ProJet MJP 2500 Series High precision 3D printer

High quality, fast printing speed and simple use

FEATURES

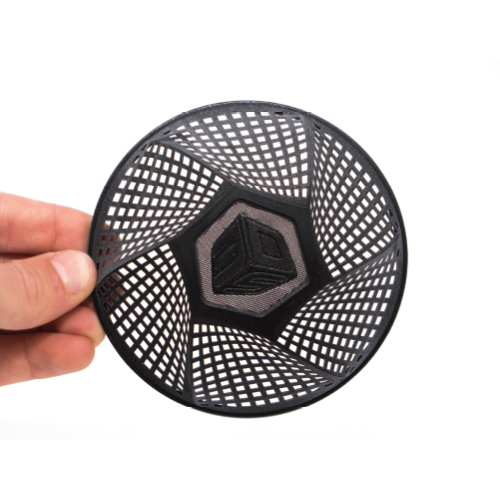

High precision 3D printer

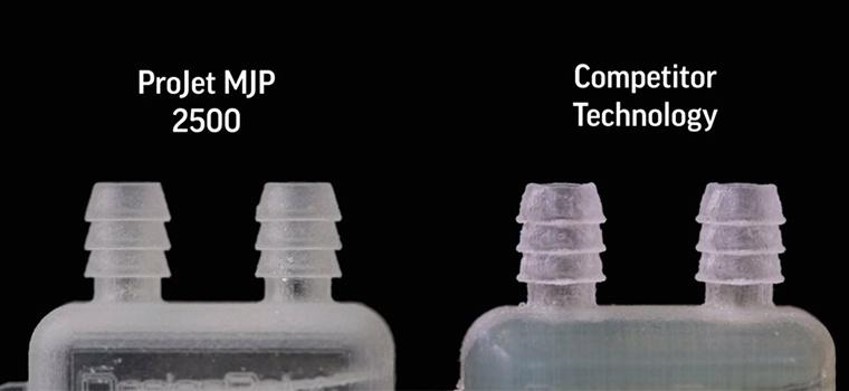

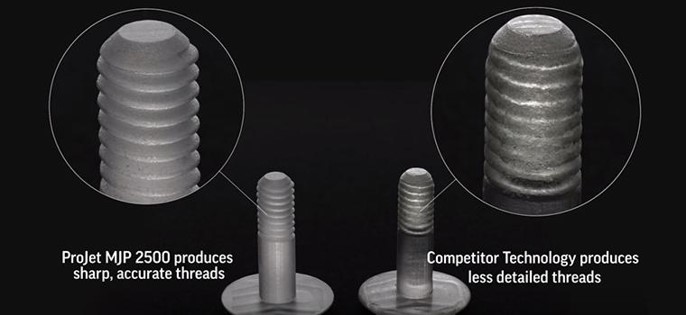

Professional quality

High precision 3D printer

speed

High precision 3D printer

simple

Tech Specs