Configuring CANOpen to PROFINET gateway to connect LS series low voltage servo system We must systematically follow the following series of meticulous steps to ensure that the system connection is unimpeded. First of all, we should choose a suitable one CANOpen to PROFINET gateway, it needs to be compatible with our specific CANOpen and PROFINET devices. Next, we need to deeply study the manual of LS series servo system, just like an explorer looking for treasure, to collect the crucial parameter information in its CANOpen object dictionary, such as device ID, baud rate, node address, etc. These parameters will become the cornerstone of our subsequent configuration.  Then, we enter the link of physical connection, like building a bridge The CAN interface of LS series servo system is closely connected with the CANOpen port of the gateway, and then the PROFINET port of the gateway is skillfully integrated into the PROFINET network. So far, our hardware equipment has been built. Next, we need to log in to the gateway management interface to start the configuration journey. stay For CANOpen, we need to accurately set baud rate, node ID and other parameters to ensure smooth transmission of information. In the PROFINET part, we need to name and assign the PROFINET device ID and IP address to make it unique in the network. Later, we will The mapping between CANOpen and PROFINET data is like drawing an accurate map to ensure that the input and output data of LS servo system can be accurately transferred between the two protocols. This includes position, speed, torque, fault information and other key parameters, which will jointly plot the trajectory of the system operation.

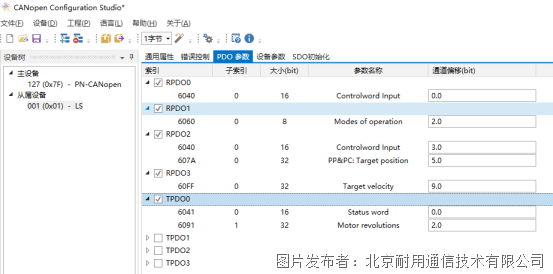

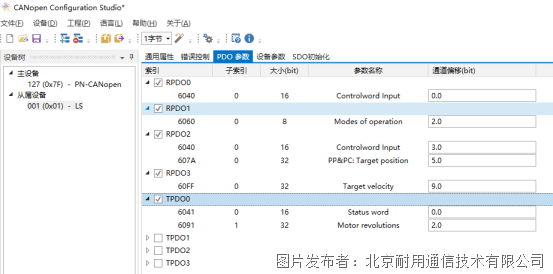

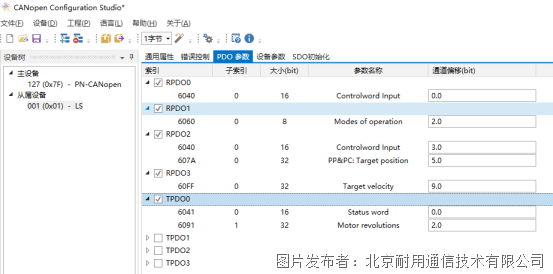

Then, we enter the link of physical connection, like building a bridge The CAN interface of LS series servo system is closely connected with the CANOpen port of the gateway, and then the PROFINET port of the gateway is skillfully integrated into the PROFINET network. So far, our hardware equipment has been built. Next, we need to log in to the gateway management interface to start the configuration journey. stay For CANOpen, we need to accurately set baud rate, node ID and other parameters to ensure smooth transmission of information. In the PROFINET part, we need to name and assign the PROFINET device ID and IP address to make it unique in the network. Later, we will The mapping between CANOpen and PROFINET data is like drawing an accurate map to ensure that the input and output data of LS servo system can be accurately transferred between the two protocols. This includes position, speed, torque, fault information and other key parameters, which will jointly plot the trajectory of the system operation.  In parameter synchronization, we need to ensure that The parameters between LS servo system and gateway are highly consistent, and they are like twins. Some parameters may need to be set separately in the two systems to ensure the accuracy and integrity of the information. Next, we start the gateway and PROFINET controller for communication test. Like detectives, we carefully check whether the data is transmitted correctly between the LS servo system and the control system, observe the response of the servo system, and ensure that it can act accurately according to the instructions of the PROFINET controller. According to the test results, we may need to fine tune the configuration to solve the possible communication delay or data loss problems. As craftsmen polish handicrafts, we strive for perfection.

In parameter synchronization, we need to ensure that The parameters between LS servo system and gateway are highly consistent, and they are like twins. Some parameters may need to be set separately in the two systems to ensure the accuracy and integrity of the information. Next, we start the gateway and PROFINET controller for communication test. Like detectives, we carefully check whether the data is transmitted correctly between the LS servo system and the control system, observe the response of the servo system, and ensure that it can act accurately according to the instructions of the PROFINET controller. According to the test results, we may need to fine tune the configuration to solve the possible communication delay or data loss problems. As craftsmen polish handicrafts, we strive for perfection.  Finally, we record all the configuration settings and network topology in detail, just like writing an operation manual to facilitate future maintenance and troubleshooting. At the same time, we will also use the monitoring and diagnostic tools provided by the gateway to regularly check the system status to ensure the long-term stable operation of the system. Please note that due to the gateway model and The specific models of LS series servo systems may be different, so the specific configuration steps and parameter settings may be different. Therefore, during the configuration process, be sure to refer to the relevant technical documents and manuals to ensure that every step is accurate.

Finally, we record all the configuration settings and network topology in detail, just like writing an operation manual to facilitate future maintenance and troubleshooting. At the same time, we will also use the monitoring and diagnostic tools provided by the gateway to regularly check the system status to ensure the long-term stable operation of the system. Please note that due to the gateway model and The specific models of LS series servo systems may be different, so the specific configuration steps and parameter settings may be different. Therefore, during the configuration process, be sure to refer to the relevant technical documents and manuals to ensure that every step is accurate.