Recycling of obsolete and second-hand chemical products such as production transformation, transformation and elimination, factory closure, overstock and expiration of enterprises

1: Recycle polyurethane composite, recover isocyanate, recover MDI TDI titanium dioxide, titanium dioxide IPDI isoflurone diisocyanate recovery polyether polyol high resilience combination polyol combination polymer polyol diphenylmethane diisocyanate liquefaction MDI modified MDI polymerization MDI polyurethane black material isocyanate combination polyurethane AB material polyurethane foaming agent toluene diisocyanate ice box combination insulation board combination soft and hard foam combination 141B foaming agent triethylene diisocyanate Amine polyurethane chain extender Aromatic amine chain extender Diethyl toluene diamine DETDA100 80 milky white polyether

2: Recycle various dyes, raw materials and pigments

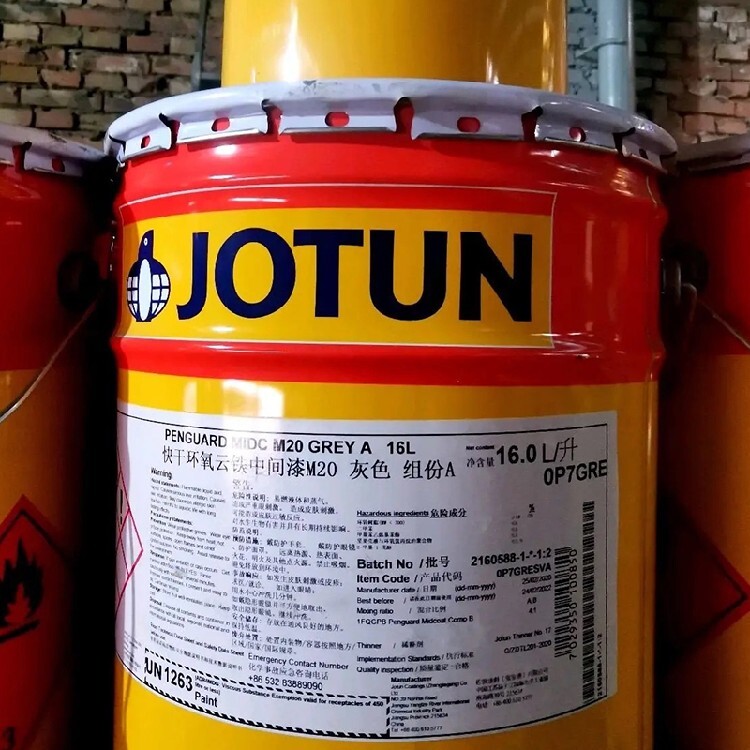

3: Recycle paint; Recycling of Wuxi self polishing antifouling paint, silicone high temperature resistant paint, interior and exterior wall paint, latex paint, wood paint, steel structure paint, automobile repair paint, color master, alkyd paint, epoxy paint series, polyurethane paint, polyurethane curing agent, epoxy curing agent 175, curing agent, epoxy zinc rich primer, printing color paste, polyurethane waterproof paint, gold foil paint

4: Recycled pigment; Recovery of phthalocyanine blue pigment Recovery of permanent purple phthalocyanine green oil soluble butter soluble aniline black aluminum paste fluorescent whitening agent Molybdenum chrome red red lead yellow zinc oxide Lithol red medium chrome yellow benzidine yellow light fast red permanent red gold red permanent yellow chromium oxide green recovery of paint, ink, pigment, plastic pigment, rubber pigment, Ciba pigment, Clariant pigment, essence pigment, iron oxide red Iron oxide yellow pearl powder

5: Recycling electroplating additives; Recovered stannous sulfate, stannous chloride, stannous oxide, zinc oxide, copper chloride, copper sulfate, nickel sulfate, cuprous oxide, chromic anhydride, lithium carbonate, lithium hydroxide, cobalt sulfate, cobalt oxide, copper gold bar, copper gold powder, anti-corrosion base material, zirconia bead

6: Recycled rubber; Recycled natural rubber natural latex styrene butadiene rubber butyl rubber cis-1,4-polybutadiene rubber EPDM chloroprene rubber nitrile rubber 107 silicone rubber SBS thermoplastic rubber isoprene rubber room temperature vulcanization silicone rubber organic silicone AB rubber fluororubber standard rubber hot melt pressure sensitive rubber plastic particle polyurethane vulcanizing agent Moka boron cobalt naphthenate cobalt neodecanoate cobalt polyisobutene

7: Recycle ABS resin Recycle acrylic resin PMMA polyethylene resin PE resin PP resin POE plastic TPU polyurethane elastomer

8: Recycled plastic additives; PVC paste resin PVC paste resin PVC resin chlorinated polyethylene CPE135A PVC heat stabilizer stearic acid lauric acid antioxidant BHT 1010 168 antioxidant foaming agent ultraviolet absorber antimony trioxide decabromodiphenyl ether antioxidant accelerator light dispersant coke inhibitor CTP calcium zinc stabilizer photoinitiator PVC impact inhibitor nucleating agent PE wax polyethylene wax paraffin polyamide wax zinc stearate epoxy soybean oil AKD alkyl ketene polymer chlorinated paraffin plasticizer magnesium stearate decabromodiphenyl ether, decabromodiphenylethane oleamide, erucamide dibutyl ester dioctyl 9; Recycling of daily chemical raw materials; Carbomer Potassium Iodide Dimethyl Silicone Oil Daily Chemical Flavor Leveling Agent Span-80 Vitamin Gambol Potassium Hydroxide Polyvinyl Alcohol Silane Coupling Agent Palm Wax Soap Particle OP-10 Emulsifier TX-10 Emulsifier NP-10 Emulsifier 6501 Surfactant AES Sodium Dodecyl Sulfate (K12) Glycerol White Oil Amino Silicon Oil Castor Oil Pyrophosphate Copper Maltodextrin D-panthenol star anise oil rose essential oil peppermint oil sweet orange oil lemon oil telulan oil menthol borneol artificial bezoar camphor salicylic acid silicone elastomer gel (polyvinylpyrrolidone K30 K90) citric acid vaseline (nipagin methyl ester ethyl propyl butyl ester) vanillin hydrogenated castor oil CAB betaine D panthenol VE oil washing material sunscreen nut oil

10: Food additive; Aspartame Ansai melon gum carrageenan arabic gum pectin food gelatin xanthan gum white granulated sugar oligofructose cassava starch corn starch distilled monostearate sodium alginate xylitol selenium enriched yeast olive oil, palm oil, soybean oil, rapeseed oil, corn oil, peanut oil, goat oil, jojoba oil, avocado oil, shea butter, vegetable oil, Animal oil, soft white sugar, brown sugar, sodium benzoate, potassium sorbate, melamine

11: Recycle expired ink; Offset printing ink UV offset printing ink BYK wax powder BYK leveling agent BYK333 evka leveling agent BYK dispersant BYK wetting agent Eastman cellulose Dow cellulose adhesive accelerator hydroxypropyl methyl cellulose HPMC redispersible latex powder hydroxyethyl cellulose HEC carboxymethyl cellulose CMC microcrystalline cellulose carbon black vapor phase white carbon black maleic anhydride (maleic anhydride) Trimellitic anhydride trimethylolpropane neopentyl glycol phthalic anhydride phenol triethylenetetramine polyacrylamide resorcinol hydroquinone EVA acrylamide pentaerythritol bisphenol A potassium carbonate organosilicon defoamer organobentonite

12: Solvent recovery; Epoxy diluent glycidyl methacrylate (GMA) H acid cyclohexanone n-butanol ethylene glycol propylene glycol glycerol monoethanolamine diethanolamine triethanolamine ethylene diamine ethylene glycol butyl ether butyl acrylate methyl methacrylate solvent propylene glycol methyl ether polyethylene glycol tallow primary amine dodecyl primary amine ethylene glycol monobutyl ether carbon tetrachloride octamethyl cyclotetrasiloxane DMC

Glass flake mastic and coating are compounded by epoxy vinyl resin and C-glass flake. They have excellent chemical resistance, high temperature wet corrosive gas resistance, extremely low water vapor permeability, small hardening shrinkage, low linear expansion coefficient, temperature shock resistance, small wear coefficient, simple construction, curing at room temperature and easy repair. Glass flake coating is simple in construction and can be applied by brush, roller and high-pressure airless spraying. Surface treatment shall be carried out before coating, and rust removal and roughening treatment shall be carried out by sand blasting and shot blasting after degreasing. Generally, 4 # sand or 20-40 mesh quartz sand is used, and 5-7kg/cm2 compressed air is used to drive the sand particles. The sand particles are sprayed from the nozzle at a speed of 50~70m/s, and the surface meets the SIS Sa2.5 specification. The dust after sand blasting is removed, and the coating is carried out within 8h. Coating is generally carried out in dry weather, with temperature above 5 ℃ and relative humidity below 85%. Use the same resin or glass flake (with smaller particle size) as the primer, with a thickness of 50 microns, and apply glass flake coating after the primer is dry. Pay attention to the following points when painting: a. Fully stir the paint; b. Mixing of coating base material and curing agent; c. Viscosity adjustment; d. Active shelf life; e. Cleaning and maintenance of painting equipment (machinery); f. Glass flake size.

Brick lining of oil storage tanks and storage tanks, storage of chemicals, anti-corrosion of brick lining of towers, pipelines and other equipment in various storage tanks, chemical reactions, mixing and separation processes. It is applicable to anti-corrosion of concrete surface structures such as floors, walls, ceilings, drainage ditches, large wastewater pools, sewage treatment equipment, concrete pools and storage tanks, and mariculture areas in chemical, pharmaceutical, and food plants. Cavitation of vinyl glass flake cement in desulfurization tower In desulfurization system, slurry delivered by circulating pump often contains a certain amount of gas. In fact, the slurry conveyed by the centrifugal circulating pump is gas-solid liquid multiphase flow, and the influence of solid phase on the pump performance is continuous and uniform, while the influence of gas phase on the pump is far more complex and difficult to predict than that of solid phase. When the liquid delivered by the pump contains gas, the flow, head and efficiency of the pump will decline. The larger the gas content is, the faster the efficiency will decline. With the increase of air content, the pump will have additional noise and vibration, which may cause damage to the pump shaft, bearing and seal. Primer painting After sand blasting, the surface shall be primed within 12 hours of a working shift or before visible surface rust spots are generated. If surface rust occurs, the area will be re blown according to the above requirements.

1 Enter the site and customize the scaffold according to the requirements of the construction site to meet the construction conditions. 2 Key points of construction, construction temperature between 15-20 degrees. The humidity shall not be greater than% 80. During construction, the bottom layer, the middle layer and the surface layer shall be constructed first. 3 Sand blasting for rust removal, painting sealing primer within 12 hours after rust removal, glass flake mastic construction after the primer is dry, glass flake mastic construction adopts the plastering method, with a thickness of about 1mm, generally completed in two times, and the latter process is carried out after the layer is dry. (General interval) During coating, hold the knife at a certain angle with the base course, push along the sharp corner of the knife in the direction of the sharp angle, squeeze out the air bubbles of the mortar and the foundation as far as possible, and do not stack and spread the coating along the same direction. 4. Local parts are strengthened with glass fiber cloth, such as lacing wire, internal and external corners, and the whole weld junction, so as to ensure the quality of the anti-corrosion coating at these parts. 5 It is difficult to apply solvent-free epoxy coating for finishing paint, and the use of active diluent and low viscosity curing agent increases the cost. Therefore, high solid epoxy coating is used (the volume solid content reaches more than 80%) It is also an optional environmental protection scheme.

The main feature of sewage and waste water tank is that its storage liquid contains acid-base, toxic and harmful substances, which will produce temperature changes during water treatment, so its anti-seepage requirements are relatively high. In the early days, sewage storage tanks had complex processes, mainly using reinforced concrete and impermeable agent processes, or some using FRP, anti-corrosion paint and other materials to build sewage tanks. In the early 1980s, the foreign chemical sewage industry adopted HDPE anti-seepage membrane as the cushion system of the pool. The main characteristics of sewage corrosion are: 1. water corrosion; 2. The types and corrosivity of corrosive media are complex and changeable; 3. The humidity in the air is high, the concentration of chlorine particles is high, and the concentration of harmful gases such as H2S and NH4 escaping from wastewater is high; 4. Corrosion of various microorganisms, bacteria and algae. In this atmosphere, the anti-corrosion requirements for concrete tanks and steel structures are harsh. The concrete tank shall not only be well treated for seepage prevention, but also be provided with reasonable anti-corrosion measures.

Features of vinyl glass flake cement: it has corrosion resistance, permeability resistance, and corrosion resistance to corrosive sewage, strong acid, strong alkali, salt, etc. The solid content can reach 1-1.5mm in one application. Temperature resistance and chemical resistance are superior to epoxy resin coatings. The construction is convenient, the quality is easy, the defective parts are easy to repair, and the coating protection life is more than 5 years. The coating is cured at room temperature, fast drying, good construction performance, excellent mechanical performance, electrical performance and adhesion. Vinyl glass flake mastic is suitable for flue gas desulfurization and smoke exhaust chimney devices in harsh environments in petrochemical plants, thermal power plants, iron and steel plants, non-ferrous metal metallurgical plants, pulp mills, paper mills, chemical plants, waste incineration plants and other departments. It is applicable to various vinyl glass flake mastics. Features: corrosion resistance, permeability resistance, corrosion resistance to corrosive sewage, strong acid, strong alkali, salt, etc. The solid content can reach 1-1.5mm in one application. Temperature resistance and chemical resistance are superior to epoxy resin coatings. The construction is convenient, the quality is easy, the defective parts are easy to repair, and the coating protection life is more than 5 years. The coating is cured at room temperature, fast drying, good construction performance, excellent mechanical performance, electrical performance and adhesion. Vinyl glass flake mastic is suitable for flue gas desulfurization and smoke exhaust chimney devices in harsh environments in petrochemical plants, thermal power plants, iron and steel plants, non-ferrous metal metallurgical plants, pulp mills, paper mills, chemical plants, waste incineration plants and other departments. It is applicable to the brick lining of various oil storage tanks and storage tanks, the storage of chemicals, and the anti-corrosion of brick lining of towers, pipelines and other equipment in various storage tanks, chemical reactions, mixing and separation processes. It is applicable to anti-corrosion of concrete surface structures such as floors, walls, ceilings, drainage ditches, large wastewater pools, sewage treatment equipment, concrete pools and storage tanks, and mariculture areas in chemical, pharmaceutical, and food plants. Cavitation of vinyl glass flake cement in desulfurization tower In desulfurization system, slurry delivered by circulating pump often contains a certain amount of gas. In fact, the slurry conveyed by the centrifugal circulating pump is gas-solid liquid multiphase flow, and the influence of solid phase on the pump performance is continuous and uniform, while the influence of gas phase on the pump is far more complex and difficult to predict than that of solid phase. When the liquid delivered by the pump contains gas, the flow, head and efficiency of the pump will decline. The larger the gas content is, the faster the efficiency will decline. With the increase of air content, the pump will have additional noise and vibration, which may cause damage to the pump shaft, bearing and seal. Primer painting After sand blasting, the surface shall be primed within 12 hours of a working shift or before visible surface rust spots are generated. If surface rust occurs, the area will be re blown according to the above requirements.

Large amount of recycled rubber raw materials Natural rubber styrene butadiene rubber cis-1,4-polybutadiene rubber EPDM chloroprene rubber butyl rubber chlorinated rubber isoprene rubber acrylonitrile butadiene rubber standard rubber smoke rubber sheet silicone rubber vulcanized silicone rubber room temperature vulcanized 107 silicone rubber fluororubber hot-melt pressure sensitive adhesive polyamide hot-melt pressure sensitive adhesive hot-melt adhesive stick hot-melt adhesive particles EVA hot-melt adhesive edge sealing hot-melt adhesive

Ink Offset Ink Lead Ink Loose Paper Ink Paper Ink Surface Ink Interior Ink Plastic Ink

Recycle chemical raw materials, chemical additives, daily chemical raw materials, daily chemical fragrances, flavors, fragrances, thermoplastic elastomers, SBS elastomers, color masterbatch, copolymerization of formaldehyde, polyformaldehyde surfactant, sodium alginate, organic bentonite, vaseline, sodium dodecyl sulfate, K12 cellulose, sodium hydroxymethyl cellulose, carboxymethyl cellulose, vinyl cellulose, vanillin, menthol, hydrazine hydrate, urotropine, melamine, EDTA, disodium, whey egg

Recovered AES sulfonic acid latex powder starch ether lanolin zinc sulfate anhydrous zinc sulfate polyethylene pyrrolidone myristate sebacic acid trimethylolpropane insurance powder carbon black vapor phase method white carbon black precipitation method Acid neopentyl glycol polyvinyl alcohol polyethylene glycol photoinitiator Nipojin methyl ester guar xanthan carrageenan anaerobic pectin bisphenol A sodium hydroxide flat addition styrene acrylic emulsion

Recovered tannic acid, lauric acid, fumaric acid, salicylic acid, tartaric acid, mannitol, citric acid, hexadecanol, fatty alcohol, adipate, magnesium stearate, oxalate, boric acid, Tweenspan leveling agent, defoamer, dispersant, wetting agent, triethanolamine, fatty alcohol, polyoxyethylene ether, dimethyl carbonate, heat transfer oil, glycerine, silicone oil, gloss oil, hydrogen containing silicone oil, dimethyl silicone oil, amino silicone oil, octamethylcyclotetrasilicon Oxane dimethyl siloxane sodium methyl acetate succinate soybean protein isolate textile auxiliary triethylene glycol iodate epoxidized soybean oil

Cosmetic raw materials, washing materials, soap particles, soap base, ethylene glycol polyoxyethylene ether, ethylene glycol monobutyl ether, paint raw materials, paint additives, rubber color chip, rubber color master, rubber color cake, epoxy potting glue, tamarind gum, methyl maltol, ethyl maltol, coconut oil alcohol, sun resistant peacock blue lake, flaxseed gum, edible pectin, benzyl alcohol, ink, raw materials, paint, solvent Enix dye blue nanocore dye blue nack dye somilon dye