Shenzhen Zhuohuixin Technology Co., Ltd

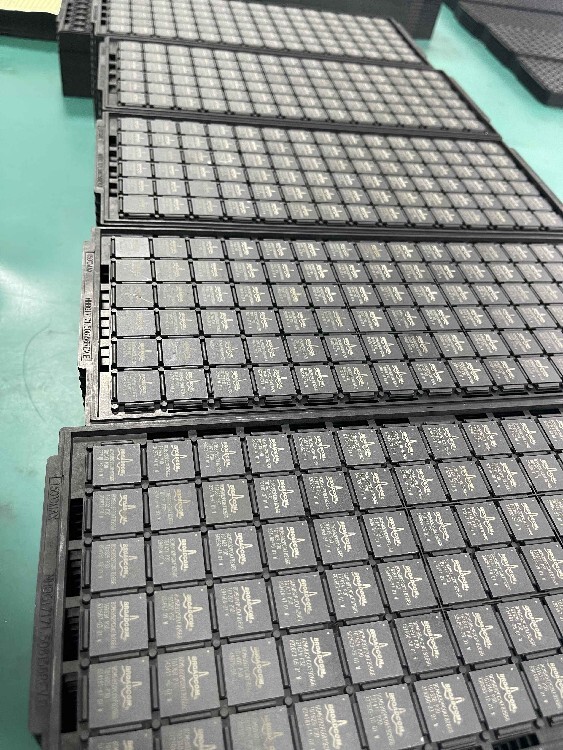

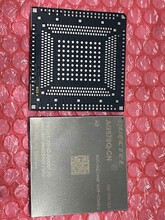

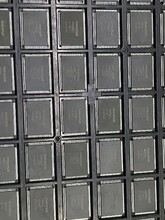

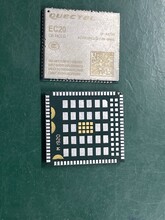

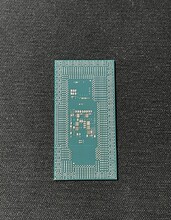

It is an enterprise engaged in the processing of electronic components. Its main businesses include: BGA ball planting, QFN tin removal, QFP tin removal, IC grinding and lettering, IC laser burning, IC cover lettering, IC tape weaving and vacuumizing, IC board removal and renovation, etc. Protect intellectual property rights and prevent technology leakage. IC: BGA/OFN/DIP/DDR/EMMC/EMCP/SSD/SOP/SSOP/SOT/TO/PLCC series and various irregular packages can be processed.

The whole process is environmentally friendly, anti-static, and customer information is highly confidential. With high-quality talents, years of chip processing experience and rate, and high precision processing equipment, the company is dedicated to providing services to our customers!

The company's business purpose: quality, customer first! Welcome new and old customers to visit our company!

Our service: BGA CPU QFN QFP SOP TSOP CCM glass chip

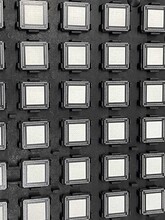

Drying dehumidification, disassembly, tin removal, oxidation removal, ball planting, cleaning

Washing, trimming, presser foot, polishing, covering, typing, taping, etc

art

BGA repair welding and material replacement after SMT chip furnace