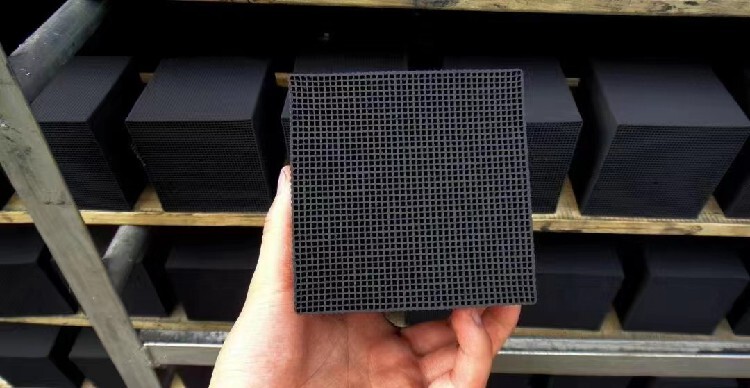

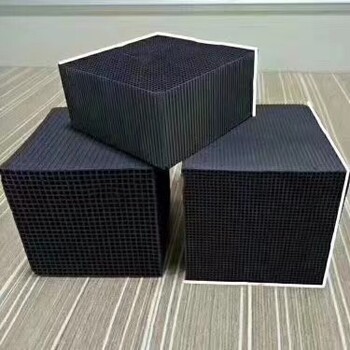

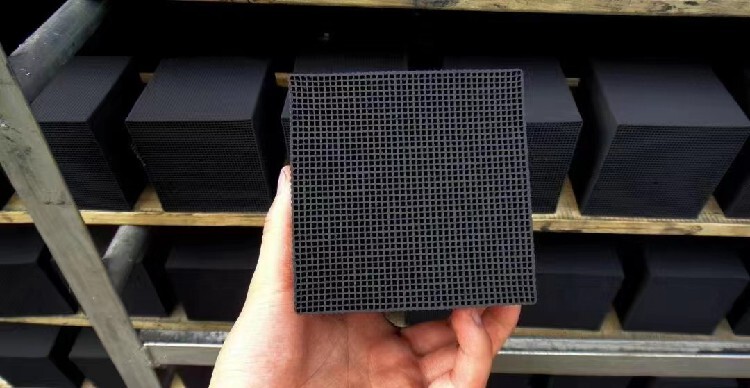

See the density: the more pores, the higher adsorption performance. It is recommended to buy activated carbon products with small density, light hand feel and large volume. 2. Particle size: the smaller the activated carbon particles, the larger the air contact area and the larger the specific surface area, and the better the adsorption performance. It is recommended to select activated carbon products with particle diameters between 0.42-0.85mm. 3. Components: activated carbon absorbs harmful gases by pore size. Different harmful gases have different molecular weights,

Generally, activated carbon only has a simple adsorption function. The adsorption taste is OK, but it will be saturated. Another formaldehyde removal product, Ye Guangni, has the function of adsorbing, locking and decomposing harmful substances. It was used by NASA for the decomposition of harmful gases in the early days, and was later used for the removal of indoor formaldehyde and decoration pollution for civil use. It is an epoch-making material product application, which is more expensive than activated carbon in price. Formaldehyde removal materials with porous structure are based on attapulgite and sepiolite, added with diatomite, tourmaline and other natural minerals, and made by special processing technology. They are polar molecules, benzene, and ammonia. 98 nanometers in crystal arrangement. At the same time, it has weak electricity, formaldehyde, and the pore diameter of its internal pores makes it have the characteristics of absorbing formaldehyde, benzene, TVOC and other harmful gases

Which kind of activated carbon is good?

Mainly used for formaldehyde removal, bamboo charcoal, coconut shell, large pieces and bulk, round, broken, which is better?

Compared with the photocatalytic oxidation method, the chemical adsorption method has the advantages of easy operation, less investment, easy access to adsorbent, renewable, no secondary pollution, etc. Chemisorption is the process of electron transfer, exchange or sharing between adsorbate molecules and solid surface atoms (or molecules) to form new chemical bonds. Carbon based adsorbents, represented by activated carbon, are widely used in the adsorption field because of their large specific surface area, rich oxygen-containing functional groups and low cost.

The chemical adsorption of adsorbent mainly uses its surface oxygen-containing functional groups to oxidize pollutants such as formaldehyde into harmless substances, and can effectively increase the number of oxygen-containing functional groups through physical or chemical activation. Tang Jinhua and others investigated the influence of oxygen containing functional groups on the adsorbent surface on the removal of formaldehyde. The results showed that the increase of oxygen containing functional groups was conducive to improving the adsorption effect of the adsorbent. The comparison between physical adsorption and chemical adsorption proves that chemical adsorption is better than physical adsorption. Gu Cheng et al. used phosphoric acid as an activator in their research on the adsorption of formaldehyde by composite materials. The results showed that the activated adsorption materials had a large number of oxygen containing functional groups and polar functional groups, and had a high adsorption capacity for formaldehyde. Although the adsorption performance of formaldehyde depends on the number of oxygen containing functional groups on the surface of the material, the research has not explored its chemical adsorption mechanism in depth.

The capacity of chemisorption is not only limited by the number of oxygen containing functional groups on the adsorbent surface, but also closely related to the active components of the material. The research shows that the adsorption performance of the modified adsorbent is greatly improved, which is mainly due to the change of the type and number of functional groups on the surface of the adsorbent and the increase of active components. The main methods of adsorbent modification include: strong reduction modification, strong oxidation modification, acid-base modification and metal modification.

Six common quality standards of wooden activated carbon

During the application of wooden activated carbon, both the user and the user will test various indicators of wooden activated carbon. One is to judge the quality of wooden activated carbon products, and the other is to determine which type of activated carbon to use based on this. What kind of wooden activated carbon is the high-quality activated carbon? It is very simple for people inside the industry, but for people outside the industry, every other line is like a mountain. Let's introduce the quality standard of wooden activated carbon. After understanding, we believe that if you purchase wooden activated carbon according to this standard, the quality of the activated carbon you purchase will not be poor.

The quality standard of wooden activated carbon is usually from the aspects of appearance, iodine value, particle size, specific surface area, mechanical strength, ash content, etc.

Wood activated carbon

The appearance of wooden activated carbon is black irregular sheet or granular, with a little black powder on the surface.

Iodine value has always been the quality standard to judge the adsorption capacity of activated carbon. The higher the iodine value, the stronger the adsorption capacity. The iodine value of wooden activated carbon is usually above 600.

Generally, the particle size of commonly used wooden activated carbon is 10-24 mesh, and the particle diameter is 2.0-0.8 mm, with a size error of 5%. The smaller the particle size, the better the quality of wooden activated carbon.

The specific surface area is to open the internal space of one gram of wooden activated carbon into a plane. The plane area is the specific surface area of wooden activated carbon. The quality of wooden activated carbon with a larger specific surface area is better.

Six common quality standards of wooden activated carbon

Mechanical strength determines the service life of wooden activated carbon. The higher the mechanical strength, the higher the strength, the better the quality and the longer the service life of wooden activated carbon. The strength of wooden activated carbon is generally required to be greater than 80%.

Ash is the residual residue of pulverized carbon after burning for 3 hours at 954 ℃. It refers to the weight percentage after a certain amount of activated carbon is oxidized. The ash content of wooden activated carbon is mainly the residue after burning the wooden activated carbon. The lower the ash content, the more standardized the burning process of wooden activated carbon, the less the residue.

The above are six common standards for wooden activated carbon summarized by Yongruida activated carbon manufacturers. There are many quality standards for wooden activated carbon. Only through comprehensive comparison in all aspects can we ensure the products of wooden activated carbon

Activated carbon bags can appear in many scenes in daily life, such as cars, wardrobes, offices, etc. However, most people simply consider the packaging and price of activated carbon, thus ignoring the important factor of quality. In fact, after seeing the analysis of Sandaile, you will find that it is not so difficult to distinguish the advantages and disadvantages of activated carbon, and it is not only people who can operate it.

Activated carbon is a kind of black and porous solid carbon, which is produced by crushing, molding or carbonization and activation of uniform coal particles. The main component is carbon, and contains a small amount of oxygen, hydrogen, sulfur, nitrogen, chlorine and other elements. The specific surface area of ordinary activated carbon ranges from 500 to 1700 m2/g. With strong adsorption performance, it is an industrial adsorbent with wide applications

The coal granular activated carbon is made of anthracite as raw material and refined by the process, and its appearance is black amorphous particles. It has the advantages of developed void structure, large specific surface area, strong adsorption capacity, high mechanical strength, small bed resistance, good chemical stability, easy regeneration, etc.

Rice husk activated carbon

The rice husk produced during rice threshing is often thrown away as waste. Japanese researchers recently reported that they have developed the technology of making activated carbon from rice husk.

Professor Hideki Saito of Nagaoka University of Technology and Science in Japan pointed out in his paper that if rice husks were simply heated to make carbon, the residual silica in rice husks would prevent them from functioning as active carbon. However, the above "rice husk carbon" can be successfully removed by mixing it with potassium hydroxide and sodium hydroxide, and then conducting heat treatment. It is estimated that the surface area of the rice husk activated carbon and its pores is 2.5 times of that of the ordinary activated carbon.

Activated carbon fiber

This product is made of coconut shell powder activated carbon as the adsorption material, which is adhered to the non-woven fabric substrate with polymer bonding materials. It can effectively absorb various industrial waste gases, such as benzene, toluene, xylene, formaldehyde, ammonia, sulfur dioxide, etc. It is mainly used to make activated carbon masks, and also can be used as insoles. It is widely used in chemical, pharmaceutical, paint and other industries, and has remarkable anti poison and deodorization effects.

Activated carbon

See decolorization ability: another performance of activated carbon adsorption ability is decolorization ability. Activated carbon has the ability to turn colored liquid into light color or colorless because it absorbs pigment molecules in colored liquid.

The specific method is to add 100ml pure water and 20 drops of red ink into a transparent cup. (Any pigment that is easy to observe but does not change the nature of water can be used here, such as blue ink, printer color ink, but ink and carbon ink cannot be used).

After mixing evenly, divide them equally into another same cup, then pour the same amount (about 10g each) of the two activated carbons to be compared into two cups respectively, mix for 2 minutes, then immerse both ends of folded tissue paper into two cups respectively, take out and compare the color: those that are red are inferior activated carbons; The lighter the color, the stronger the adsorption capacity of activated carbon; If it is completely colorless, it is activated carbon. What are the characteristics of activated carbon? What are its applications?