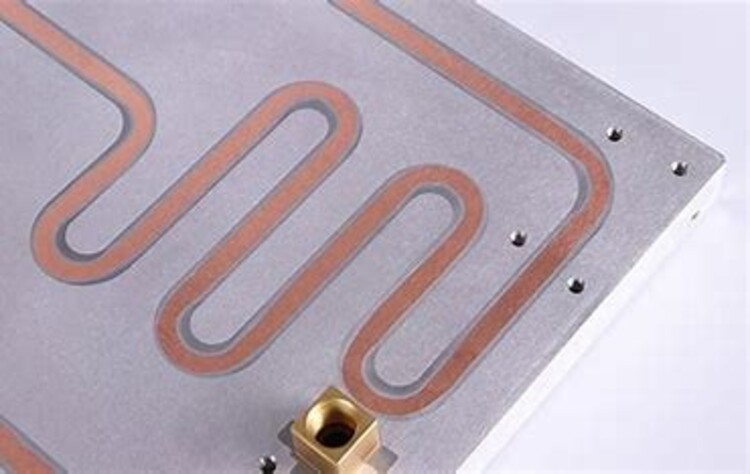

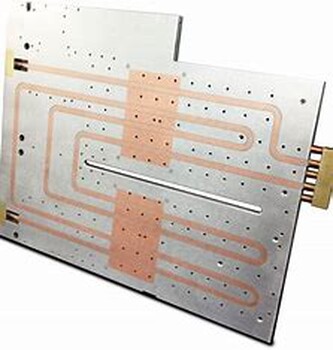

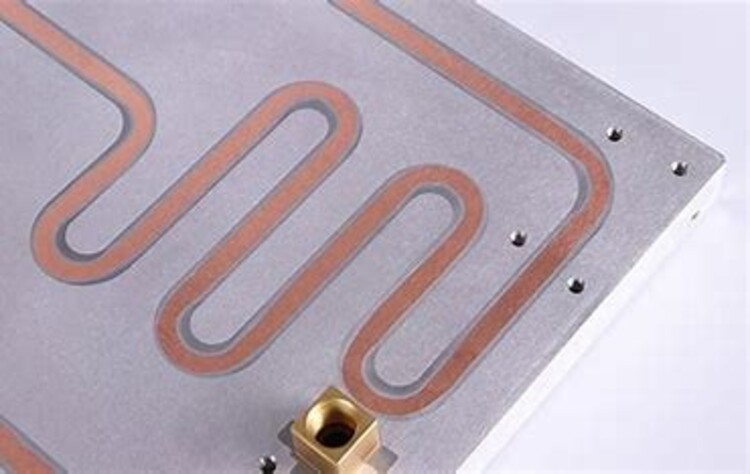

No matter which method you choose to use for precision parts processing, such as water-cooled plates, quality is the prerequisite, and grinding is also carried out on this basis. There are three kinds of machine tools involved in the grinding of precision parts in the process of precision zero machining, namely surface grinder, internal and external cylindrical grinder and tool forming grinding machine. However, no matter where the equipment is used, the occurrence of grinding deformation and grinding cracks should be strictly controlled when precision parts are processed and ground, even the micro cracks on the workpiece surface, otherwise they will gradually emerge in the subsequent work. In order to achieve this goal, the feed amount of precision parts during close grinding shall be small, the cooling during grinding shall be sufficient, the coolant medium shall be selected as far as possible, and the parts with machining allowance within 0.01mm shall be subject to constant temperature grinding as far as possible. Moreover, the grinding wheel should be carefully selected to ensure that good machining results can be obtained. When precision parts are processed and ground, the grinding wheel should be trimmed in time to keep its sharpness. When the grinding wheel is passivated, it will rub, scratch and squeeze on the workpiece surface, causing burns, micro cracks or grooves on the workpiece surface, which will significantly reduce the effectiveness of future use. For the precision machining of disc and plate parts, the surface grinder is mostly used, but for some long and thin sheet parts, the equal height sizing block should be placed under the workpiece before machining, and the workpiece should be blocked with blocks around it to prevent moving; When grinding, the feed amount of the grinding head should be small, and the front datum planes should be completed by multiple tool paths. After the front datum planes are machined on one side, this datum plane can be adsorbed on the magnetic table, thus helping to improve the flatness of most workpieces.

At the initial stage of charging, it is very important for the heating system to automatically start the temperature of the heating battery, which has become a high requirement for the sealing of the power battery case. Good sealing performance and temperature storage.

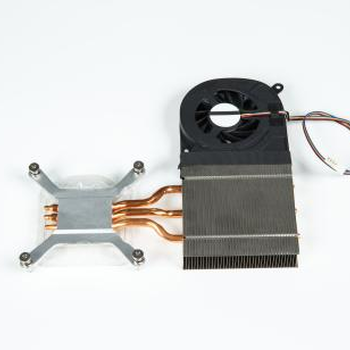

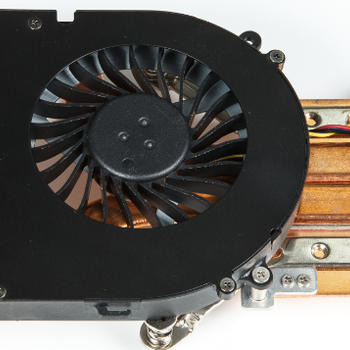

Although the water cooling products in mainland China have made rapid progress, they are still basically acceptable. The key factor is that the price is appropriate, generally between 100 and 500 yuan, which is not more expensive than air cooling radiators, and the effect is usually incomparable with expensive air cooling. However, the product is refined in processing There is still a clear gap between the rationality of supporting facilities and the safety of protection and the products of foreign regular manufacturers such as South Korea and the United States. Of course, this is related to the limitations of. After all, the liquid cooling system has not yet formed a climate, and in addition, only a few computer users play overclocking. The demand is far from reaching the level of large-scale production, So the price of the product will not change much.