YongLong insulation jacket bottom valve

Model: FDQL41MOC-16R

Nicknames: tank bottom valve, bus bottom ball valve, diagonal bus bottom valve, bus bottom discharge valve, insulation bus bottom valve, jacket bus bottom valve

Introduction to Pudi Valve:

YongLong slant stem bottom valve is used for discharging materials from reactors, pressure vessels and storage tanks in clean industries such as pharmaceutical biology, fine chemicals, food and beverage, dairy products, etc. The bottom valve has the advantages of no dead angle and leakage for discharging materials, and good sealing performance. When the vessel is using the agitator, when the agitator is opened, the materials at the bottom can fully rotate with the water flow to make the materials stir evenly. The sphere is arc-shaped. When the valve is closed, the spherical arc is consistent with the arc flange at the connecting end, forming no dead angle to avoid material residue.

Use of inclined rod jacketed bottom valve:

Insulation jacket Busy valve is a metal jacket welded on the basis of the Busy valve, which is used to inject heat transfer oil, steam or other heat preservation and cold insulation media to ensure that the media in the valve can work normally. The thermal insulation bottom valve has good thermal insulation and cold insulation characteristics, which can effectively reduce the heat loss of medium in the pipeline. The jacketed bottom valve is mainly used to transport high viscosity medium that will solidify at normal temperature.

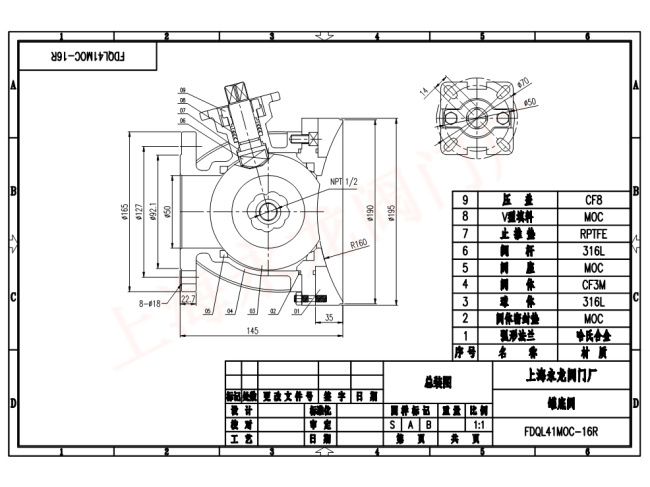

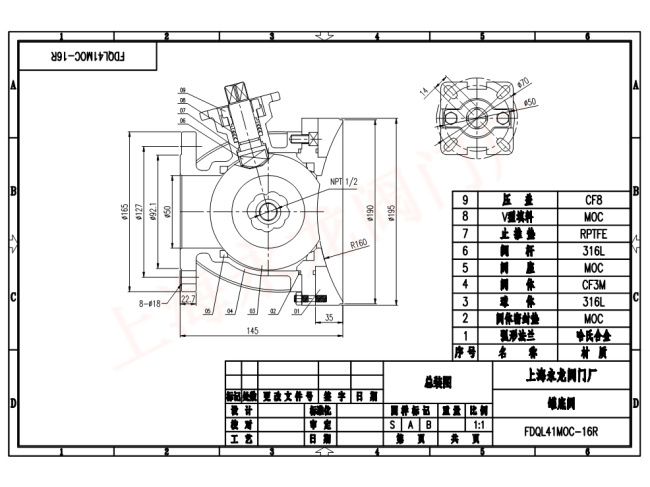

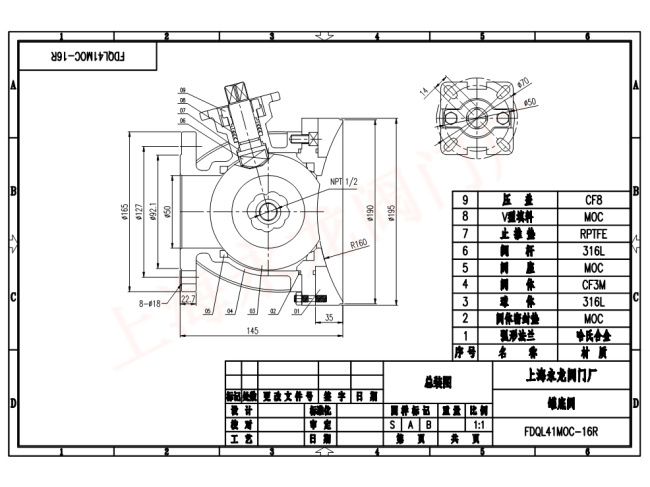

Picture of oblique rod jacket insulation bottom valve - Shanghai Yonglong Valve Factory

Technical features of inclined rod insulation bottom valve:

1. Inclined valve rod: the platform and valve body are inclined at 105 ° to avoid interference between actuator and tank bottom.

2. Platform: ISO5211 standard connection, which can directly install the brake actuator.

3. Arc flange: arc welding flange and valve body form a three piece structure, which is convenient for installation and maintenance.

4. Sphere: When the sphere is closed at 90 °, the sphere is connected with the arc flange to reduce material accumulation.

5. The inner cavity of the valve body is finished, and the material flows smoothly.

6. The gland is equipped with adjusting bolts to adjust the valve stem packing seal.

Use of inclined rod jacketed bottom valve:

Insulation jacket Busy valve is a metal jacket welded on the basis of the Busy valve, which is used to inject heat transfer oil, steam or other heat preservation and cold insulation media to ensure that the media in the valve can work normally. The thermal insulation bottom valve has good thermal insulation and cold insulation characteristics, which can effectively reduce the heat loss of medium in the pipeline. The jacketed bottom valve is mainly used to transport high viscosity medium that will solidify at normal temperature.

Structural drawing of inclined rod insulation jacket bottom valve Shanghai Yonglong Valve Factory

Installation steps of insulation jacket bottom valve:

1. Now confirm the size of the connection part between the arc flange and the tank bottom, and weld the arc flange on the tank bottom after confirming that the size is completely consistent.

2. Screw the connecting bolt onto the arc flange.

3. Insert the seal into the flat groove of the valve cover.

4. Select the correct position of the valve driving part and insert the flange bolt hole in line with the bolt.

5. Ensure that the outer circle of the arc flange is aligned with the outer circle of the valve cover, and the nut corresponding to the screwed flange is flush with the valve cover to complete the installation.

6. Connect the insulation pipe with the jacket interface.

YongLong Pubi valve related products: Pub bottom ball valve - Inclined stem Pub bottom ball valve - Pub bottom discharge ball valve - Pneumatic Pub Bottom Ball Valve - Inclined rod insulated bottom ball valve