Cloud anytime, anywhere, efficient collaboration

In order to better manage the company's cost details and transaction accounting, Guangdong Jintuo Information Technology Co., Ltd., the local service provider of Kingdee Dongguan, will upgrade the existing commercial version to Kingdee KIS Cloud · Professional version products, help the company put the data in the cloud, and the data of each business system will form information resource, from the receipt and delivery of inventory to the delivery of sales business From the purchase of demand logistics, to the production and processing process of finished products, to the management of equipment asset life cycle, to the integration of finance, the overall resources are digitized and informationized.

At the same time, Kingdee background O&M will automatically back up the A/C set data every day, and roll save the data of the last month for customers. Users can be authorized to use it on the specified equipment and in the specified time period; The enterprise can control the A/C set data independently, and the A/C set data is managed by the enterprise, which can be backed up and downloaded, so that Guangsen can use it more confidently.

Whole process management of supply chain, cost reduction and efficiency increase

Through the production work order of Kingdee KIS Cloud Professional Edition - consumption of parts and accessories - product sales, a closed-loop road is formed to help Guangsen manage products and materials and accessories in the whole process. Kingdee Cloud Professional's purchase, warehousing, sales and production of raw materials have opened up the whole business process of the company, and used BOM and work orders to collect raw materials and semi-finished products. After the finished products are completed, they can be put into the finished product inventory for sales and delivery, which brings great convenience to the warehouse and reduces the waste of excess inventory due to the large number of raw materials and components The occurrence of inaccurate inventory data.

Business and financial integration, easy and convenient

After using the Kingdee KIS Cloud Professional version of the general ledger system, the A/R generated by the sales of goods, the A/P generated by the purchase of raw materials, employee reimbursement, etc., and the management of the entire life cycle of assets are all linked into the general ledger data; The revenue and expenditure of the whole enterprise can be fully incorporated into financial management, and various required reports can be automatically generated. The cashier accountant uses the cashier management system to generate vouchers by clicking the usual expense reimbursement expenses and fund flow, and automatically reconciles with the general ledger. The fund flow entries are clear. Through the combination of the inventory accounting module and the production management system, the weighted average method is used to calculate the average cost and sales profit of finished products, One click can show the sales profit to the boss and business personnel.

After the seamless integration of the purchase, sales, warehouse, production management system modules and the financial system, all business data will automatically generate A/R and A/P sub ledgers and summary data through the business system. One click query will enable automatic reconciliation, and the transaction balance will be clear at a glance.

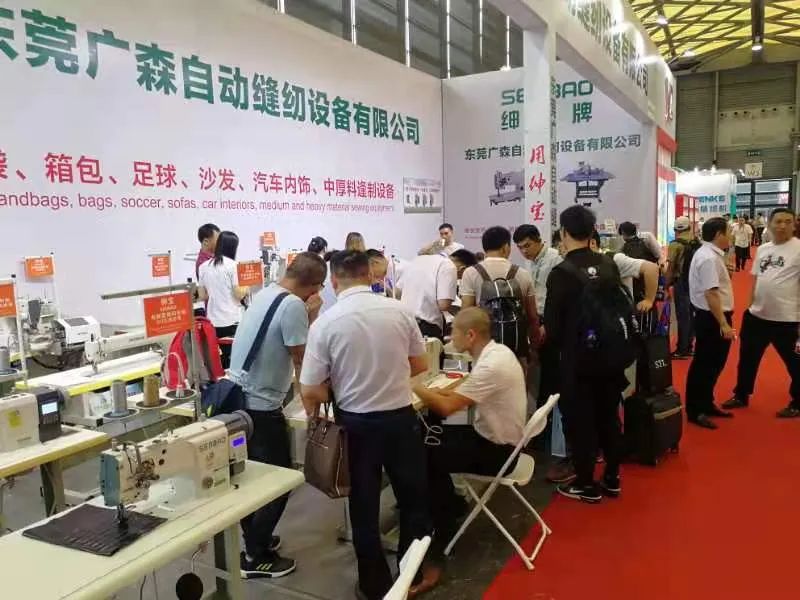

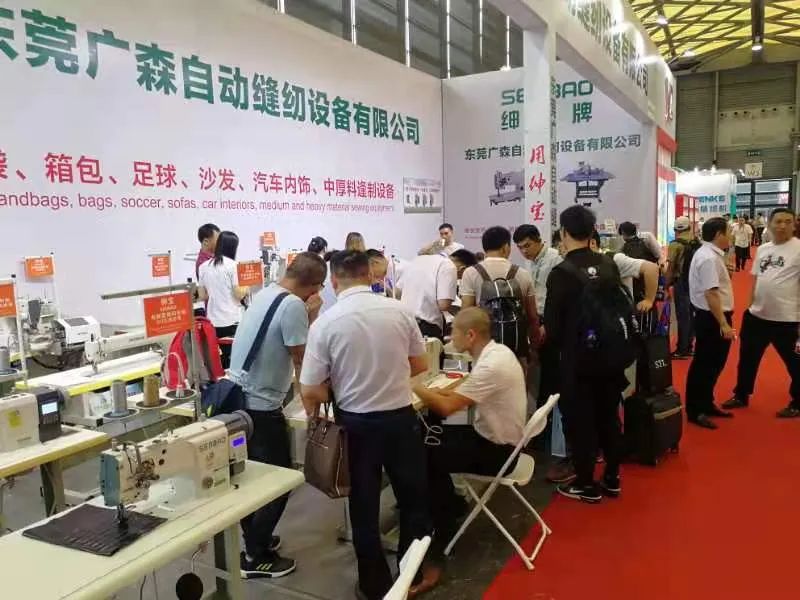

The tide of the times is rolling in. The greatest creativity often bursts from very difficult circumstances. Machines are still roaring, and starting, brilliance and transformation are the constant theme of China's industrial history. Guangsen Sewing is like a follower in the digital competition. Although the reform has made achievements, it is not the end. Their growth journey continues. Digital infrastructure will continue to broaden the boundaries and define the future.