ProX SLS 6100

Parts prototype easy printing, high throughput, fully automatic material processing

Production grade materials

Production grade materials

High quality production, prototype pricing

Excellent component quality at high throughput

-

Optimum surface finish -

Highest resolution and edge sharpness -

High precision and repeatability -

Uniform Part Attributes

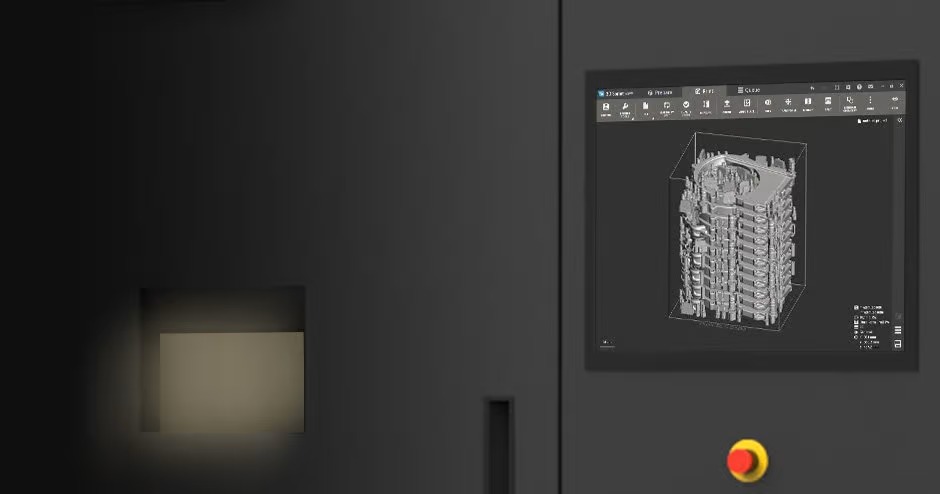

Improve workflow with 3D Sprint

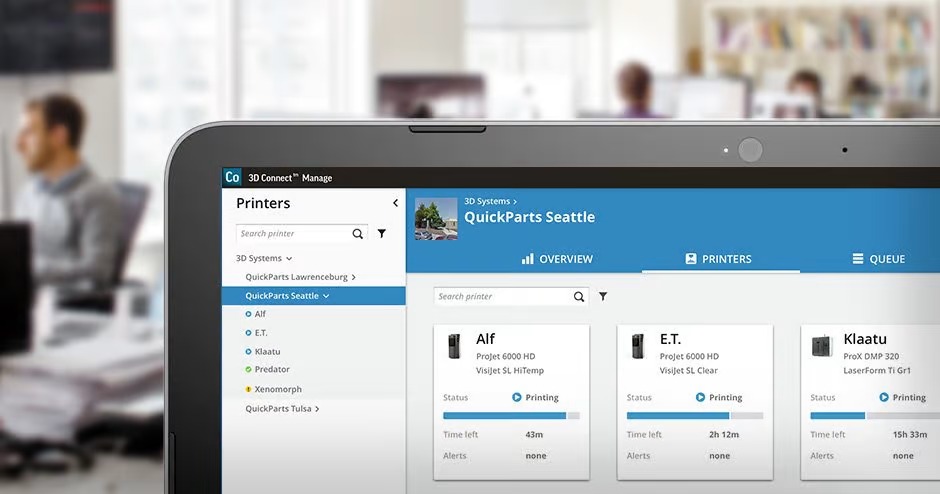

Maximize productivity with 3D Connect

FEATURES

application

-

Impact and high temperature resistant parts -

Baffle/Enclosure/Enclosure -

Fixtures and fixtures -

Lightweight production parts -

Knobs, handles and other instrument panel/internal components -

Parts with snap connection and movable hinge -

Mechanical components -

Complex pipe fittings

advantage

-

Faster manufacturing of powerful end use components and functional prototypes -

Easy printing of various designs without the need for supporting structures or post-processing -

Integrated solutions that provide expert application support -

Fully automated material processing, releasing valuable resources -

Simplify workflow with automated production tools -

Reduce cost of ownership with high throughput and material efficiency -

The smoothest surface finish, highest resolution and edge sharpness, leading all other SLS systems

technical specifications

-

Selective Laser Sintering (SLS) Technology -

Maximum modeling package capacity (W x D x H): 15 x 13 x 18 inches (381 x 330 x 460 mm) -

Production grade nylon 11, nylon 12 and various reinforcement materials -

Consistent mechanical properties -

2.7 High production speed in category l per hour -

Streamlined production control, including 3D Sprint ™ Integrated additive manufacturing software, fully automatic powder processing and optional 3D Connect function -

Automatic 3D part nesting -

Maximize production and density