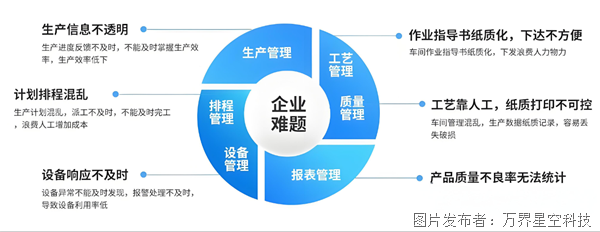

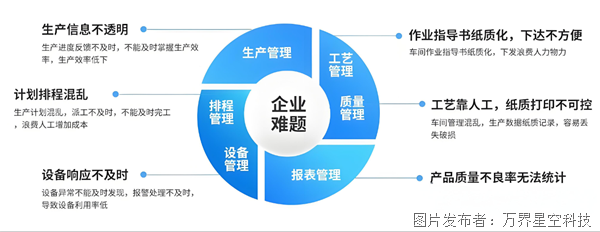

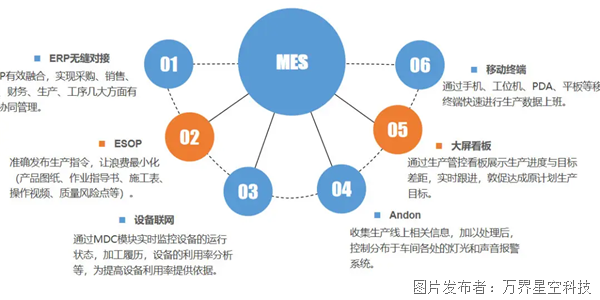

What problems can the MES system solve? along with Intelligent manufacturing More and more customers are aware of the importance of MES system, but what problems can MES solve.

1. Information communication

Through the MES system, managers can grasp the data information in production in real time, respond in time, reduce the efficiency waste and possible production problems caused by untimely communication with the MES system, improve efficiency and ensure the safe and orderly production process.

2. Curing process

The process flow is controlled through the MES system. The production process and specific operation can only be carried out in a fixed or limited way in the system, and can not be changed at will. It is also difficult to cut corners, reduce the cost of process management, as well as the production waste caused by no fixed process, and improve the efficiency of production and manufacturing.

3. Data acquisition

Manual data collection has been difficult to meet the management requirements of information production and manufacturing, and the efficiency of collection will be much worse.

The MES system with certain data acquisition hardware and technology can realize the automation and automation of data acquisition, greatly improving the efficiency of manual data acquisition, and even some data that cannot be collected manually can be collected, improving the comprehensiveness and accuracy of data acquisition.

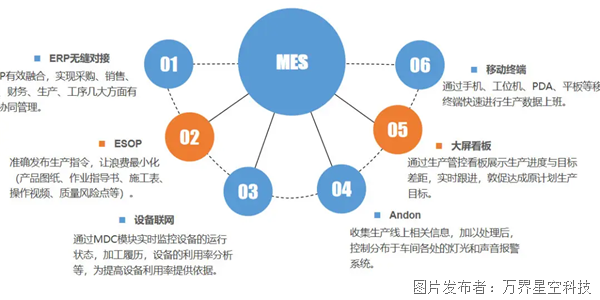

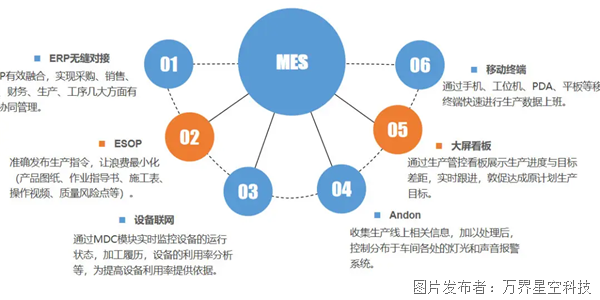

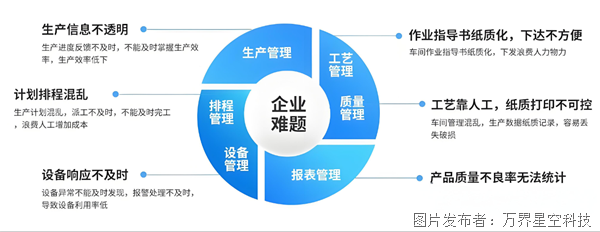

The implementation of MES system solutions is mainly to achieve the following goals:

1. Transparent manufacturing execution process to meet the internal management improvement needs of enterprises.

The solution of the MES system is to realize real-time collection of detailed production process data such as process output, process yield, work order WIP transfer status, test parameters, etc. through technical monitoring and equipment control, and provide a summary analysis report tool to provide effective data for the production management decisions of managers at different levels of the enterprise.

2. Shorten product manufacturing cycle and ensure enterprise benefits.

In order to shorten the product quality cycle, improve the degree of automated production, and replace and save a large number of manual work processes, Wanjie Star Technology MES system solutions. MES real-time information collection and feedback function can eliminate the delay caused by asymmetric information and improve the timely feedback rate of real-time conditions.

3. Improve product quality and continuously improve customer satisfaction.

The MES system solution provides quality control personnel with their own basic data and analysis tools for monitoring the whole production process of enterprises, and analyzes the daily quality of enterprises in real time. With this as a reference, the quality of enterprises can be continuously and periodically improved. The MES system solution mainly focuses on real-time monitoring and early warning of the production process, reducing the number of product maintenance and rework, saving communication tools, real-time paperless engineering production, and reducing the ineffective utilization rate of human resources and other resources.