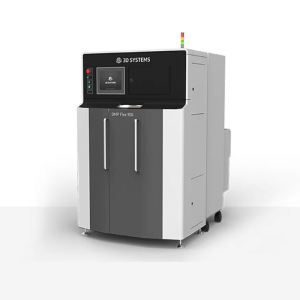

DMP Flex 100

Fast and low-cost accurate metal 3D printer

Everything you need to print

Small size

Ultra high surface finish to reduce support

Excellent precision and repeatability, the finest details, the thinnest wall thickness

Wide application of material function realization

application

-

Small and complex precision parts -

research and development -

Simplify assembly/reduce the number of parts -

Weight reduction/lightweight design -

Improved fluid flow -

Jewelry making

technical specifications

-

Direct Metal Printing (DMP) technology -

Modeling volume: (W x D x H): 100 x 100 x 90 mm (3.94x 3.94 x 3.54 inches) – height including formwork -

Surface finish quality up to 5 Ra microns (200 Ra microinches) -

High precision and repeatability -

Intuitive 3DXpert software for part setup and production -

Parameter Certified LaserForm material

advantage

-

Excellent surface finish and resolution -

Print parts that are difficult for others to print -

Minimize material waste -

From the first printing, ensure the production of high-precision parts from beginning to end -

Simple, intuitive and easy to operate workflow -

Complete solution (printers, materials, software and application support)