In recent years, China's fine chemical industry has continuously increased its investment in technological innovation, improved product quality and technology content, and promoted the industry to high-end development, so as to improve the international competitiveness of domestic fine chemical products. Therefore, enterprises need to constantly improve their own management level, including production scheduling, production management, accounting management, human resources management, etc, Improve the comprehensive competitiveness of enterprises.

Recently, Beijing Hollysys Optimization Technology Co., Ltd. (hereinafter referred to as Hollysys Optimization Company) has incubated a fine chemical enterprise APS+project. At present, the enterprise mainly relies on manual or tabular methods for workshop scheduling. Faced with problems such as unbalanced production capacity of each line and frequent line changes, the enterprise hopes to improve order delivery rate and equipment utilization rate to maximize production capacity.

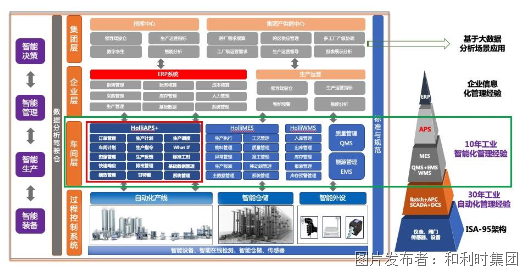

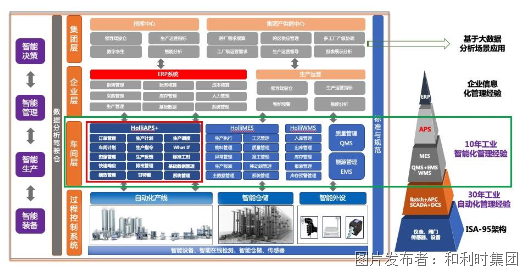

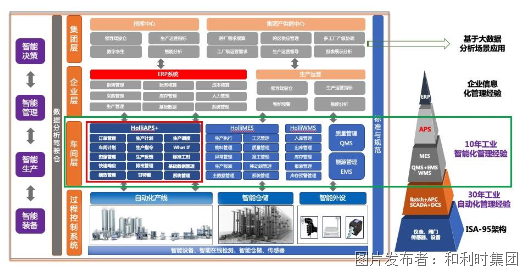

The advanced planning and scheduling system (APS+) with the combination of industry innovation and R&D meta model+NP+algorithm solves the problem of complex multi-level multi-objective optimization through the nested segmentation architecture of the meta model.

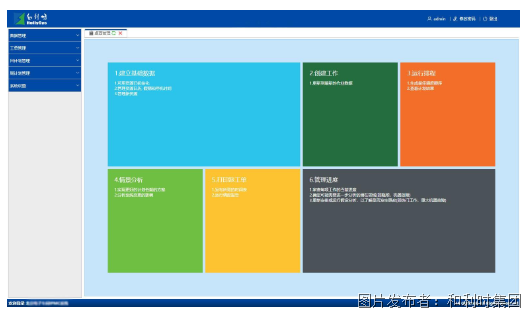

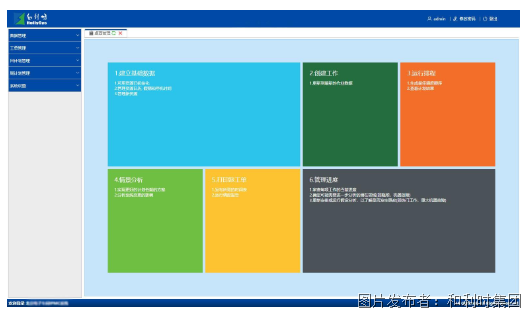

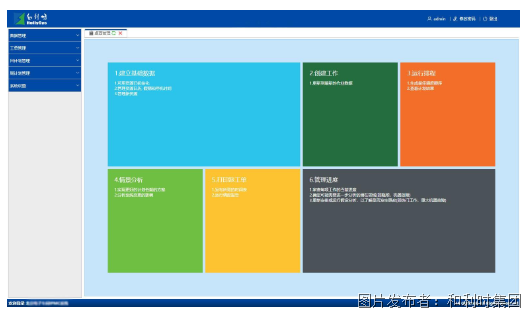

After investigation and analysis, this incubation project builds a digital platform (APS+) for enterprise production and operation plan decision management, and completes the integration of the original ERP The integration of MES, Batch and other software systems has developed an advanced optimization algorithm based on the nested segmentation framework and a solver for the fine chemical industry, which has realized rapid response to changes in production site planning and scheduling, output high-quality, high-precision second level scheduling results, improve the factory capacity and enhance the overall control and anti risk capabilities.

According to the current situation, modeling and analysis are carried out. After the project is completed, the following can be achieved:

Production efficiency improvement: increase the rationality and accuracy of the plan, output the optimized production scheduling scheme, and improve the utilization rate of the extruder

Improve resource utilization: reduce equipment idle time and improve overall equipment efficiency (OEE)

Improved delivery accuracy: due to the visualization of the order delivery date, the on-time delivery rate of customer orders will be significantly improved, shortening the delivery cycle, and the cycle from receipt to delivery of orders will be shortened, thus improving the market competitiveness

Hollysys Optimization focuses on operation planning, production planning and workshop scheduling in the manufacturing field, based on CPS theory (Cyber Physical Syst ems Cyber physical system) and nested segmentation method, to establish a complete multi-level perception analysis decision execution management control system, create its own industrial brain for enterprises, target the refined industry with heavy assets, high value, complex process and formula, high degree of automation, optimize workshop scheduling plan, provide planning and scheduling analysis, It has important economic benefits for maximizing production capacity.

In the future, Hollysys Optimization will uphold its technological innovation strength in product research and development as well as its profound industrial application practice, while deeply understanding the needs of industrial users, especially in the fine chemical industry, continue to promote the intelligent transformation of industrial users, develop new quality productivity, and actively promote the high-quality development of the fine chemical industry.