Relevant introduction of polyurethane color steel plate:

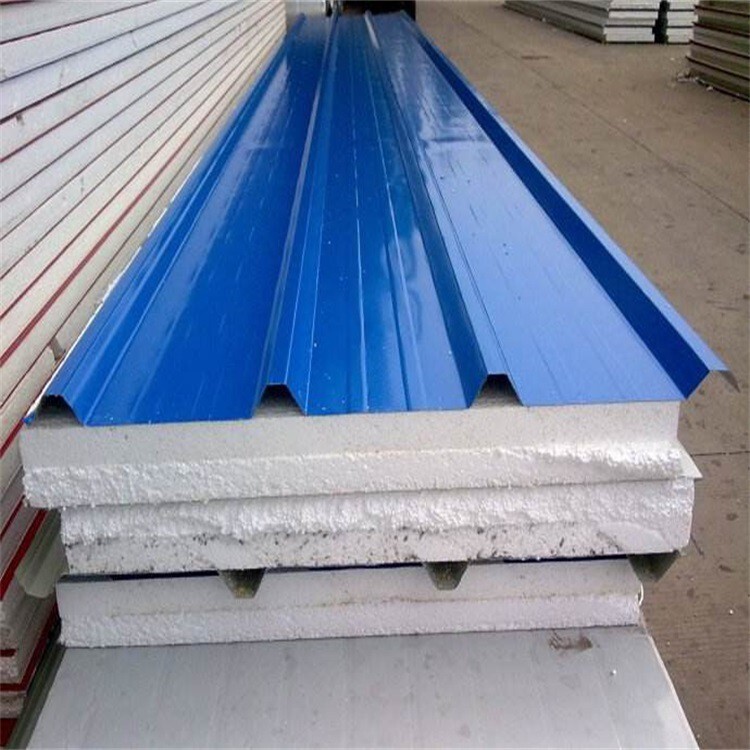

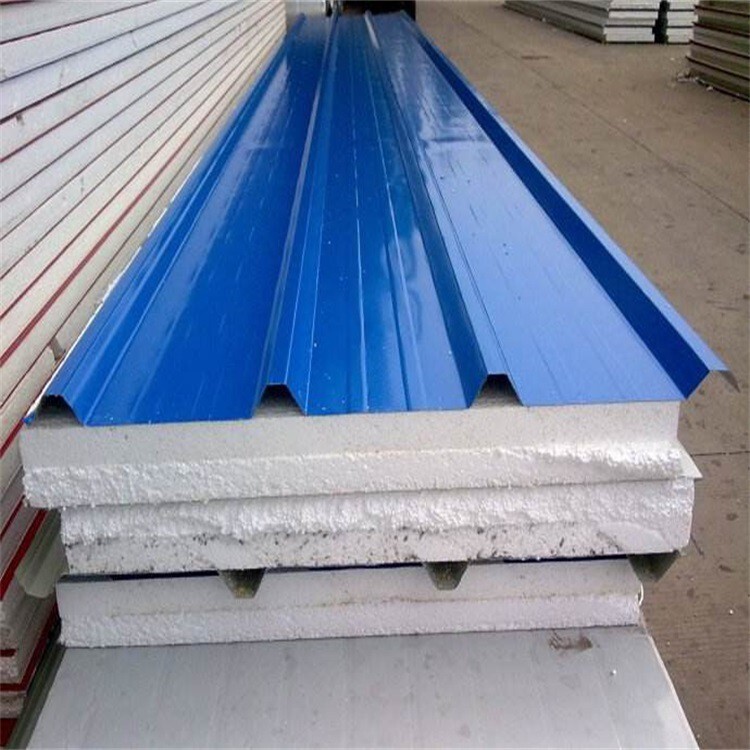

The composite board with polyurethane as the core material is composed of upper and lower color steel plates and foam polyurethane in the middle. It adopts the six component online automatic operation mixing pouring technology in the world, which can complete the mixing process of the social batching center or factory at one time online, and can be adjusted online at will according to the temperature, so as to produce distinctive high-strength, energy-saving, green and environmental protection building boards.

Because of its good fireproof and moisture-proof performance, it is also commonly used as the edge sealing core material of other material composite boards. The polyurethane edge sealing composite board is made of color coated steel plate as the surface material, continuous rock wool and glass wool as the core material, and highly rigid foamed polyurethane as the tongue and groove filling. After high-pressure foaming and curing, it is automatically dense cotton cloth and formed and compounded by the control of super long double covering tape, Compared with traditional cotton hanging maintenance materials, it has better fireproof and thermal insulation effects, longer performance, convenient installation and elegant appearance. It is a steel building maintenance material.

It is generally used for the roof outer panel of buildings. The panel has good thermal insulation, heat insulation and sound insulation effects, and polyurethane does not support combustion, which meets the requirements of fire protection. The combination of upper and lower boards and polyurethane has high strength and rigidity. The lower board is smooth and smooth with clear lines, which increases the indoor beauty and flatness. It is a new type of building material with convenient installation, short construction period and beautiful appearance.

The sandwich panel has light weight, beautiful appearance and good anti-corrosion performance, and can also be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and has played a good role in replacing wood with steel, construction, energy conservation, pollution prevention and other good effects.

Color steel plates have long been used for migration because of their lightness and ease of installation and disassembly. Later, with different requirements for materials for different purposes, color steel plates for prefabricated houses have gradually been endowed with many functions, such as fire and heat insulation for storage of materials, thermal insulation materials for breeding, simple structures for temporary residence, and earthquake and wind resistance for the environment. What other functions besides the above

The waterproof coating for color steel plate of movable plank house is a solvent type, emulsion type or powder type coating made of synthetic high molecular polymer, high molecular polymer and asphalt, high molecular polymer and cement as the main film-forming materials, adding various additives, modified materials, filling materials, etc. The coating is applied to the roof, basement, toilet, bathroom and exterior wall of the color steel plate of buildings and movable plank houses and other base surfaces that need waterproof treatment. It can form a continuous, integral and certain thickness waterproof coating layer of movable plank houses under normal temperature.

How to repair roof leakage?

The slope of color steel plate roof is generally small, often below 6%. This kind of structure is common in areas with more rain in central and southern China. There are large areas of water leakage, and water leakage at the junction of daylight windows and roof ridges. It is necessary to understand and analyze its structure, leakage points and causes when treating the leakage of color steel plate roof.

Generally speaking, the leakage of color steel plate roof is mainly caused by such factors as self tapping screws, color steel plate lapping, ridge tiles, blind rivets, deformation of color steel plate caused by people on the roof, and the falling off of waterproof glue at decorative parts such as lighting windows. The corresponding leakage points can be divided into the following:

1. Water leakage at roof screws and fasteners

This phenomenon mainly occurs in the double-layer color steel plate and single-layer color steel plate roof. During the construction process, the tapping force is too heavy and light, and the self tapping rubber gasket may be deformed, shed, or form a concave surface, which may cause the roof to drip water and accumulate through the insulation cotton. In addition, one of the important reasons for water leakage is that the position of self tapping wire is not correct, and the hole is directly formed due to missing the purlin under the color steel plate. This leakage phenomenon may not be obvious in the roof structure of single-layer color steel plate without thermal insulation system, mainly because the rainwater is directly dispersed through the contact part of steel plate and purlin, and may not drip rapidly.

2. Water leakage at overlapping of color steel plate

Horizontal lap joints, vertical lap joints, and color steel plate lap joints are leaking. If the color steel plate tile wave is too low or the rainfall is too large to exceed the tile wave, it is easy to form a large area of water leakage, and it is not easy to find the leakage point. Once it is difficult to repair, this situation is more common in curved roofs. The main reasons are that the lapping between the two plates is not tight, and the self tapping wire is not fully filled to form a gap, etc.

3. Ridge tile leaks

In the construction of light steel structure roof, water leakage caused by roof ridge tile is also a common phenomenon. In the rainy season, especially when the amount of rainwater is large, the rainwater splashes through the gap between the two color steel plates at the lower part of the ridge tile, forming a large area of leakage.

After understanding the structure of color steel plate roof, possible leakage points and reasons for leakage, let's talk about the treatment plan again. Based on years of construction experience, two leakage schemes are proposed:

1. Re waterproof the roof as a whole

This scheme can make the color steel plate roof form a waterproof layer connected integrally, and self-adhesive coiled material is recommended for urban engineering waterproof. The self-adhesive coiled material is a waterproof and sealing material that can bond with the base surface itself. It can be divided into tire self-adhesive and tire free self-adhesive. The tire is self-adhesive, and the upper and lower parts are made of the adhesive intermediate clamping base. The upper covering is vinyl film, and the lower covering is peelable silicone oil film. Tire free self-adhesive is composed of self-adhesive adhesive, upper vinyl film and lower silicone oil film. The product has self-healing property, that is, when the coiled material is punctured or embedded with hard objects, it will automatically integrate with these objects, and still maintain good waterproof performance. See: self-adhesive rubber asphalt waterproof coiled material for detailed product characteristics

2. Waterproof treatment shall be carried out for roof screws and fasteners, color steel plate lap joints and ridge tiles. The construction process is as follows: clean the base course, paint the base course, treat the waterproof material, and paint the waterproof coating for the construction of the additional reinforcement layer.

The above two schemes can effectively control the leakage of color steel plate roof, and the specific selection can be judged according to the construction area and other factors.

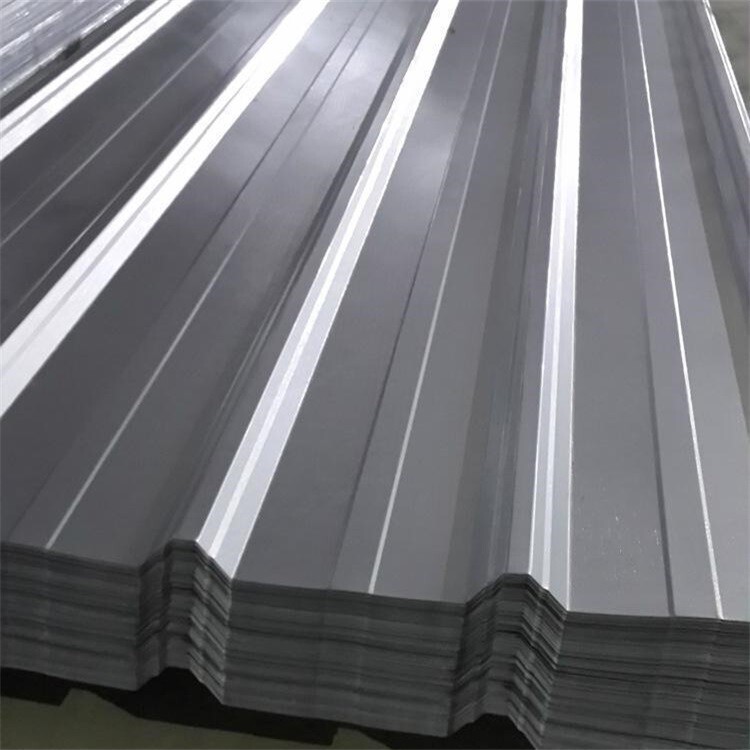

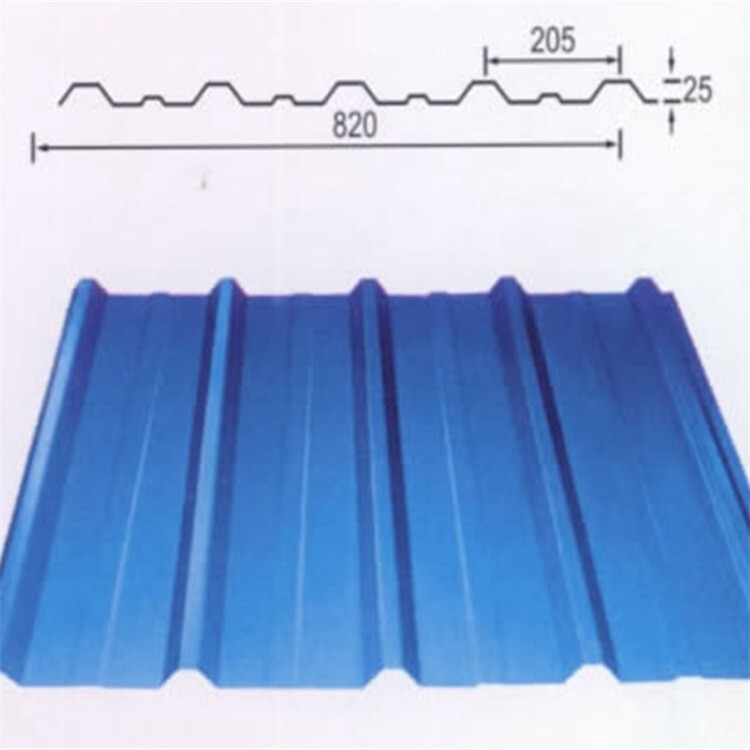

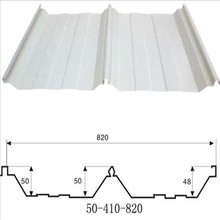

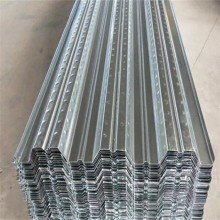

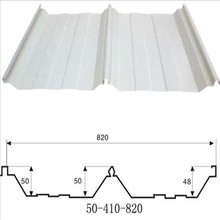

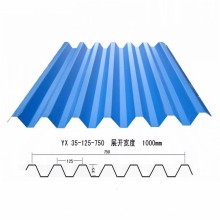

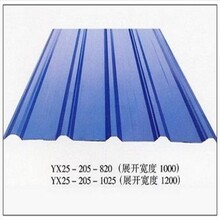

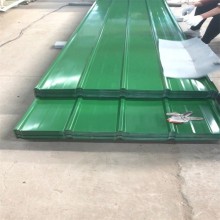

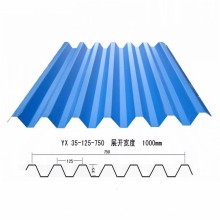

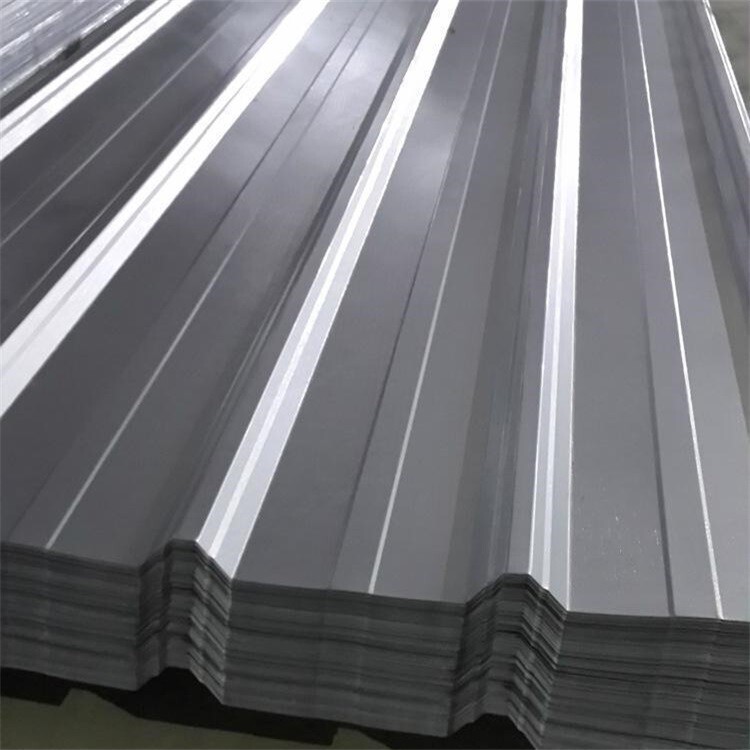

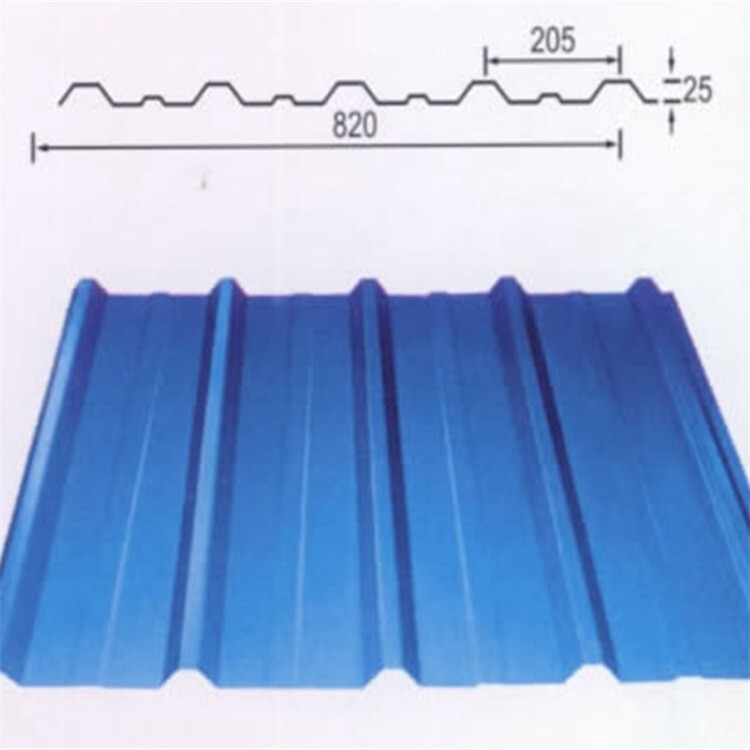

Color steel plate refers to color coated steel plate, which is a kind of steel plate with organic coating. Color steel plate is divided into veneer, color steel composite plate, floor bearing plate, etc. It is widely used in the walls and roofs of large public buildings, public workshops, prefabricated houses, and integrated houses.

Basic characteristics of color steel plate

1. Light weight: 10-14 kg/m2, equivalent to 1/30 of the brick wall.

2. Thermal insulation: thermal conductivity of core material: λ<=0.041w/mk.

3. High strength: it can be used as the bearing plate of ceiling enclosure structure, bending resistance and compression resistance; Generally, beams and columns are not used in houses.

4. Bright color: no surface decoration is required, and the retention period of anti-corrosion coating of colored galvanized steel plate is 10-15 years.

5. Flexible and fast installation: the construction period can be shortened by more than 40%.

6. Oxygen index: (OI) 32.0 (provincial fire product quality inspection station).

The color steel plate activity room has the advantages of light weight, high strength, thermal insulation, beauty and so on. It is a fast building installation integrating architecture and decoration. The construction of color steel plate movable houses is clean, and they are widely used in large-span factories, warehouses, office buildings, villas, rooftop floors, air purification rooms, refrigerators, stores, kiosks and temporary houses. The light color steel sandwich panel with a weight of less than 14KG per square meter can fully reduce the structural load and reduce the structural cost of the mobile house.

The color steel plate for building generally uses hot-dip galvanized steel plate and hot-dip aluminized zinc steel plate as the base plate, which is mainly processed into corrugated plate or polyurethane composite sandwich plate, and is used to build roofs, walls, and doors of industrial and commercial buildings such as steel structure plants, airports, warehouses, freezers, etc.

Color board for household appliances is generally based on electrogalvanizing and cold plate, which is used to produce refrigerators and large air-conditioning systems, freezers, toasters, furniture, etc.

In the transportation industry, electrogalvanizing and cold plate are generally used as the base plate, which are mainly used for oil pan, automobile interior trim, etc.

Installation method of color steel plate:

1. Setting out: setting out shall be carried out according to the drawing and the measured size on site (the center line of the partition wall), and the center line of the ground rail shall be snapped at the intersection of the two edge closing center lines and the ground. These four lines should be in a vertical plane, so that the wall installed later is vertical;

2. Roof rail: it shall be installed neatly, and the interface shall be reinforced and repaired. It shall be fixed on the cement ceiling with nails or screws every 500mm-600mm;

3. Ground rail: when installing the ground rail, reserve the installation position of the door first, and pay attention to the ground difference. If the height difference of the ground is too large, it must be leveled to reduce the drop, which will not affect the adjustment of the level. The floor shall be fixed by hitting or screwing every 600mm. If the ground joint is too large, it shall be filled with caulking agent;

4. Edge trimming: cut the edge trimming according to the actual measured value, and trim the edge after cutting. Try to be neat and consistent, and the joints are required to be seamless. Pay special attention to the interface with the ceiling and skirting board, and make sure there is no gap;

5. Vertical keel: a vertical keel (half of the size of the partition) shall be placed every 49cm, and the columns on both sides of the door frame shall be completely fixed up and down without shaking. A vertical keel shall be added in the opposite direction, and the width of the door leaf shall exceed 90cm. The horizontal column on the door frame shall be strengthened and fixed, and welding shall be used if necessary;

6. Horizontal through keel: if the height is more than 3 meters, one keel shall be placed 1.2 meters in the vertical direction. When two keels are connected, the overlapping length shall not be less than 10 cm;

7. Wall panel: color steel plate shall be installed from one side in turn, and the spacing between connected panels shall be 12mm. 12mm wide battens are used between diaphragms, and standard unit wallboards can be interchanged.

What is color steel plate:

In short, it is a kind of decorative steel plate with bright colors, and it is also a common building material. This material is very novel and beautiful for other plates in terms of color and style, and it is easy to install, so it is liked by everyone. It is often found in warehouses and temporary buildings. With the development and progress of society, there are more and more materials in the decoration market, of which the color steel plate is a common one, accounting for a very large proportion in the application, which has guaranteed our safety. The overall installation is also very simple, so it is liked by everyone.