Phenolic epoxy resin is a kind of low molecular weight synthetic resin with moderate viscosity, high temperature resistance, good adhesion, adhesive, anti-corrosion, casting, mechanical and other properties, which is widely used in composite materials, UV curable solder resist ink, temperature resistant vinyl resin and coatings; Phenolic epoxy resin not only has the characteristics of high heat resistance and corrosion resistance of phenolic resin, but also has the characteristics of good adhesion of epoxy resin, good mechanical and physical properties, and good electrical insulation performance. It can be used in coatings and adhesives that need to improve the heat resistance grade or corrosion resistance.

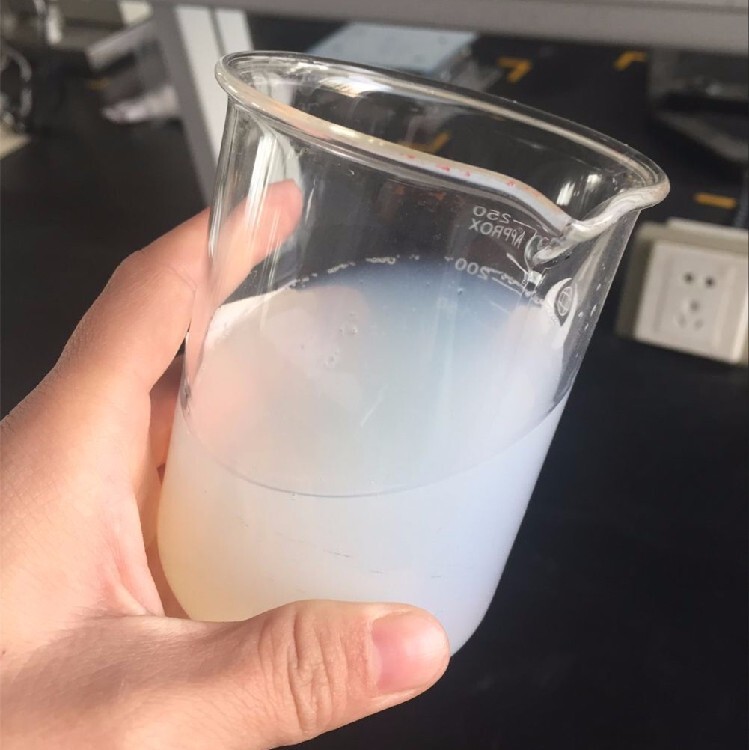

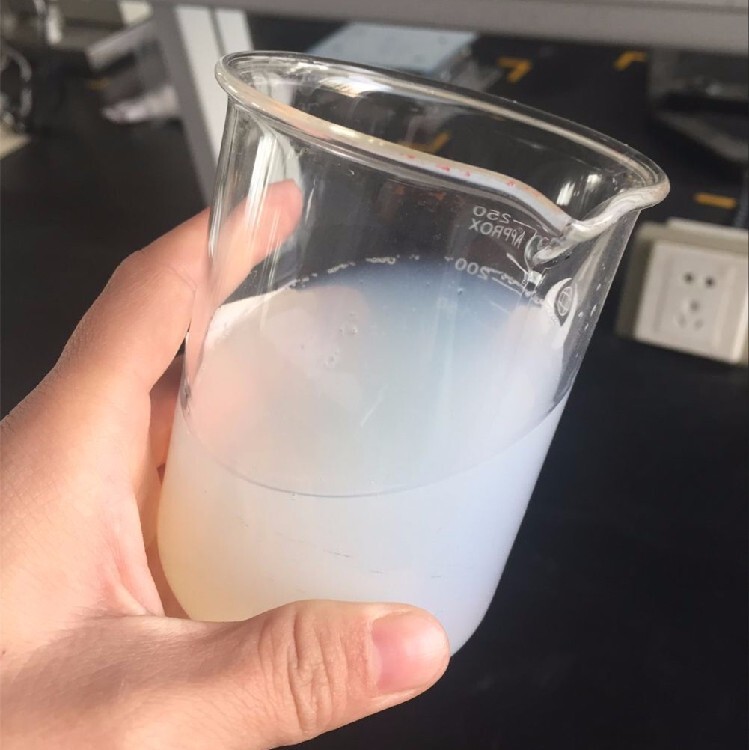

There are three types of water-based: emulsion type, water dispersible type and water-soluble type. Among them, the water-soluble type has a particle size of 5 nm and a transparent appearance; The water dispersible particle size is 20~100 nm, and the appearance is translucent; The particle size of the emulsion is 100 nm, and the appearance is emulsion. Formation principle of water-based photosensitive resin: as for emulsion type, external emulsifier was used in the early stage. The oligomer does not contain hydrophilic groups. By mechanical action, the oligomer is dispersed in water to obtain oligomer emulsion; However, the addition of emulsifier affects the water resistance and mechanical properties of the cured film, and the material is also sensitive to DH value. At present, self emulsifying type is mostly used, that is, hydrophilic groups (such as carboxyl group and polyethylene glycol) are introduced into oligomers, which can self emulsify in water without adding emulsifiers. After curing, water resistance and. The formation principle of water dispersion type is to use the clever balance of hydrophilic and hydrophobic groups in oligomer to form a stable water dispersion after dispersion in water. The water-soluble type is to use oligomers containing sufficient carboxyl salt or quaternary ammonium salt groups to become water-soluble materials. Basic properties of water-based photosensitive resin: adhesion: water-soluble water dispersible emulsion Curing speed: water-soluble water dispersible=emulsion After film forming Surface properties: water-soluble water dispersible emulsion After film forming Water resistance: water dispersible water-soluble emulsion

The high weather resistance resin and the main resin in the synthetic resin tile have very good corrosion resistance, and will not be easily eroded by rain and snow, resulting in performance degradation. It can resist the corrosion of acid, alkali, salt and other chemicals for a long time, so it is very suitable for coastal areas with strong salt fog corrosion and areas with serious air pollution.

Construction process of structural crack repair grouting: 1. Requirements for crack cleaning, dry and free of oil stain and dust; 2. Requirements for base pasting, which is used to seal cracks and bond the base in the construction of concrete structural crack repair grouting; Take 100 parts of material A and 3 parts of material B (curing agent). Mix and mix well before use. 【 It is not easy to mix more than 0.5kg at a time, and the mixing measurement will be increased according to the actual situation after proficiency 】. When pasting the base, the gap between the base and the base should be centered. At the same time, the gap between the base and the base should be coated with sealant until the gel is completely hardened, and grouting should be started. III. I. Material allocation: 1. Mix and mix evenly according to the proportion of A: B=4:1 before use. 2. According to the actual crack width and construction conditions on site, an appropriate amount of diluent (such as:, II, or resin diluent) can be added into the epoxy resin mixture for dilution to reduce the resin viscosity and facilitate grouting. 3. The one-time mixing amount should not exceed 500g. It should be used as soon as it is prepared. The initial setting time should be 24h and the full curing time should be 5-7 days. If the one-time mixing amount is too large, the initial setting time will be shortened accordingly. When the grouting stops, the grouting machine shall be cleaned with industrial alcohol for reuse. If the pressure of the grouting machine is insufficient or leakage occurs, the grouting machine shall be replaced with a new one.

Weather resistance: durable color, low temperature resistance, corrosion resistance, difficult combustion; ASA is a weather resistant engineering resin, which has super long durability in natural environment. As the surface material of synthetic resin tile, it can maintain the stability of physical and chemical properties and maintain the brightness of color even if it is exposed to ultraviolet rays, moisture, high heat, low temperature and other adverse conditions for a long time. According to the outdoor use results in areas with strong sunlight, such as Arizona and Florida, the color change Δ E5 in ten years can be ensured.

Resin tile, a new material, will soon replace the tedious construction of old style bricks and tiles, which can no longer conform to the development trend of ancient bricks and tiles in terms of construction efficiency or integrity. The old style tile products are updated from time to time, making the construction efficiency and the integrity after completion very good. The decomposition resin tile should be said to be one of the tile products today. The future roof building materials will be the world of new roof tile decomposition resin tile. With the increasing progress of the national level to slope project, ASA decomposition resin tile has more and more advantages, and decomposition resin tile roof building materials are just around the corner. The decomposed resin tile is a new type of construction material developed by using high and new chemical technology. It has many characteristics, such as light weight, high strength, waterproof and moisture-proof, anti-corrosion and flame retardant, sound insulation and heat insulation, and is generally applicable to the construction of residential villas, awnings, sunshades, and antique buildings in the development zone, agricultural markets, shopping malls, residential quarters, and Xinxiang Village. High weather resistance modified resin (ASA) is selected as the surface material of decomposition resin tile. This high weather resistance resin is very suitable for outdoor use. It has extraordinary durability in the natural environment. Even if it is temporarily exposed to ultraviolet light, moisture, heat, cold and impact, it can still adhere to the fluctuation of color and physical feeling performance.