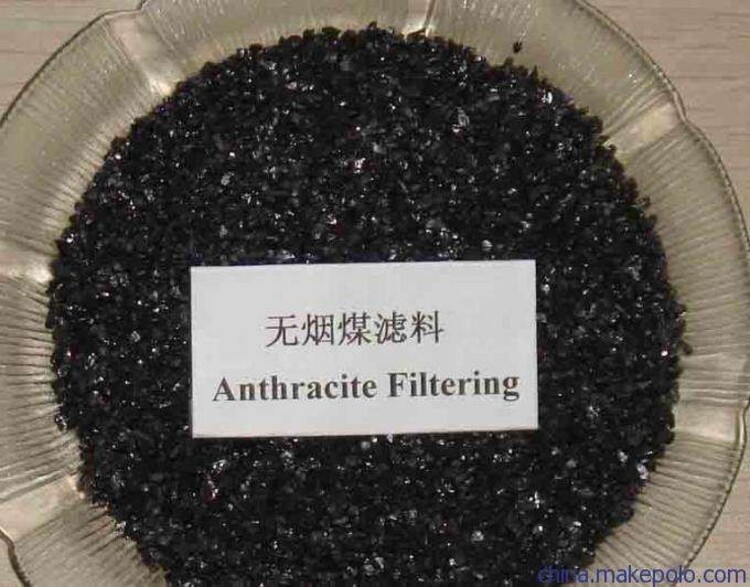

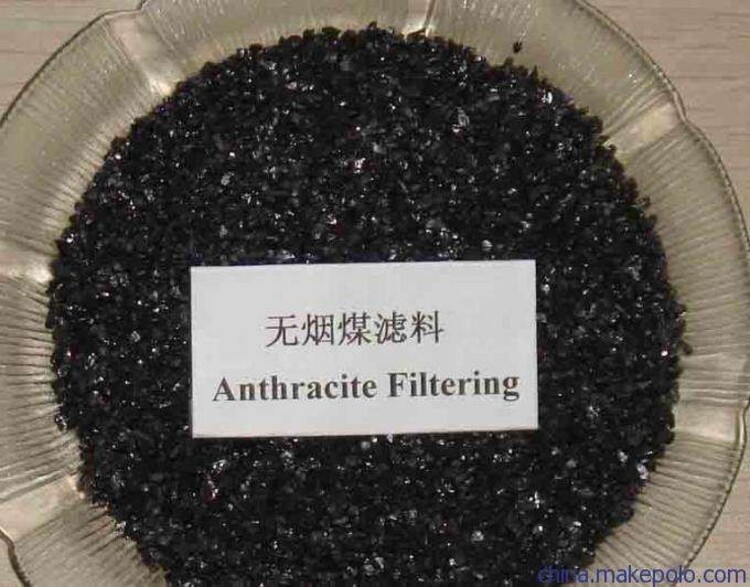

Water filtered anthracite, also known as activated carbon, is a commonly used water treatment material. After high-temperature carbonization and activation treatment, anthracite has a high microporous structure and adsorption capacity, which can effectively remove organic matter, odor, pigment, heavy metals and other pollutants from water. Therefore, water filtered anthracite is often used in domestic and industrial water treatment systems to improve water quality and make water cleaner and safer.

Anthracite filter material is a kind of filter material used in the water treatment industry. It is made of anthracite as raw material through the process of fine crushing, powder, screening, etc. It is a commonly used double-layer, three-layer fast filter material. Anthracite filter material is an important layer of three layers of filter material, because it is directly facing sewage and is the layer of filter material for filtering sewage. If the thickness of anthracite filter material cannot be accurately mastered, unnecessary losses will be caused.

[Technical Requirements for Anthracite Filter Media]

① The sum of crushing rate and wear rate shall not be greater than 3% (the percentage is calculated by mass, the same below).

② The average density of anthracite filter material is generally not less than 1.4g/cm3 and not more than 1.6g/cm3.

③ Anthracite filter material shall be free of visible soil, shale and foreign debris. The mud content of anthracite filter material shall not be greater than 3%, and the density shall be greater than 1. The content of 8g/cm3 should not be more than 8%. ④ The hydrochloric acid solubility of anthracite filter material shall not be greater than 3.5%.

Anthracite filter material is specially selected from deep well minerals, with high carbon content percentage. Anthracite filter material is classified manually, which can reduce irrelevant minerals and ash content. It is also filtered and washed. Anthracite filter material is specially selected from deep well minerals, with high carbon content percentage. The water filter material is classified manually, which can reduce irrelevant minerals and ash content. The water filter material is also filtered and washed to ensure that it is suitable for water filtration. Due to its good solid particle retention capacity, anthracite can reliably improve the removal capacity of suspended particles. In addition, its uniformity coefficient is low, which helps to speed up the flow velocity.

Technical indexes of anthracite filter material produced by our plant

Mud content% ≤ 4 Fixed carbon% ≥ 80%

Specific gravity g/cm3 1.4 ~ 1.6 Volume weight g/cm3 0.947

Wear rate% ≤ 1.4 Void rate% 47 ~ 53

Crushing rate% ≤ 1.6 Solubility rate of hydrochloric acid% ≤ 3.5

The anthracite filter material for water purification is a good and ideal filter material widely used in China at present, with a wide range of uses and applications. It can be used for water quality treatment before and after production of domestic drinking water, industrial production water, various double-layer and three-layer filters, various double-layer and three-layer multi-media filters, chemical industry, metallurgy, thermoelectric, pharmaceutical, paper making, printing and dyeing, food, etc. Anthracite filter material features good luster, spherical shape, high mechanical strength, good compression resistance, stable chemical performance, no toxic substances, abrasion resistance, and insoluble in acid, neutral and alkaline water. In addition, the surface of anthracite particles is rough, with good adsorption capacity, large porosity (>50%), high contaminant capacity, and low backwash strength due to light weight, It can save a lot of backwash water and power. It is used together with quartz sand filter material, which is a good material for double-layer rapid filter, three-layer filter and filter tank filtration currently promoted in China. It is an effective way to increase the filtration rate, increase the water output per unit area, double the sewage interception capacity, reduce the project cost and reduce the floor area. Anthracite filter material is classified manually, which can reduce irrelevant minerals and ash content. It is filtered and washed to ensure that it is suitable for water filtration. Due to its good solid particle retention capacity, anthracite can reliably improve the removal capacity of suspended particles. In addition, its uniformity coefficient is low, which helps to speed up the flow velocity. The production process of anthracite filter material is processed by carefully selecting crushed coal, powder, screen and other processes. It is packed in plastic woven bags of 50kg each. Keep in a cool and dry place, not exposed to the sun. Production specification: Yubairun purified water 0.5-1mm, 0.8-1.2mm, 0.8-1.8mm, 1-2mm, 2-4mm, 4-6mm.

Description of standard anthracite filter material:

The standard anthracite filter material is made of carbon blocks after selection, crushing, screening and processing. It has a good gloss appearance and is in the shape of polygonal particles. It is generally used for double-layer and three-layer filtration.

Description of TJP anthracite filter material:

TJP type anthracite filter material is produced according to the standards of Japan Shuidao Jushi Association, and its quality fully meets the Japanese standards. It is mainly used for steel rolling circulating water treatment of iron and steel system and advanced treatment of petrochemical industry sewage, as well as water filtration in precision manufacturing, aerospace and navigation.

Common specifications: 0.8-1.2mm, 0.8-1.8mm, 1-2mm, 2-4mm, etc.

Service life of anthracite: water quality directly affects the service life of anthracite. It can be used for two to three years. It can be extended to five to ten years if a part is replaced every year depending on the situation