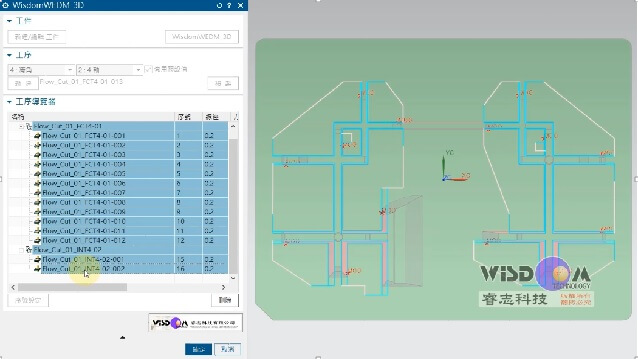

Development of wire cutting software in NX CAD environment

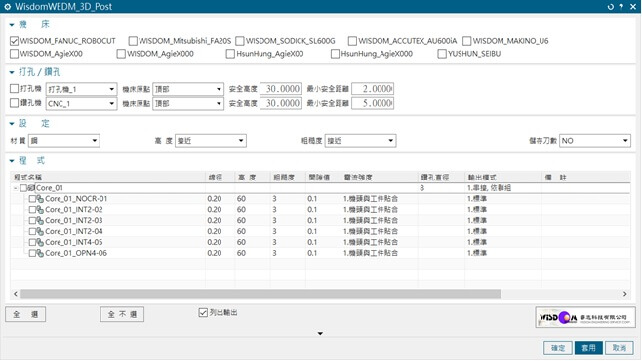

Wire cutting brands and machines provide complete solutions

Post processing output is applicable to various EDM machines

-

All Agie Charles EDM machines are supported. -

Support AgieVision script file format (SBR, SBL and ISO) -

Support GF script file format (MJB)

-

West (SEIBU) -

Sodick -

Makino -

Fanuc -

Mitsubishi -

…

-

ACCUTEX -

CHMER -

…

Benefits of WTC WEDM intelligent wire cutting

-

Complex curve (SPLINE) does not need to be sorted -

It is easy to program the upper and lower profile path based on the solid model -

Automatic identification of threading point crosscutting in path generation -

Wire cutting parameters are linked to the database, and cutting conditions are fed back -

Automatic programming of entity feature identification

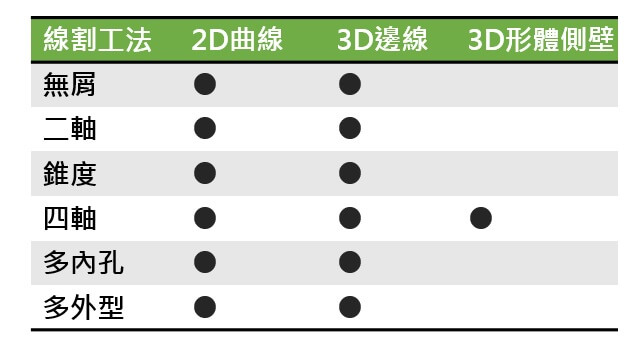

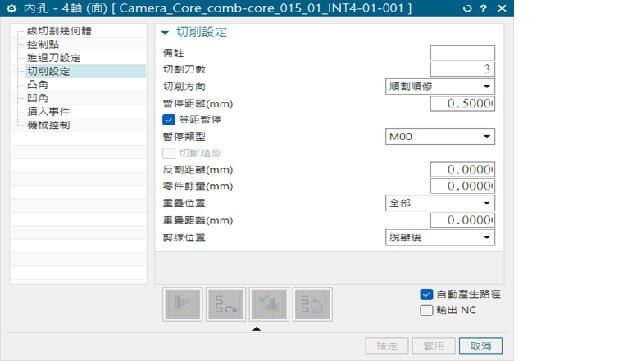

Cutting strategy

-

No Core -

Internal Trim -

LExternal Trim -

LOpen Profile

-

Internal Trim -

LExternal Trim -

LOpen Profile

-

Internal Trim -

LExternal Trim -

LOpen Profile

-

No Core -

L Internal Trim

-

External Trim

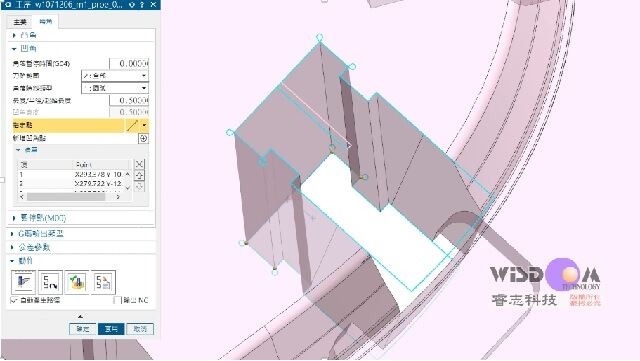

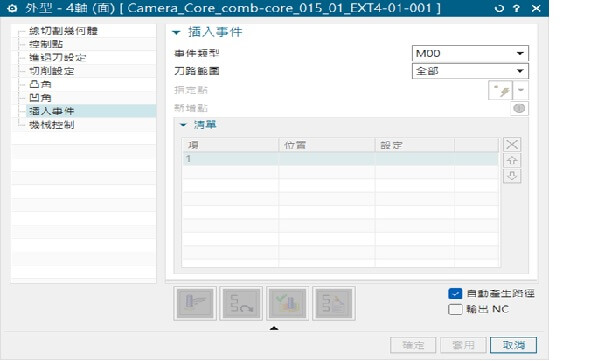

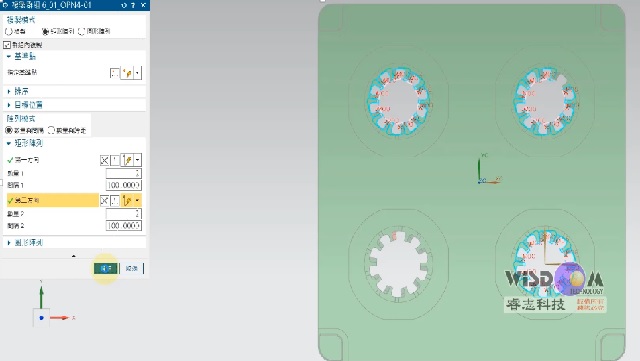

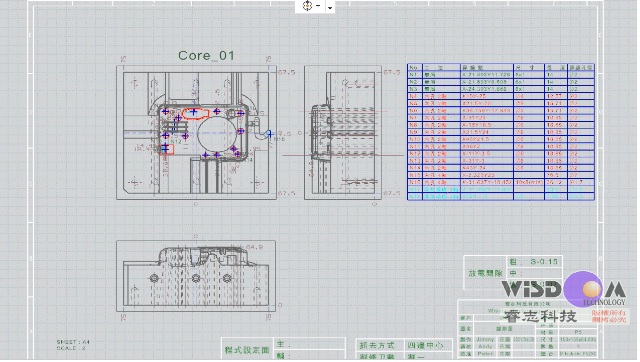

Important features of WTC WEDM intelligent wire cutting

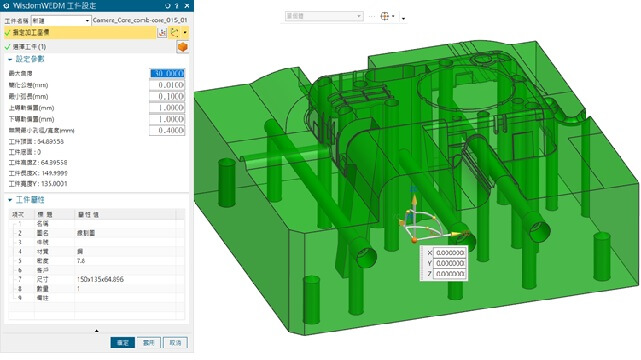

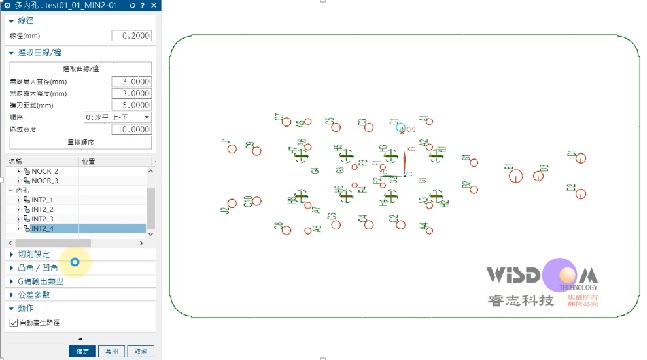

Workpiece setting

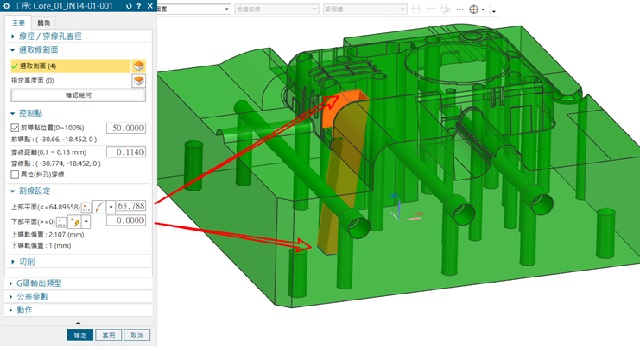

Cutting geometry selection

Model selection and program surface setting

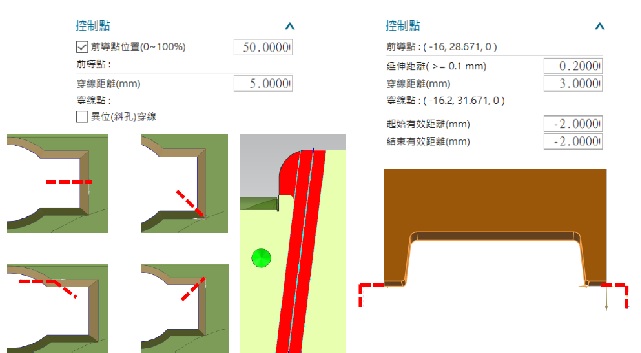

Search for threading points

Cutting function

Convex corner path processing

Concave corner path processing

Insert Event

Path copy function

Angle cleaning function

Multi bore, multi shape function

Plot characteristics

Post treatment characteristics