In December 2023, the Ministry of Industry and Information Technology issued the Opinions on the Implementation of Excellent Quality Engineering in Manufacturing Industry, emphasizing that quality is the lifeline of the manufacturing industry, and promoting the industry from quantity expansion to quality improvement is the practical need for high-quality development of the manufacturing industry in the new era.

In this process, the level of factory intelligence in the manufacturing industry continues to improve. For example, in the field of industrial product testing, engineers turned AI into "new workers" to help factories solve those thorny problems.

Although the manufacturing industry has used data acquisition equipment such as industrial cameras to detect products for a long time, the collected data still needs to be identified and judged manually, which is inefficient and difficult to guarantee the quality stability.

The breakthrough of machine learning algorithm provides a possibility to train AI model based on the accumulated data in the past, and then let it independently judge the relevant detection data of production line, thus overcoming the low efficiency and high error rate of manual judgment. Thus, AI+ machine vision , opening a gap for industrial intelligence.

What is machine vision?

According to the definition of American Association of Automatic Imaging (AIA), machine vision is a combination of hardware and software applied to industrial and non industrial fields. It provides operation guidance for equipment to perform its functions based on captured and processed images.

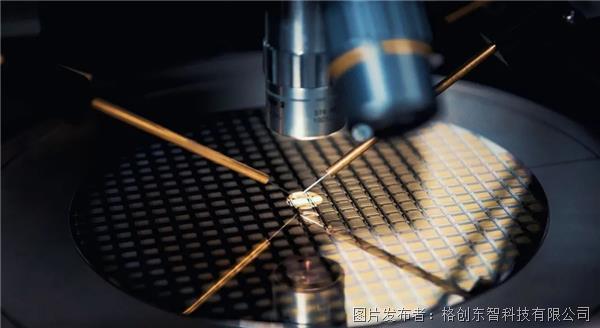

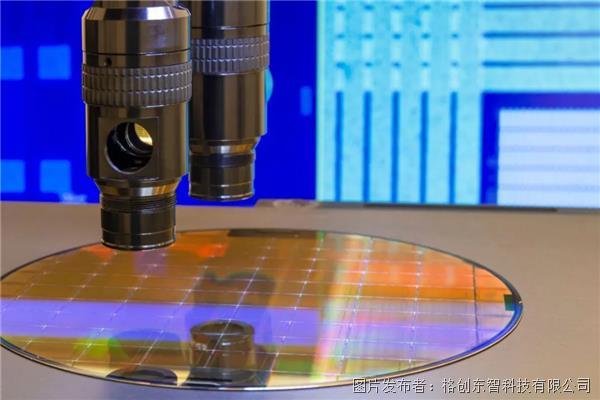

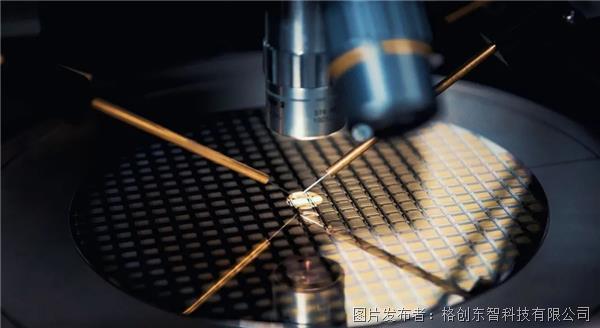

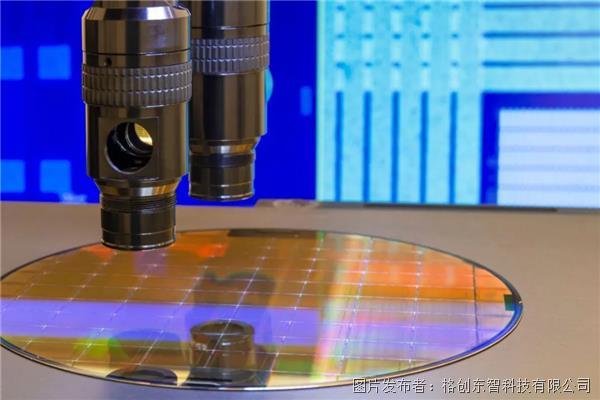

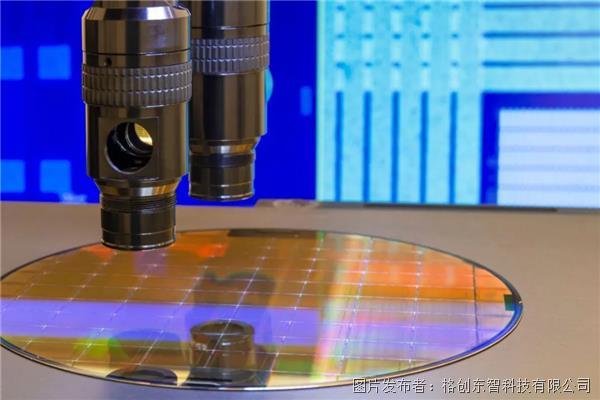

Machine vision can be divided into two parts: imaging and image processing analysis. Imaging depends on hardware components of machine vision system, such as light source, light source controller, lens and camera; Image processing and analysis is based on the imaging, through the visual control system.

The core functions of machine vision system include recognition, measurement, positioning and detection.

The difficulty of the above functions is increasing step by step. Therefore, production inspection is also one of the fields that can best demonstrate the "power" of machine vision.

At present, machine vision technology has been widely used in consumer electronics, automobile manufacturing, semiconductor, photovoltaic and other fields, and the market scale is expanding.

AI visual inspection from semiconductor manufacturing scene

In 2018, Gechuang Dongzhi was incubated by TCL and developed a series of related products and solutions based on TCL's accumulated digital capabilities in solving specific problems.

Deep industry Knowledge How has become the natural advantage of Gertrong Dongzhi. Unlike some AI enterprises, which seek scenarios and customers with technology, they are the result of specific scenarios, so once they are born, they have the gene to understand scenarios and customer needs well.

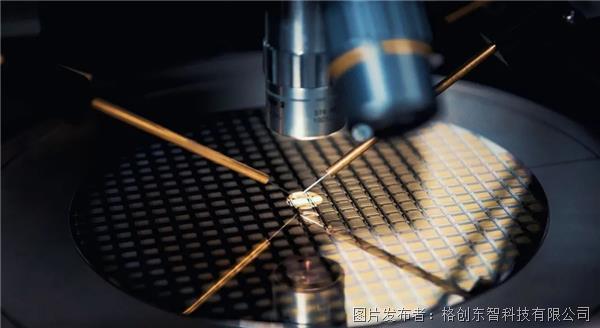

The machine vision inspection scheme of Gertron Dongzhi - Tianshu AI vision inspection system is a small branch of its industrial intelligence solution, which originates from the production inspection of semiconductor panels of TCL Huaxing.

Every key process of panel production requires AOI (Automatic Optical Inspection) equipment to take pictures to identify relevant defects. In the early stage, defects are classified manually. Only after classification, can we know what to do next. There are more than 100 processes in the whole process, which requires a lot of manual work to do each key process.

After the rise of machine vision technology, Gechuang Dongzhi and TCL Huaxing developed the AI visual inspection system to identify and classify pictures based on artificial intelligence technology.

After the implementation of the scheme, first of all, the detection efficiency has been greatly improved, which can replace 80% and 90% of the detection personnel, and can detect nearly three million pictures a day. Secondly, it improves the detection accuracy, because it can effectively avoid the problems of fatigue and cognitive differences between people.

Since then, with the improvement of technology maturity, Gertrong Dongzhi's machine vision scheme has gradually spilled out from the semiconductor industry. At present, it has successfully enabled 22 sub industries, including photovoltaic, 3C electronics, household appliances, petroleum and petrochemical, aerospace, etc.

How can AI model enable manufacturing?

The process of AI enabling machine vision inspection has gone through a path from small model to large model, and then to "small model".

At the initial stage, Gechuang Dongzhi first combined deep industry data accumulation and in-depth understanding of specific industrial scenarios and detection indicators, and then combined machine learning algorithms to build a small model for specific detection scenarios.

The construction of small models aims to closely match specific business scenarios and requirements, emphasizing pertinence and high adaptability. Through the focused and customized development process, the small model can improve the operation efficiency and decision-making quality while meeting the specific needs of the industry.

However, small models have the risk of over fitting, that is, the model focuses too much on the details and noise in the training data set, so that it does not perform well on new and unknown data. This makes the premise of its implementation is that the data must be standardized and standardized to make the data distribution and proportion reach the best state. The development and tuning of the model requires the participation of professionals, who are required to be familiar with both AI technology and industry expertise.

Many customer enterprises do not have such talent reserves.

In 2022, the breakthrough of large model technology will bring hope to solve the above problems.

Compared with small models, large models have stronger compatibility and stability. The design of the large model is not limited by the complexity of the data, and does not need to understand the scene too deeply. It only needs enough data for training, and does not need too much parameter adjustment or architecture design. While processing various types of data more easily, the phenomenon of over fitting will not occur.

In summary, the emergence of large models can significantly reduce the threshold for model landing.

GTZ, which has long considered how to make the machine vision system better and easier to land, actively responds to the technological trend of large models, and trains and develops its own large models based on a large amount of existing data and small models.

However, there is a new problem to directly land the large model on the customer side. It is difficult to meet the seamless connection between continuous rapid detection and production processes due to the high resource consumption and cost pressure of reasoning requirements in real-time industrial scenarios.

The solution of Gechuang Dongzhi is to train large models internally first, and then carry out "model slimming" for specific scenes. The advantage of this is that using large models to learn and extract features can train small models more efficiently, and the amount of data required in the training process is also greatly reduced, making the landing application of models more convenient and feasible.

In addition, in order to improve product delivery, Tianshu AI visual inspection system has also developed a visualization function. By simplifying the model development process into intuitive drag and drop operations, ordinary IT personnel who are not AI experts can easily develop and optimize AI models.

Customers can choose from a series of preset submodels and algorithms, and combine them through simple operations to build a model that meets specific needs without in-depth understanding of the complex algorithm details behind. In this way, many customer enterprises can enjoy the latest machine vision technology without additional huge labor costs.

How much does AI affect the process of industrial intelligence? In addition to the field of machine vision, industrial intelligence applications can effectively improve product quality and lead the digital transformation and upgrading of the manufacturing industry through precision control, intelligent analysis, automated production, quality traceability and other means.

Improve quality with "intelligence" and lead a new era of industrial intelligence. In the journey of realizing new industrialization, Gertrong Dongzhi will continue to give play to its technological advantages, and is committed to transforming more digital application achievements integrating software and hardware into practical productivity, injecting new momentum into high-quality development, and exploring the infinite possibilities of industrial intelligence.