ATOS 5 for Airfoil

ATOS 5 for Airfoil

Innovative technology of 3D scanner

Optimized working distance

high stability

Unique software functions

ATOS 5 for Airfoil 3D scanner

characteristic

Automatic scanning with ATOS 5 for Airfoil

High speed scanning technology

High data quality improves inspection efficiency

Accelerate the work process

Achieve high data quality

ATOS 5 for Airfoil

3D scanner blade detection function

Airfoil detection function

ZEISS software has a complete set of airfoil detection functions. The inspection principle includes standard options and customizable options to meet the requirements of different engineering standards and airfoil drawing types. User defined inspection principles (UDIP) can carry out rapid, standardized and efficient inspection of airfoil parts.

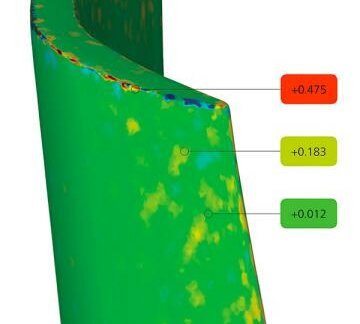

Surface Comparison

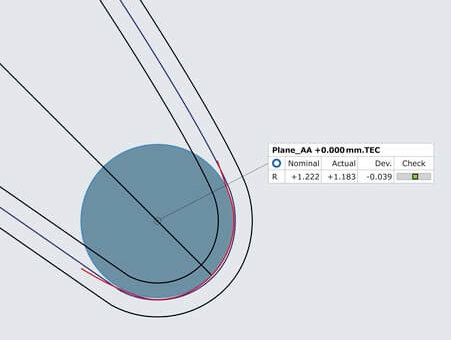

Edge points and edge circles

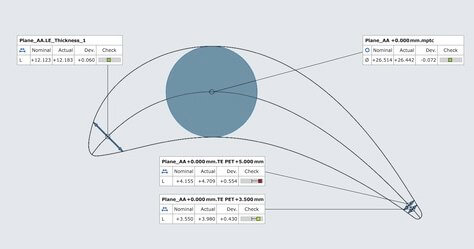

Thickness inspection

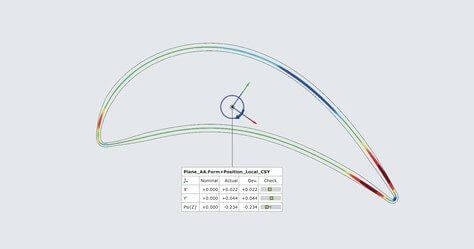

Shape and position detection

Effective analysis tools

ZEISS INSPECT provides one-stop service

ATOS 5 –

Blue ray 3D scanner series

ATOS 5 for Airfoil

Precise scanning of tiny details of parts

ATOS 5

High speed 3D scanning system