Henan Huineng Road and Bridge Technology Co., Ltd., founded in 2008, is a high-tech company engaged in the research and development, production, sales and construction of new road maintenance materials, the production and research base of the Ministry of Transport's Academy of Highway Sciences, the director unit of the Management and Maintenance Branch of China Highway Society, and Huineng products have passed the ISO9001 international quality system certification.

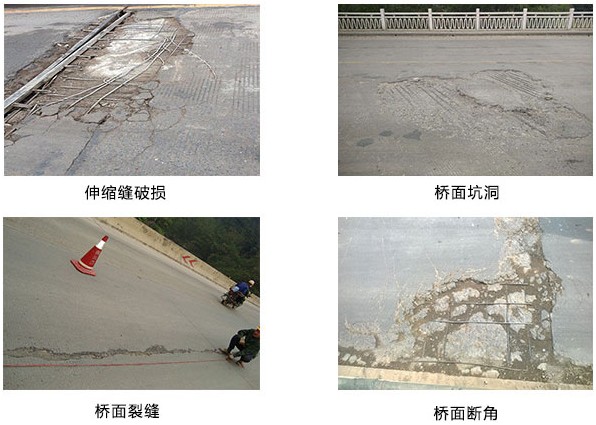

Huineng is a domestic company that can systematically solve the problems of deep structure and surface layer of cement concrete pavement. For the repair of bridge pavement and bridge expansion joint concrete, it can restore traffic in one hour! Provide system scheme and scientific and technological support for reconstruction, repair and maintenance of highways, national roads, provincial roads, municipal works, and county and township roads. The repair effect is beautiful, the quality is stable, fast and efficient, the traffic congestion is reduced, and the project cost is reduced!

In 2015, "Huineng" brand concrete road rapid repair materials were listed as the brand recommended by the national inspection bureau, China's road maintenance technology innovation enterprise, China's famous brand in the road building materials industry, and China's 100 honest enterprises.

In 2018, the company's chief editor participated in the official release and implementation of the national standard specification JT/T 1211.1-2018, Quick Repair Materials for Cement Concrete. Establish industry standards to promote the healthy and standardized development of the industry in the future.

The company has 6 sets of technologies: 1. UHPC ultra-high performance concrete technology; 2. High ductility concrete, grouting, grouting and reinforcement technology; 3. Military protection technology; 4. Concrete anti crack and anti-seepage additive technology; 5. Road, bridge and tunnel repair and reinforcement technology; 6. Concrete durability protection technology.

More than ten years of precipitation, casting brilliant. Huineng Road&Bridge Technology has grown into a leading enterprise in the rapid repair and reinforcement industry of cement concrete roads, bridges and tunnels. Six core businesses of the company: trenchless reinforcement of subgrade, rapid slab replacement of pavement, surface repair of pavement, repair of deep structure of pavement, repair and reinforcement of concrete structures, and permeable concrete binder for sponge city. The road, bridge and tunnel maintenance materials and technologies of Huineng Company are widely used in the renovation and reconstruction projects of airports, ports, high-speed railways, rail transit, water conservancy, highways, national and provincial roads, municipal roads, township roads, factories, parking lots, gas stations, residential areas and other roads, as well as industrial/civil buildings and other infrastructure projects. With the advantages of reliable quality, fast efficiency, energy conservation and environmental protection, it has won a good reputation in the market.