Shanghai Baoshan Recycling Carbon Black Factory

Source: Chaoran Trading Firm, Lanshan District, Linyi City

Time: 2024-06-26 07:04:09

[Report]

High temperature surface treatment refers to high-temperature heat treatment of precipitated white carbon black to remove some molecules adsorbed on the surface of white carbon black, namely water and other low molecular weight adsorbates. As a result, partial vulcanization characteristics can be improved, but the effect is not significant. Surface chemical treatment is to use some chemical reagents to react with the surface active silanol group of silica, so as to improve the affinity and reaction activity of silica with polymer rubber. There are many reagents that can chemically treat the surface of white carbon black, and there are various chemical treatment methods. There are many literatures and patents in this regard. The following is a brief introduction. The specific process methods are as follows: (1) steam method: directly contact the dried white carbon black with the steam of organic matter to generate the required reaction; (2) Reflux method: boil white carbon black and reaction liquid together for reflux to produce the desired reaction; (3) Hydrothermal reaction method: the reaction of white carbon black and reaction liquid in an autoclave by hot pressing. The specific chemical reactions used are: with the increase of hydration degree, the isolated silanol group gradually decreases, while the ortho silanol group gradually increases. Ortho silanol group has strong adsorption capacity for water and polar substances.

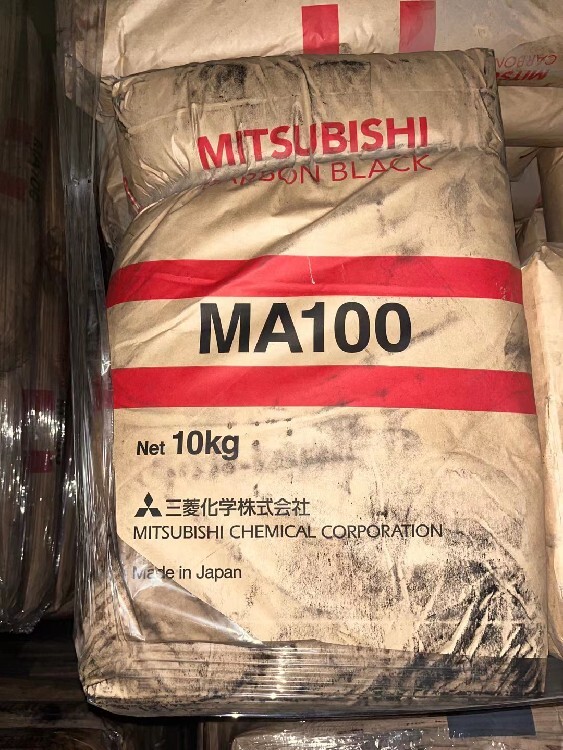

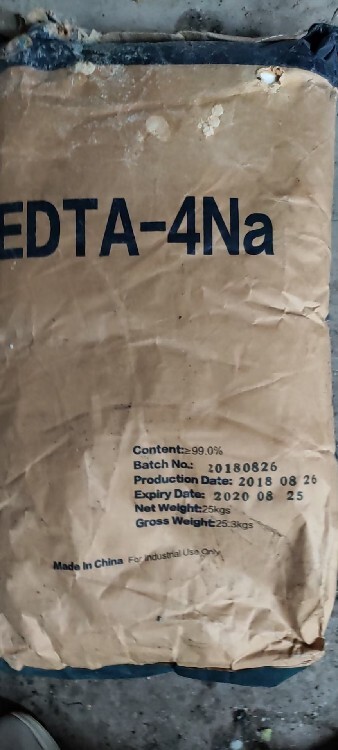

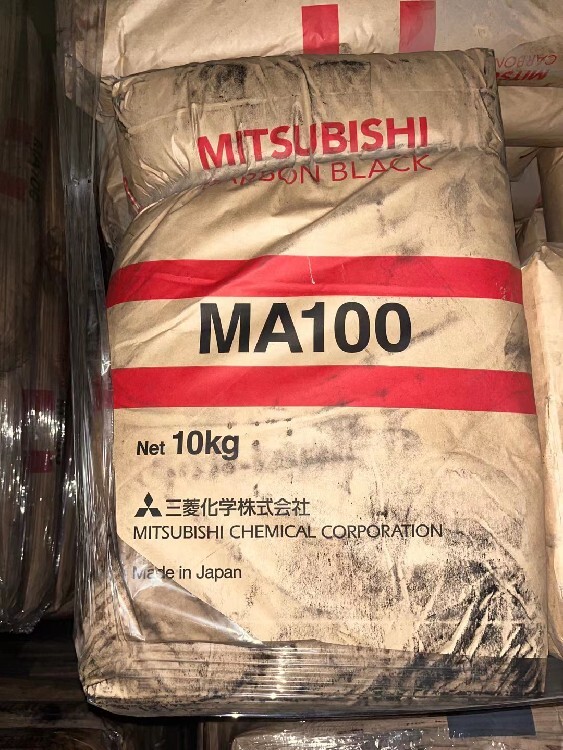

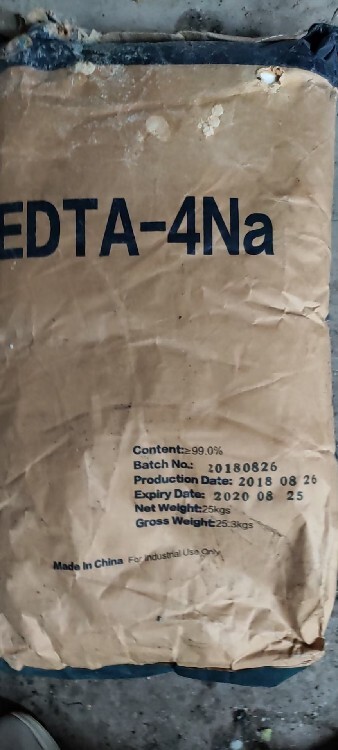

We are Guangzhou Liben Rubber Raw Material Trading Co., Ltd., which was founded in 2005. After more than ten years of efforts and steady development, we now have warehouses and transport fleets. Now it has become a powerful rubber raw materials and additives trading company in Guangzhou. The company has the agency power of more than 60 brands at home and abroad. We are more satisfied with the same products than with the same price. We are more satisfied with the same quality than with the same service. Main products: C9 petroleum resin, C5 petroleum resin, Gumalon resin, C5C9 copolymer resin, 2402 phenolic resin, terpene resin, modified resin, tackifying resin, rosin, hydrogenated petroleum resin, RX-80 resin, etc! Carbon black series: black cat brand carbon black N220 N234、N330、N326、N339、N550、660、N774、 Imported carbon black N990, natural gas semi reinforced carbon black, spray carbon black, acetylene carbon black! White carbon black: activated white carbon black, Nanji 255 white carbon black, Zhuzhou white carbon black, black cat white carbon black, public welfare white carbon black, precipitation white carbon black, ultra-fine white carbon black, vapor phase white carbon black, etc. Accelerator series: D, DM, M, CBS (CZ) TMTD、TRA、PZ、BZ、PX、TMTM、NS、DTDM、NA-22、EG-3。 Antioxidant series: RD MB、4010NA、4020、BHT、264、 A, D HS-911、SP-P、SP-C、DFC-34。 Softening oil series: dioctyl ester DOP, dibutyl ester DBP, diethylene glycol DEG, environmental plasticizer LF-30 ATBC、DOA、DOS、TOTM、 Paraffin base oil, naphthenic oil, aromatic oil, chlorinated paraffin, glycerin, snow oil, white mineral oil, pine tar! Natural rubber series: 3L standard rubber, 3 # cigarette rubber, rubber green rubber, natural latex, wind rubber synthetic rubber series: styrene butadiene rubber 1502, 1712, butyl rubber Russia 1675, Beiyan 1751, brominated butyl, chlorinated butyl; Nitrile rubber (South Korea 35L, 35LM, Lanhua N41290733043305, Japan N41, JSR220、230、240); Cis-1,4-polybutadiene rubber (Beiyan, Yuehua, Daqing BR9000); EPDM (Jihua 4045, USA 4640); Neoprene (Datong 322, Shanxi), high styrene. Filler and ingredient series: stearic acid 1801, zinc stearate, calcium carbonate, lithopone, cross-linking agent, paraffin, talcum powder, titanium dioxide, vanillin, iron oxide red (yellow), magnesium oxide, internal and external release agent, barite, white (black) ointment, kaolin, clay, loess. Our company pays attention to: genuine goods at a reasonable price, integrity principle, timely delivery, variety. The above are just common models. For more products, please call us for consultation: the company pursues the principle of "integrity oriented, reasonable win-win". Welcome to come here to exchange, inquire and order. We will serve you sincerely! Sincerely! If your factory intends to reduce costs and maintain product quality advantages, we have the ability to provide you with suitable, stable and cheap domestic raw materials for a long time. In short, we will try our best to make you satisfied and at ease!

Carbon black N550 fast press furnace black is a series of wet soft products developed and produced in recent years. The surface of N550 particles is smooth and the structure is high. It is a variety with medium reinforcement performance and good processing performance, especially it can give the rubber a high stiffness and good extrusion performance. Therefore, it is called quick extrusion furnace black. Its reinforcement performance is higher than other soft carbon black, and its wear resistance is even better than slot black, so it is also called medium abrasion furnace black (MAF). The compound has good heat resistance and thermal conductivity, especially good elasticity and resilience· N550 has been used earlier and is commonly used in tire ply, sidewall, inner tube and the compound of extruded and calendered products. It is used together with N660 in butyl rubber inner tube. This can not only meet the rubber extrusion performance, but also improve the later use performance of the product· Carbon black N660 universal furnace black is a series of wet soft products developed and produced in recent years. N660 is the main variety of N600 series carbon black. It is also called universal furnace black because it has a wide range of applications due to its high elongation stress, good processability of fast pressing furnace black, high elasticity of semi reinforced furnace black and flexibility of fine particle furnace black. Compared with semi reinforced furnace black, N660 is slightly higher in structure, finer in particles, easy to disperse in rubber, higher in tensile strength and constant elongation stress, smaller in deformation and lower in heat generation. Good elasticity, resistant to flexion, but slightly low elongation· N660 is widely used for tire ply, high-speed conveyor belt, cable, footwear and other calendered products· Packaging specification: paper plastic composite bag: 20kg/bag;

·Carbon black N550 fast press furnace black is a series of wet soft products developed and produced in recent years. The surface of N550 particles is smooth and the structure is high. It is a variety with medium reinforcement performance and good processing performance, especially it can give the rubber a high stiffness and good extrusion performance. Therefore, it is called quick extrusion furnace black. Its reinforcement performance is higher than other soft carbon black, and its wear resistance is even better than slot black, so it is also called medium abrasion furnace black (MAF). The compound has good heat resistance and thermal conductivity, especially good elasticity and resilience· N550 has been used earlier and is commonly used in tire ply, sidewall, inner tube and the compound of extruded and calendered products. It is used together with N660 in butyl rubber inner tube. This can not only meet the rubber extrusion performance, but also improve the later use performance of the product.

The traditional method of preparing white carbon black is to use sodium silicate, silicon tetrachloride and ethyl orthosilicate as silicon sources. Except sodium silicate, other costs are very high. The new method uses cheap non-metallic ore as silicon source, which greatly reduces the production cost of white carbon black. Traditional folding method (1) The vapor phase method is mainly chemical vapor deposition (CAV) method, also known as pyrolysis method, dry method or combustion method. Its raw materials are generally silicon tetrachloride, oxygen (or air) and hydrogen, which are reacted at high temperature. The reaction formula is: SiCl4+2H2+O2 ->SiO2+4HCl

The introduction is white carbon black with high reinforcement, which provides high hardness, high tensile strength, high tear strength and high wear resistance for rubber formula. In order to obtain ideal rubber properties, activators such as ethylene glycol, amine or alkaline accelerator need to be added. Because Ultrasil ® VN3 has a high specific surface area. When it is used together with other additives, it can give the transparency of vulcanized products. Scope of application Materials such as tires, rubber products, cables and soles Evonik Degussa white carbon black Ultrasil ® VN3 GR

Label: Baoshan recycled carbon black, recycled carbon black manufacturer, Shanghai recycled carbon black, recycled carbon black telephone