How to select the proper materials for the components inside the control valve

Time: January 11, 2022 11:34:16 Source: Yonglong Valve Reading: zero second

How to select the proper materials for the components inside the control valve

Regulating valve, also known as control valve, is a control element that can change process parameters such as medium flow, pressure, temperature, liquid level, etc. through power operation by receiving the control signal output by the regulating control unit in the field of industrial automation process control. The control valve controls the position of the valve core to change the flow area through the straight stroke actuator structure. The pneumatic control valve with compressed air as the power source and the electric control valve with electricity as the power source regulate the flow and pressure of the valve flow medium.

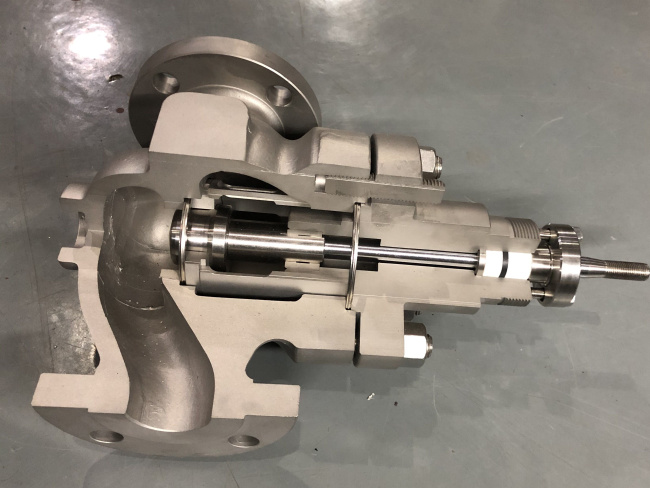

Internal structure diagram of control valve - Shanghai Yonglong Valve Factory

The internal components (stem, disc, sleeve) of electric control valve and pneumatic control valve are usually made of SUS304 and SUS316 stainless steel, and sometimes hardened according to the fluid conditions. According to the normal pressure difference and normal temperature range, hardening treatment is not required. However, if the valve works under harsh conditions for a long time, or the valve seat requires high precision and small leakage, hardening treatment should also be considered. There are several methods for hardening treatment:

1. Heat treatment

SCS24 (17Cr-4Ni precipitation hardening stainless steel)

When the cage valve body is carbon steel or Cr Mo steel, the standard valve internal component material is SCS24, and its corrosion resistance is similar to SCS13. (Standard temperature range - 40 ‐+425t)

SCS440C (17 Cr high carbon stainless steel)

This material is used in hot water or wet steam occasions above 100C. It is an excellent cavitation resistant material, but its corrosion resistance is worse than SUS304. When a corrosive fluid is used, the surface needs Stellite surfacing. (Standard temperature range - 40~+5301)

2. Hardfacing

Stellite surfacing (mainly composed of Co, Cr, W) is a commonly used hardening treatment method with excellent corrosion resistance.

Stellite surfacing can be divided into two methods: full surfacing and local surfacing of sealing surface. In fact, which surfacing method to use depends on the pressure and temperature of the fluid and whether the fluid contains particles. Therefore, there is no specified standard, but it should be determined according to the overall design of the device.

(Standard temperature range: - 195~+800 ^ when the base material is SUS304 and SUS316)

In addition, nickel base alloy surfacing is also used, and its performance and use are the same as that of cobalt base stellite alloy surfacing.

3. Surface hardening treatment

It refers to the use of multi elements (W, Mo, Cr, V, Ti and other metals). The surface hardening treatment shall be carried out for the eutochromide.

(Standard temperature range: low temperature refers to the low temperature and high temperature of the base material+500C).

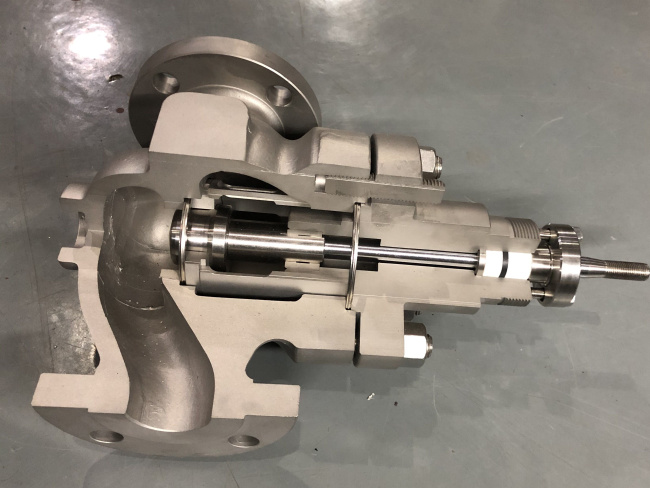

Pneumatic diaphragm single seat regulating valve -Shanghai Yonglong Valve Factory

YoLo Shanghai Yonglong control valve: electric control valve Pneumatic control valve , diaphragm regulating valve, single seat regulating valve, double seat regulating valve, sleeve regulating valve Electric shut-off valve 、 Pneumatic shut-off valve Pneumatic V-type regulating ball valve, fluorine lined regulating valve

[Recommended reading] / TECHNICAL ARTICLES