1、 Material Introduction

Epoxy modified siloxane anticorrosive and waterproof coating is an ideal environmental protection anticorrosive and waterproof coating made of epoxy resin composite as the main binder, inorganic filler and various additives. This product has good corrosion resistance and meets the requirements of GB/T50046-2018 Code for Anticorrosion Design of Industrial Buildings and GB/T17219-1998 Standard for Safety Evaluation of Drinking Water Transmission and Distribution Equipment and Protective Materials. The modified siloxane anticorrosive and waterproof coating is a green anticorrosive coating, which is environmentally friendly. It can be applied on the wet and dry surfaces of concrete. The coating after construction is elastic, easy to apply, fast to dry, and strong in adhesion. The successful research of modified siloxane anti-corrosion and waterproof coatings has added a very good reputation to the water-based anti-corrosion coatings in China. It has made great contributions to the corrosion prevention of concrete structures in China, reducing pollution, improving the effectiveness of corrosion prevention, and creating a green environment.

2、 Product features

The epoxy modified siloxane anti-corrosion and waterproof coating is mainly applicable to the anti-corrosion and waterproof of industrial and domestic sewage treatment plants, waterworks, sewage pools, roof of buildings, toilets, garbage landfills and water pipelines. This product has the following advantages:

1. Convenient construction: no other materials are required for construction, and can be brushed, sprayed or roller coated.

2. It can penetrate into the base and stick firmly to the base, with good waterproof, anti-corrosion and impermeability.

3. The film is fast and can be constructed on dry or wet base course.

4. This product is tasteless, flame retardant, and can be used for waterproof of various edible pools or drinking water projects, and can be equipped with various color coatings as required.

Scope and conditions

The epoxy modified siloxane anti-corrosion and waterproof coating is mainly applicable to the protection and impermeability of concrete structures in industrial sewage and domestic sewage treatment plants, as well as the anti-corrosion of food industry, bioengineering, pharmacy, tap water plants and other environments with high environmental requirements, and the protection of water transmission pipelines. It is also applicable to the anti-corrosion of the inner wall of the drying tower in power plants, and the anti-corrosion of concrete structures in garbage landfill.

5、 Construction operation specification

The epoxy modified siloxane anti-corrosion and waterproof coating is characterized by no special requirements on the shape, position and type of the base course. It has strong applicability and is suitable for various base course materials. Its construction operation can be summarized into the following three links.

(1) Base course preparation

1. The base course shall be flat, compacted and polished, without sharp edges, honeycombs, pits, bulges and cracks, or it shall be treated to meet the above requirements.

2. The construction waste and floating ash on the surface must be cleaned up.

3. There should be no water on the base course, otherwise it should be drained and cleaned.

(2) Material preparation

1. Mix proportion: the epoxy modified siloxane anti-corrosion and waterproof coating shall be accurately measured according to the mix proportion provided by the manufacturer and mixed evenly.

2. Mixing requirements: during mixing, slowly pour solids into the liquid and fully mix with the agitator for not less than 10 minutes until there is no bubble. During mixing, do not add or mix the residual liquid and other impurities from the previous mixing.

3. Cleaning: after each batching, clean the batching bucket, mixing blade and other appliances and equipment with clean water, otherwise the quality of the next batching will be affected.

(3) Coating construction

The modified siloxane anti-corrosion and waterproof coating can be mechanically sprayed or manually brushed.

1. Mechanical spraying

The airless spraying machine can be used for construction, and the spraying times shall not be less than two.

2. Manual brushing

Use a long plate brush or a round rolling brush of more than 150mm for painting. The painting shall be carried out horizontally and vertically in a crisscross manner to achieve a flat and uniform thickness.

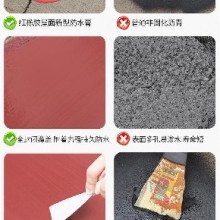

Features of modified siloxane anti-corrosion and waterproof coatings:

1. It is resistant to high strong acid, strong alkali, salt, industrial sewage, domestic sewage, seawater, solvents, etc.

2. Aging resistance.

3. Good resistance to microbial mold.

4. It is harmless and can be used for drinking water engineering.

5. High bonding strength.

6. Strong ozone corrosion resistance.

7. After the film is formed, the elongation rate is large, the elasticity is rich, and the concrete surface has good adhesion.

The modified siloxane anti-corrosion and waterproof coating is mainly applicable to the protection, anti-corrosion and waterproof of industrial and civil buildings; For example, the concrete structure protection of industrial and domestic sewage treatment plants is also applicable to the anti-corrosion of biological engineering, waterworks and other environments, and the protection of water transmission pipelines. It is also applicable to the anti-corrosion of the inner wall of the water tower in the power plant, and the anti-corrosion of the concrete structure of the garbage landfill,

Introduction to epoxy modified siloxane anti-corrosion and waterproof coatings:

1. The film forming material of siloxane anti-corrosion and waterproof coating is a mixed liquid system of waterborne polyester, fluorocarbon resin, polyethylene, polytrifluorochloroethylene, tertiary carbonate, polysiloxane and other resins.

2. Polyethylene has good stability, extensibility, water resistance and weather resistance due to its main chain bond; Polytrifluoroethylene has good acid resistance, alkali resistance, salt resistance and mold resistance; Tertiary carbonic acid is used to react with inorganic curing agent and graft to resin, especially to play a strong bonding role with concrete surface; Polysiloxane has strong defoaming and wetting effects, which is conducive to the full compatibility of powder and liquid materials, and has good permeability.

Product Introduction

The epoxy modified siloxane anti-corrosion waterproof coating takes cement as the base material, mixed with special acrylic acid series and additives, has active chemicals, and has very good adhesion and impermeability. It is a rigid permeable waterproof material that penetrates into the pores of the building wall through the carrier, expands when dry, and forms a tough impermeable waterproof barrier layer, It is an ideal waterproof coating under rather harsh use conditions. No matter indoor or outdoor, brick walls on the ground or underground, brick slag block walls, concrete walls in the basement, water retaining walls, green retaining walls, concrete walls, clean water pools, swimming pools, sewage treatment pools, underground garages, etc. can achieve a fairly good waterproof and anti-corrosion effect.

The epoxy modified siloxane anti-corrosion and waterproof coating is applicable to: the anti-corrosion of the inner wall of the pool of the industrial circulating water system, the storage tank of the water treatment system, the concrete and metal pool walls and pipes, the grouting of the cement bottom buildings, the railway and other foundations, ports, docks, piers, coal mines, oil fields, geological drilling

Epoxy modified siloxane anti-corrosion and waterproof coating is applicable to various industrial and civil buildings, roofs, internal and external walls, toilets, kitchens, gutters, balconies, warehouses, water tanks, sluices, and other waterproof, moisture-proof, anti-corrosion and other projects.

Ambergar brand: epoxy modified siloxane anti-corrosion and waterproof coating, water pool waterproof and anti-corrosion, fire pool waterproof and anti-corrosion coating.

Epoxy modified siloxane anticorrosive and waterproof coatings are commonly used in: domestic water pool, drinking water pool, clean water pool, fire water pool, sewage pool, cooling tower, water tower, cooling tower, bridge deck, etc. Edith brand: epoxy modified siloxane anti-corrosion waterproof coating is used for steel structure and concrete with strong adhesion, waterproof, moisture-proof, leak proof, mildew proof, anti-corrosion, performance, safe and simple construction, short construction period and other advantages.

Product features

Permeable to concrete base surface; At the same time, it can hydrate with cement base material; High bonding strength and toughness; Compressive strength; Fast curing speed; Water resistance; The strong hydrophobic additive is introduced in the formula, and the coating interface has "lotus leaf effect" when encountering water. The construction process is simple and the labor intensity is low.