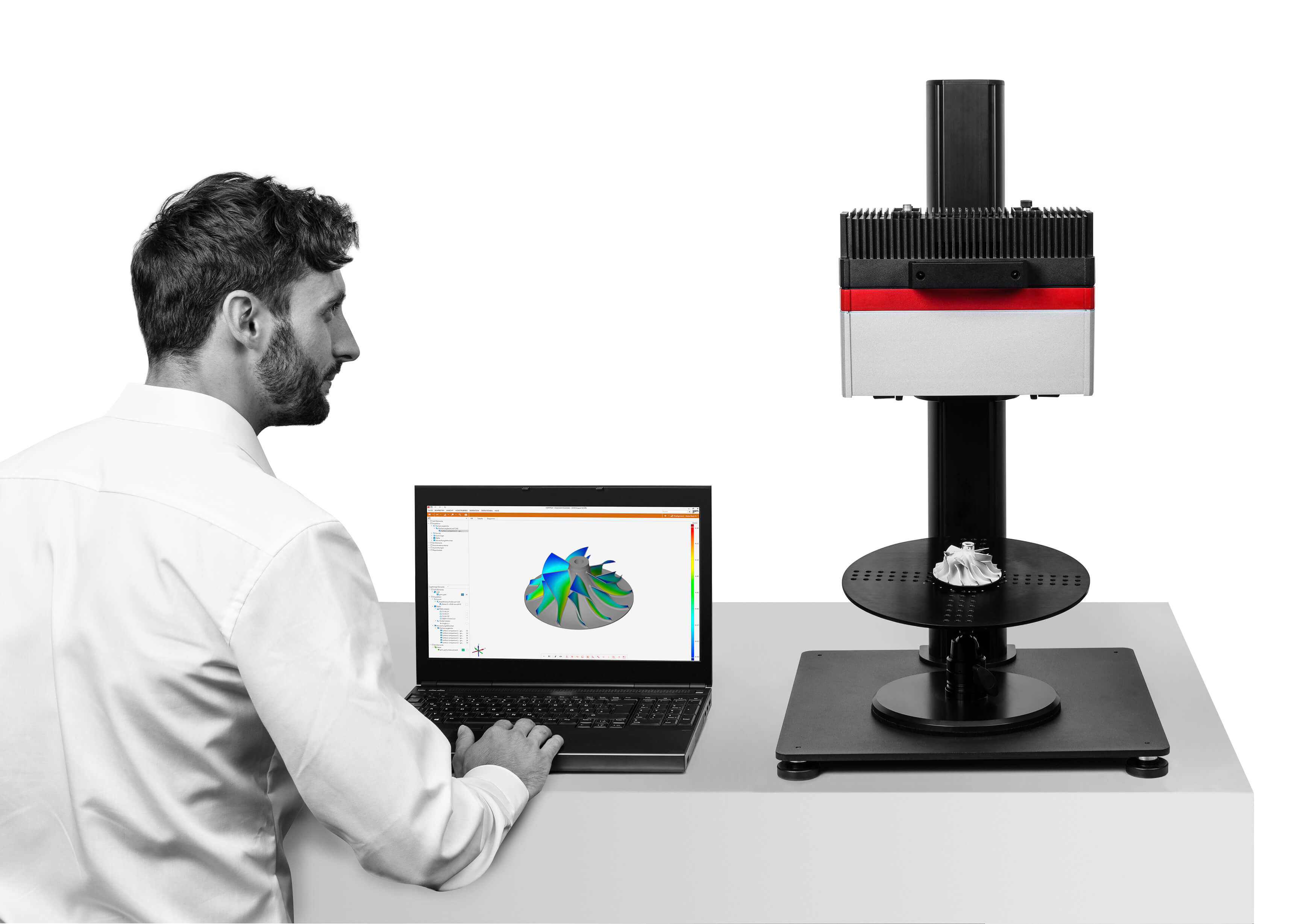

High speed scanning

High precision scanning

ATOS Capsule

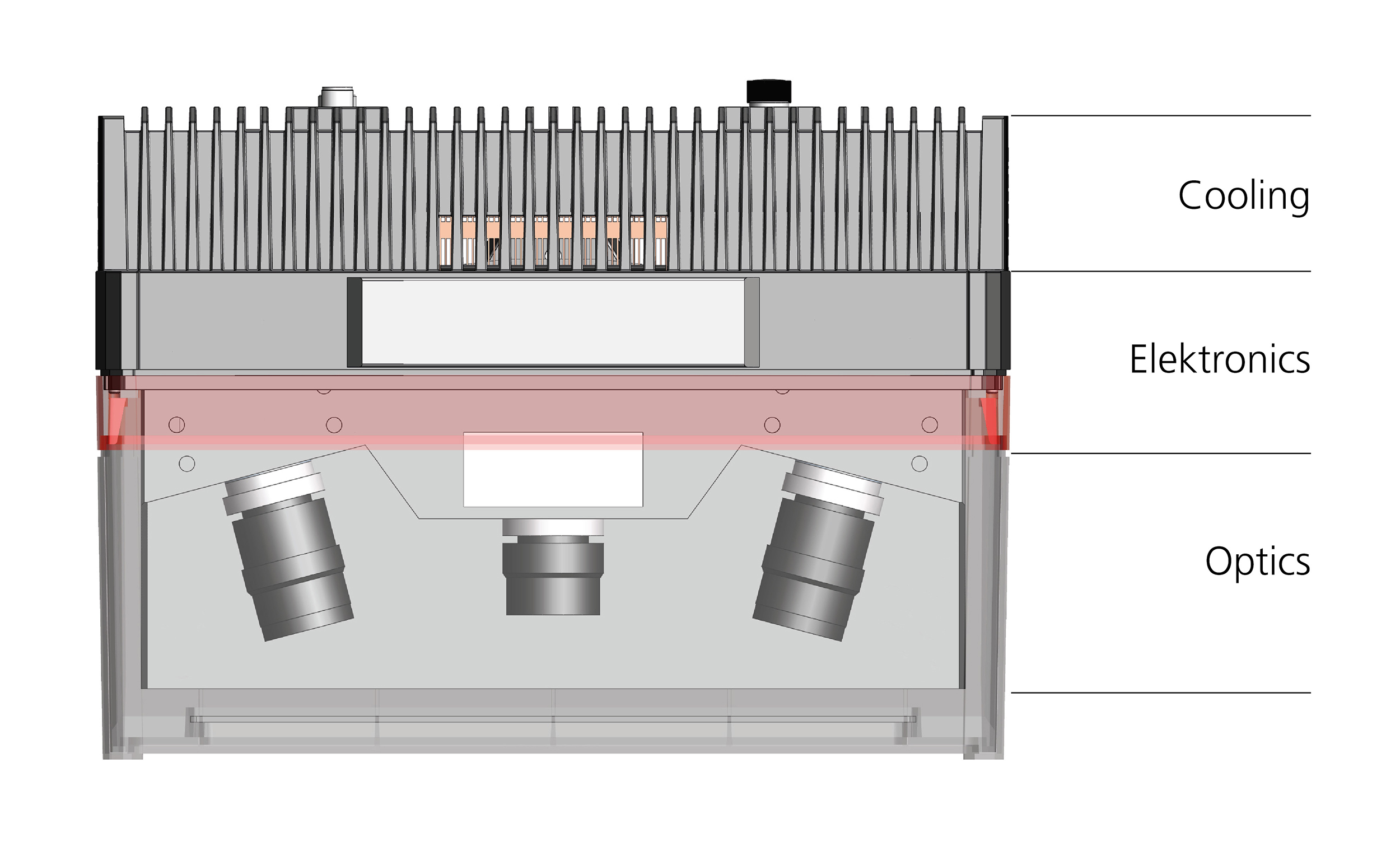

characteristic

Blue ray technology

High speed and high precision

Triple scanning technology

Self monitoring system

High rigidity and high stability

ATOS Capsule

application