Technical parameters: project indicators Color and appearance of paint film: gray, smooth surface, matte Workability: barrier free drying time of paint film: surface dry ≤ 1h, dry ≤ 24h Application period: (23 ± 2 ℃) 5h Impact strength: 50kg/cm Adhesion: metal zinc content in non-volatile matter of grade 1: ≥ 70% Weatherability: (natural exposure for 6 months) no blistering, rust, cracking The non peeling Xinwanteng epoxy zinc rich primer can be customized according to the different zinc content. The zinc content includes 80%, 70%, 60%, 50%, 40%, 30%, etc. The zinc content is different, and the price is different. Please consult Xinwanteng sales personnel for details.

Airless spraying: dilution amount: 0-5% (based on paint weight ratio) Nozzle diameter: 0.4mm-0.5mm Spray pressure: 20MPa-25MPa (200kg/cm2 - 250kg/cm2) * Air spraying: diluent: epoxy series diluent. Dilution amount: 10-15% (by weight of paint) Nozzle diameter: 1.5mm-2.0mm Spray pressure: 0.3MPa-0.5MPa (3kg/cm2 - 5kg/cm2) * Roller coating: diluent: epoxy series diluent Dilution amount: 5-10% (by weight of paint) * Cleaning agent: epoxy series diluent

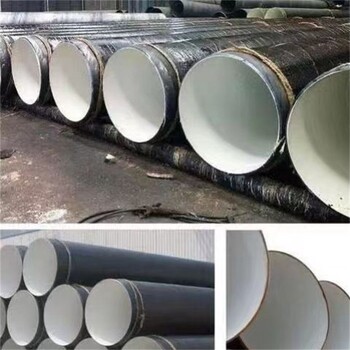

Product Overview This product is a high solid anticorrosive coating composed of modified epoxy resin, glass flakes, corrosion resistant pigments and fillers, additives, solvents, initiators, etc. The component contains a large number of glass flakes, which have strong shielding after film formation, and can effectively prevent the penetration of corrosive media, so as to achieve the purpose of isolation and rust prevention. It is widely used for anti-corrosion of steel pipes, various steel structures, storage tanks and vessels with severe corrosion conditions; And the lining of flue gas desulfurization, denitration, dust removal equipment and flue in environmental protection projects; It is also suitable for corrosion prevention and leakage prevention of various concrete structures as well as wear resistance and waterproof protection. Main features 1. Excellent adhesion and durability, corrosion resistance and impact resistance. 2. It has high water resistance, salt water resistance, oil resistance, alkali resistance, solvent resistance and a certain degree of acid resistance. 3. With high solid content, it can be used as thick film coating, and the thickness can reach 100-120um at one time. 4. The coating has high hardness and strong wear resistance, and is suitable for alternate dry and wet, dark and humid environments. 5. The construction is convenient, the operation is simple, the quality is easy, the defective parts are easy to repair, and the coating protection life is more than 8 years. 6. The coating is cured at room temperature, with fast drying speed, good construction performance, and excellent physical and mechanical properties, electrical properties, and cohesiveness.