Installation method of flange sealing gasket for shut-off valve and ammonia shut-off valve

Time: 2022-01-07 18:09:30 Source: Yonglong Valve Reading: zero second

Installation method of flange sealing gasket for shut-off valve and ammonia shut-off valve

Teflon gaskets and metal sealing gaskets are the sealing spare parts often used for shut-off valves, ammonia shut-off valves and other valves, and are the materials used to seal pipe flanges and valve flanges. Therefore, how to install the sealing gasket is worthy of our attention. Correct installation can ensure the sealing performance and smooth operation of the equipment, otherwise, the sealing performance of the gasket will be damaged.

When the pressure of shut-off valve and ammonia shut-off valve is 1.6MPa~2.5MPa, RF raised face type flange is usually used, and when the pressure is 4.0MPa, FM concave face type flange is usually used. The overall dimensions and widths of gaskets under different pressures are also different. Normally, the gasket under 4.0MPa pressure is narrower than the 1.6MPa~2.5MPa pressure gasket. For example, the 2.5MPa pressure convex surface of DN50 pneumatic cut-off valve is 10mm, while the 4.0MPa pressure concave surface is 8.8mm. Correct selection of gasket size is conducive to the safety of joint sealing.

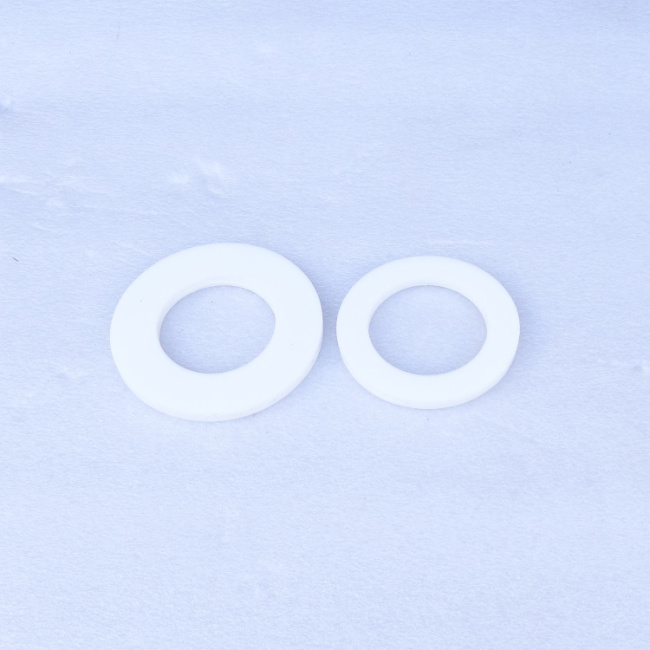

Tetrafluoro sealing gasket for ammonia stop valve Shanghai Yonglong Valve Factory

Installation method of flange sealing gasket of shut-off valve and ammonia shut-off valve:

The correct installation of gaskets shall be carried out when the flange connection structure or threaded connection structure, static sealing surface and gaskets are no doubt after inspection, and other valve parts are intact.

1. Before installing the gasket, the sealing surface, gasket, thread and bolt nut rotating parts shall be coated with a layer of graphite powder or lubricant mixed with engine oil (or water) for graphite powder, and the gasket and graphite shall be kept clean.

2. The gasket installed on the sealing surface shall be aligned and correct without deflection, stretching into the valve chamber or resting on the shoulder.

3. Only one piece of gasket is allowed to be installed, and it is not allowed to install two or more pieces between sealing surfaces to eliminate insufficient clearance between two sealing surfaces.

4. The sealing of the elliptical gasket shall make the inner and outer rings of the gasket contact, and the two ends of the gasket shall not contact the bottom of the groove.

5. For the installation of O-ring, except that the ring and groove shall meet the design requirements, the compression amount shall be appropriate. On the premise of ensuring the sealing, the smaller the compression deformation rate, the better, which can extend the service life of O-ring.

6. Before the gasket is covered, the valve should be in the open position to avoid affecting the installation and damaging the valve parts. The cover shall be aligned and shall not be pushed or pulled to contact with the gasket to avoid displacement and scratch of the gasket.

7. The installation of bolted or threaded gaskets shall keep the gaskets in a horizontal position (for threaded gasket covers, pipe wrenches shall not be used if there is a wrench position).

8. Before the gasket is compressed, the pressure, temperature, medium properties and gasket material properties shall be understood clearly, and the preload shall be determined. The preload shall be as small as possible without leakage during pressure test.

9. After the gasket is tightened, it shall be ensured that the connector has a pre tightening clearance, so that there is room for pre tightening when the gasket leaks.

10. When working at high temperature, the bolts will creep at high temperature, resulting in stress relaxation and increased deformation, which will lead to leakage at the gasket and require hot tightening; On the contrary, at low temperature, bolts will shrink and need to be cold loosened.

11. When liquid sealing gasket is used for sealing surface, its sealing surface shall be cleaned or surface treated. The plane sealing surface shall match after grinding, and the adhesive shall be evenly coated. The air shall be removed as far as possible, and the adhesive layer is generally 0.1-0.2mm.

12. When polytetrafluoroethylene film raw tape is used for thread sealing, the starting point of the film shall be thinned by force and stuck on the thread surface, and then the excess tape at the starting point shall be removed to make the film stuck on the thread wedge-shaped.

Metal sealing gasket of emergency shut-off valve - Shanghai Yonglong Valve Factory

The installation of sealing gaskets for emergency shut-off valve and ammonia stop valve is not complicated, but there are many details that need attention. If the details are handled properly, the installation can be smooth. Whether the installation is correct or not is related to the sealing and operation of the equipment. Therefore, the installation operator should keep the above items in mind and carefully check them during installation.

YoLo Shanghai Yonglong Product: ammonia stop valve, Shut off valve , flame retardant vent cap, liquid ammonia stop valve, electric stop valve, pneumatic stop valve, air drain valve, automatic exhaust valve, low temperature stop valve, Gasket of liquid ammonia valve , Metal gasket of ammonia valve

[Recommended reading] / TECHNICAL ARTICLES