Project Background

China's economy is in the process of transformation from high-speed growth to high-quality development. With the industrial upgrading, China's manufacturing industry will gradually shift from "Made in China" to "Made in China". This requires manufacturing enterprises to develop towards "green" and "efficient". In this context, as one of the traditional high energy consuming industries, the textile printing and dyeing industry is facing severe challenges of high cost, environmental protection and emission reduction. However, Meixinda, a textile printing and dyeing enterprise, has already taken the lead and had a response.

As early as 2005, Meixinda began to transform to green and environmental protection. With the development of 5G, AI, IoT and other technologies, Meixinda's green development path has entered a more "smart" stage. With the help of Baidu Intelligent Cloud's AIoT intelligent solution, Meixinda has successfully built an AIoT intelligent energy management service platform. Through APS intelligent production scheduling, energy management application, intelligent cloth inspection system and color difference management system, on the basis of effective energy management and control, cost reduction and efficiency increase, product competitive advantage is more obvious, and enterprise comprehensive strength is greatly strengthened, setting a benchmark for the transformation and upgrading of traditional manufacturing industry.

Customer pain points

Although Meixinda has a relatively complete energy efficiency management system, it effectively controls and analyzes the energy of the whole plant. However, due to the measurement coverage, timeliness and multi-dimensional data analysis of business data, enterprises can no longer support further cost control from the energy dimension. Especially outstanding in quality improvement, personnel management, energy consumption and environmental protection, and product delivery.

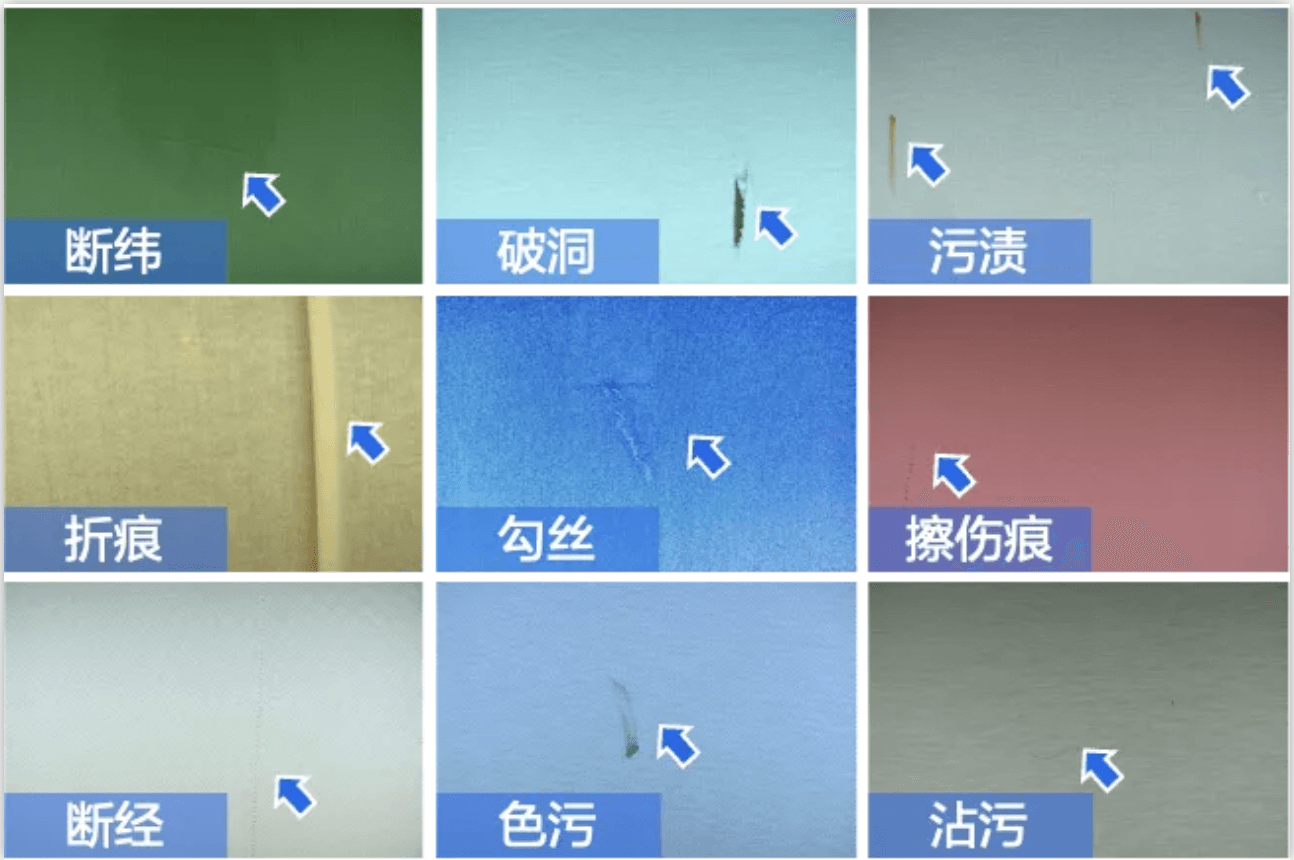

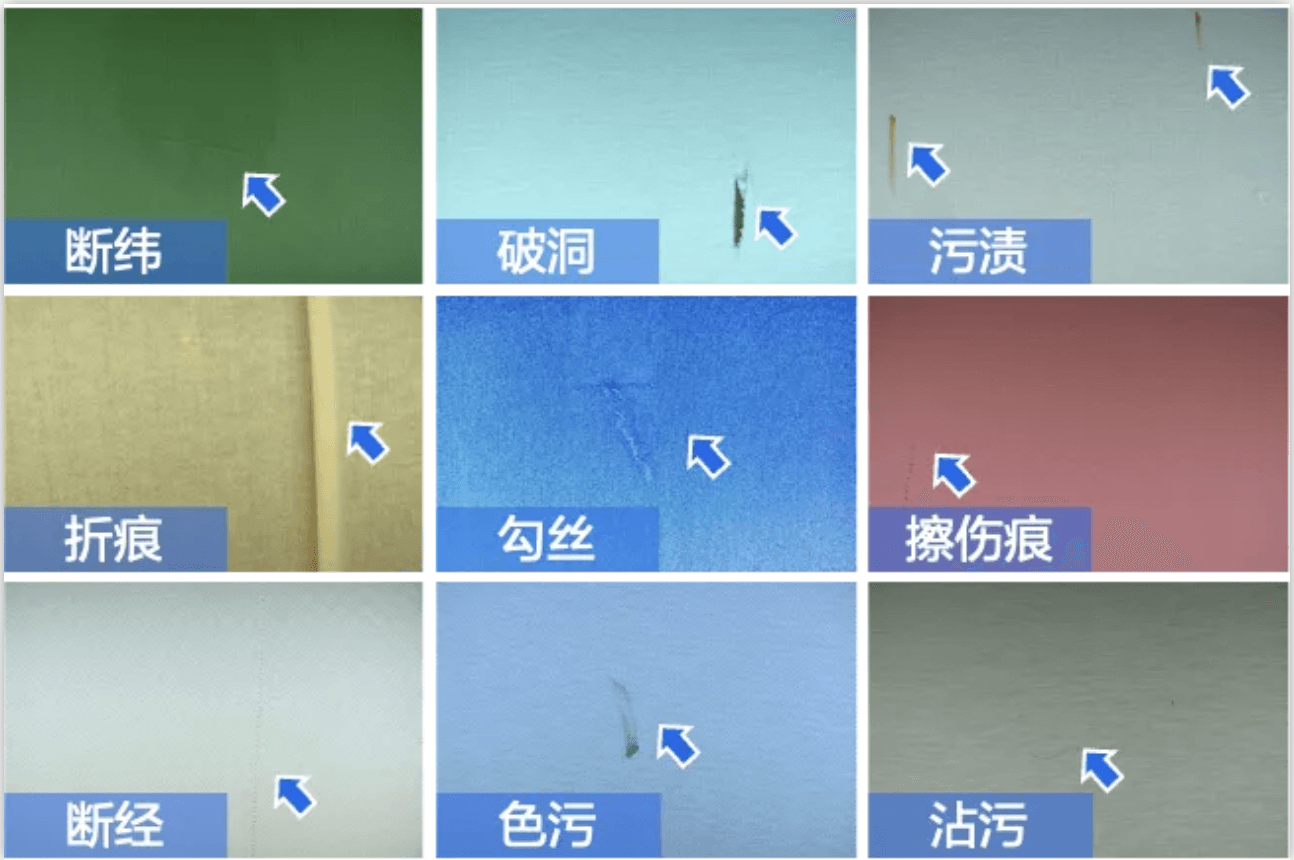

First of all, the product testing is heavily dependent on the subjective judgment of the human. Affected by emotions, emergencies and other factors, the consistency of testing quality cannot be guaranteed manually. Moreover, the ability of manual detection is limited, so it is difficult to improve the detection efficiency.

Secondly, the problem of personnel management is becoming increasingly serious. On the one hand, it is difficult for manufacturing industry to recruit, train and retain workers; On the other hand, the labor cost has accounted for 20% - 30% of the product cost, and the wage rise and social security have brought much pressure. "The post-90s and post-00s are not willing to do traditional industries, and many of the teachers' experiences cannot be inherited with the increase of age, which leads to many problems in the enterprise foundation. How can we turn the original manual inheritance into the whole process of data?" Long Fangsheng, general manager of Meixinda, has been thinking about this problem.

Thirdly, in the aspect of energy consumption and environmental protection, there is a contradiction between "one big and one small": in the production process, the consumption of electricity, water and steam is large, while the coverage of advanced applicable technologies that play an important role in improving enterprise production efficiency and energy conservation and consumption reduction is very small, and the automation equipment technology is immature. The contradiction between the two makes the energy consumption problem more prominent.

At the same time, facing the market demand, personalized products are gradually increasing. The requirements of multi variety, small batch and fast delivery not only increase the difficulty of product delivery, but also lengthen the idle time of production line change and increase the difficulty of production scheduling.

Therefore, opening up the information island, relying on the actual business of the enterprise, establishing a perfect energy management service platform, and promoting the further development of enterprise energy efficiency management and cost management and control are the most urgent problems that need to be solved by Maxinda.

Solution

The engineers of Baidu Smart Cloud have a deep understanding of the practical problems of Meixinda's business, created a smart energy model tailored for Meixinda, realized comprehensive production and energy efficiency management at the equipment layer, resource layer, platform layer, and application layer, and created more possibilities for production guidance and management with intelligence, digitalization, Internet of Things, and visualization.

APS intelligent production scheduling

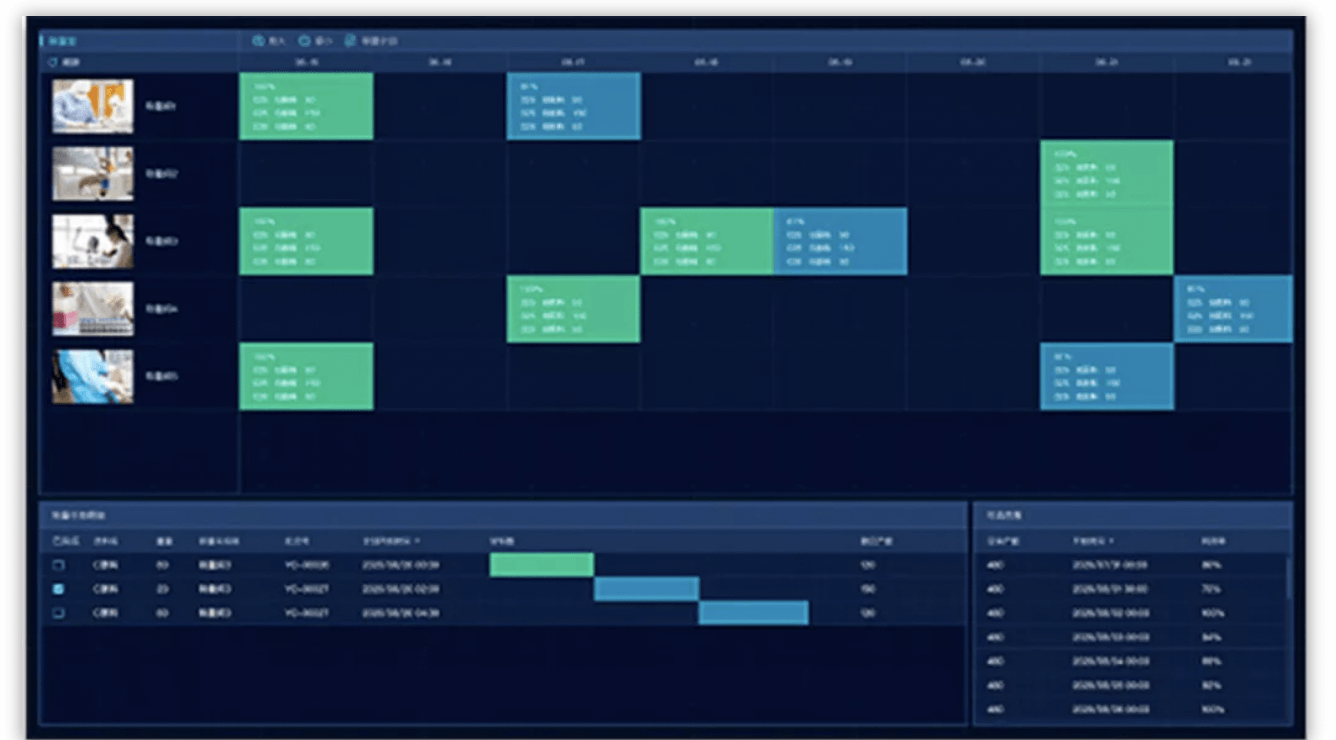

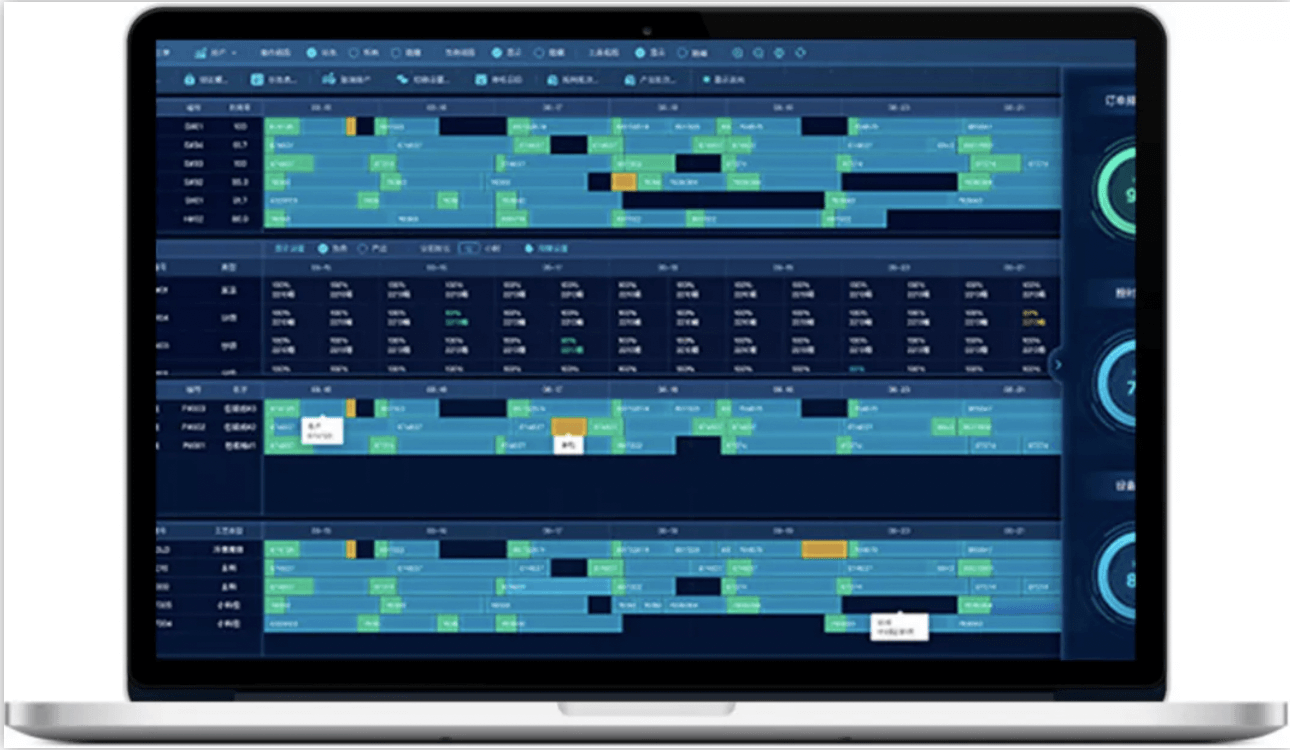

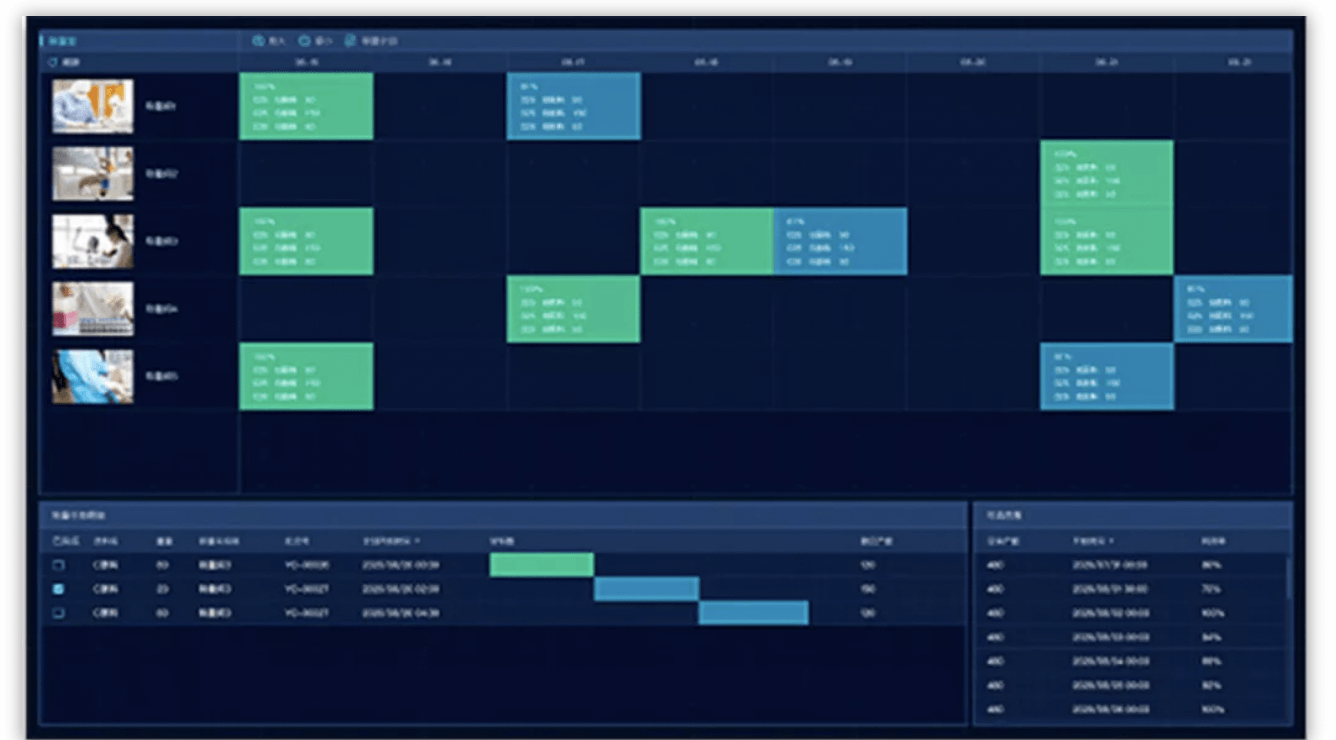

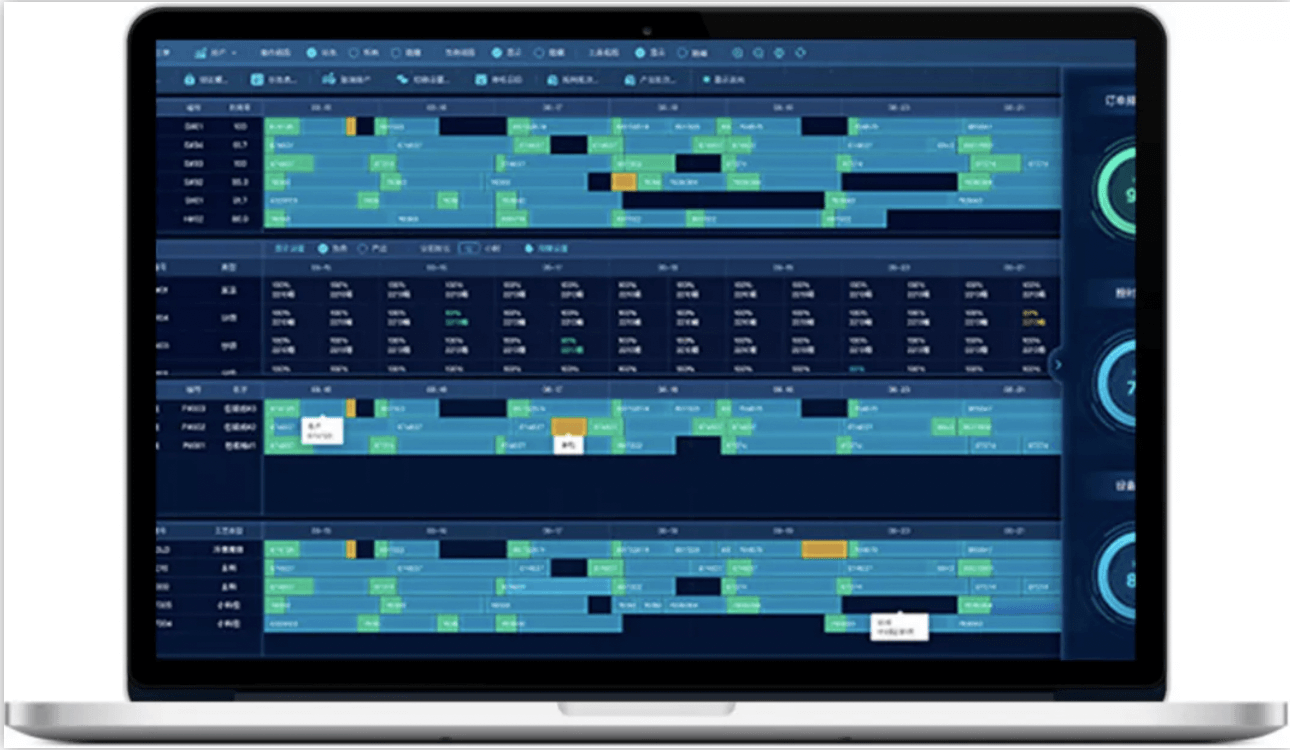

In terms of intelligent scheduling, AI based intelligent scheduling has realized the optimal solution of production plan. With the help of Baidu Smart Cloud's mature APS intelligent scheduling service, Meixinda has established a standardized management of processes and business rules, and with the help of visual intelligent scheduling, it has achieved all-round control of production plans and production conditions, thus adjusting production scientifically and reasonably, and constantly improving order delivery rate.

At the same time, through the system's rapid and flexible use of different strategies for planning and scheduling, Meixinda continuously optimizes the overall production efficiency, creating greater profit space.

- Visual intelligent production scheduling

Energy management application

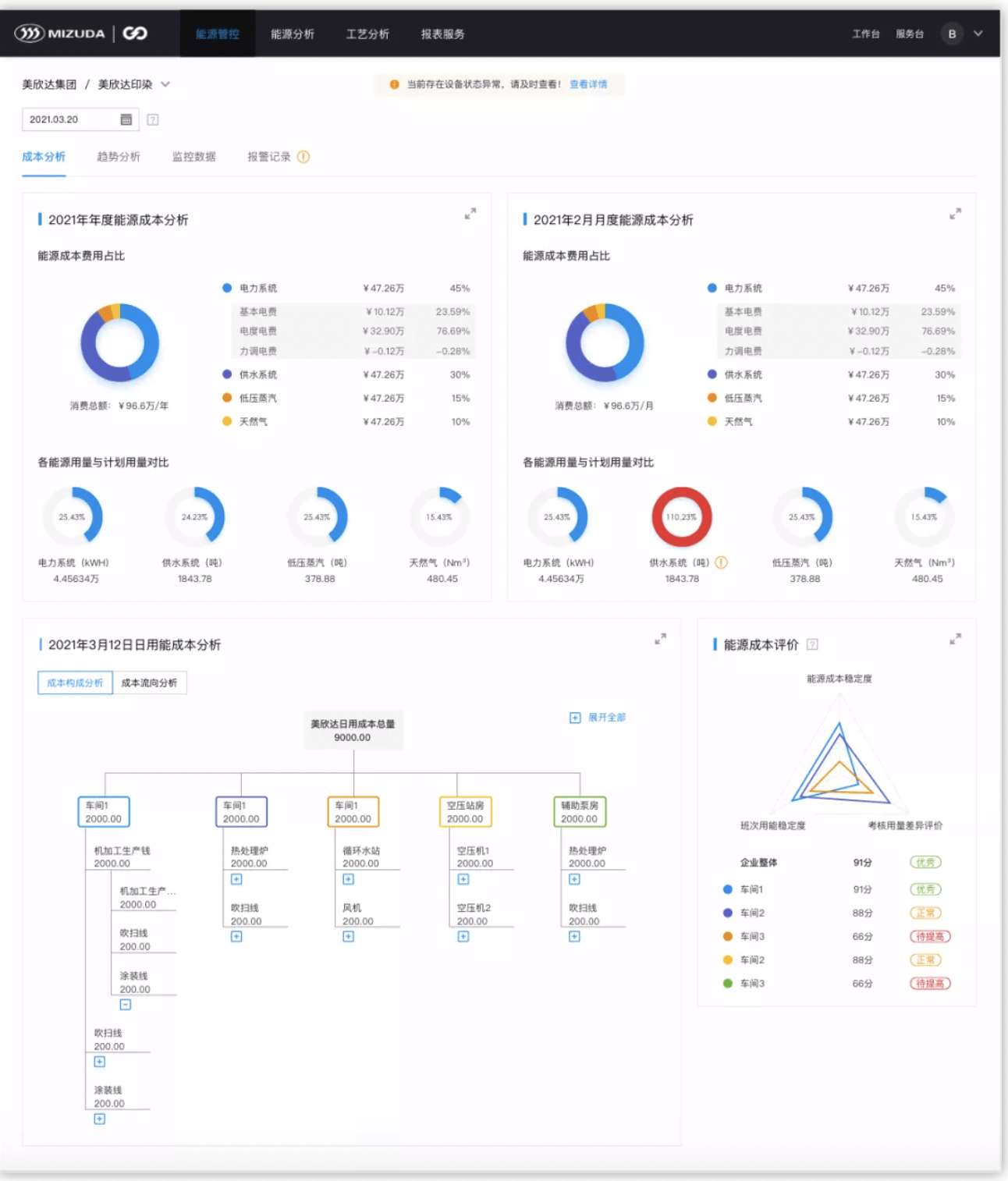

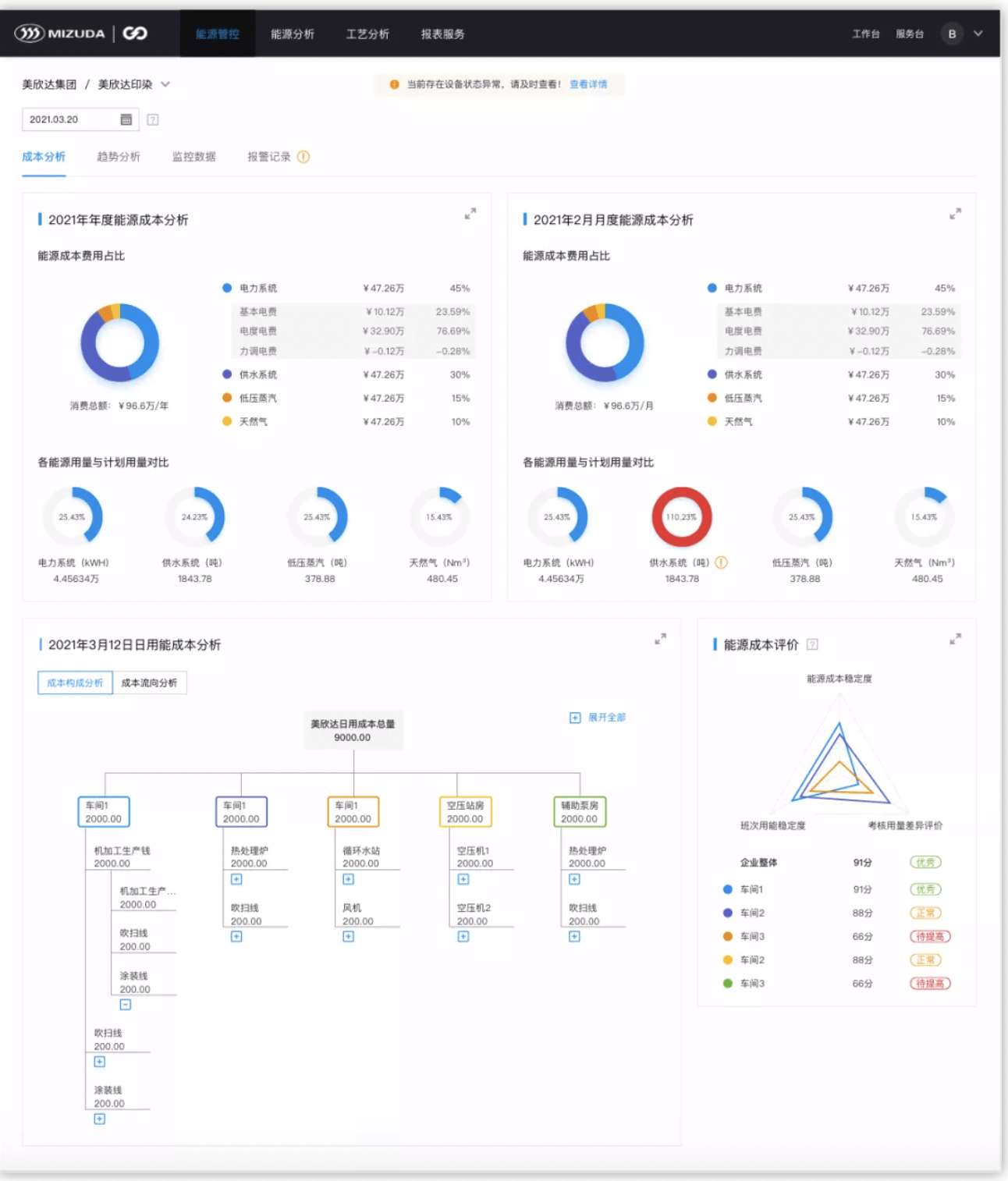

In terms of energy management, through Baidu Intelligent Cloud Energy, the on-site energy data, quality data analysis and energy consumption data are digitally displayed. And through energy consumption evaluation, energy consumption data monitoring, energy consumption report, energy consumption analysis, etc., combined with energy data, the enterprise standard energy system, equipment system, instrument management, accounting analysis model was established to achieve the consistency of basic data.

Through the system level analysis of energy data and the in-depth application of energy data, Meixinda has continuously improved the stability of the energy system, improved energy efficiency, and realized the feedback of data to the production process.

- Energy cost analysis interface (example)

Intelligent cloth inspection system, color difference management system

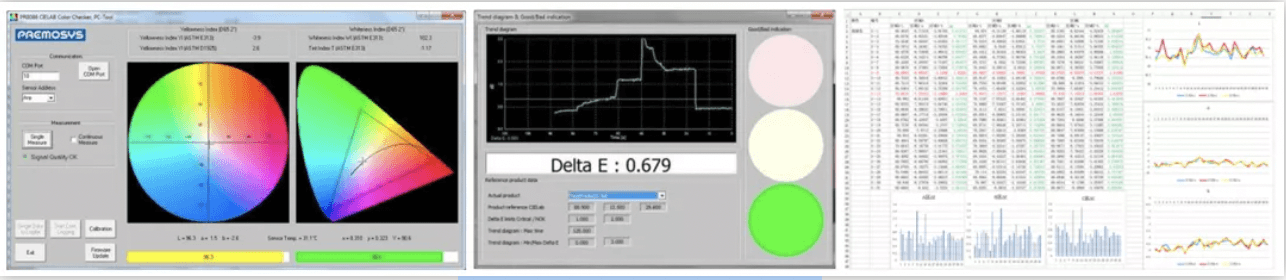

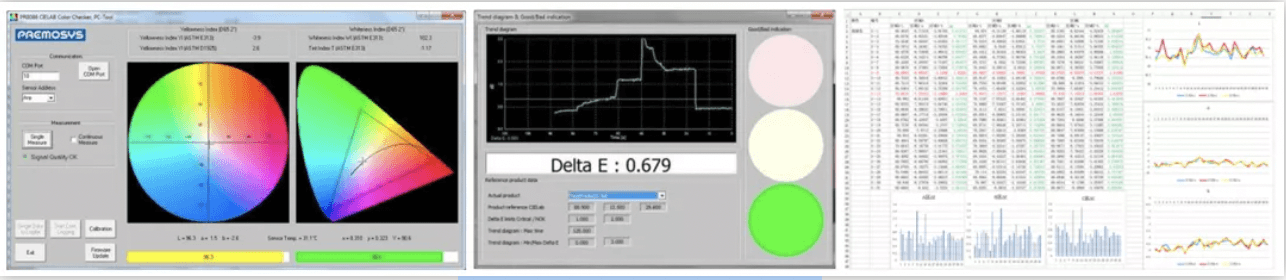

With the support of Baidu Intelligent Cloud Tiangong Internet of Things platform, Meixinda has realized the automation of color difference inspection. The system generates inspection data by detecting fabric defects on the line, and integrates with the platform to complete the output of fabric inspection reports in real time and standardization, which can clearly show the key characteristics of fabrics and provide local printing and online reference.

In addition, the color difference management system can quickly identify the color difference of the batch head sample, generate the color difference detection report of the batch head sample, improve the one-time pass rate, reduce color correction, and eliminate re dyeing and color change.

- Automatic AI recognition of fabric defects

Fixed point detection, continuous detection, report export

Customer income

APS intelligent production scheduling

Meixinda has established standardized management of processes and business rules with the help of Baidu Intelligent Cloud's mature APS intelligent scheduling service.

Energy management application

Through the system level analysis of energy data and the in-depth application of energy data, Meixinda has continuously improved the stability of the energy system, improved energy efficiency, and realized the feedback of data to the production process.

Intelligent cloth inspection system, color difference management system

With the support of Baidu Intelligent Cloud Tiangong Internet of Things platform, Meixinda has realized the automation of color difference inspection.